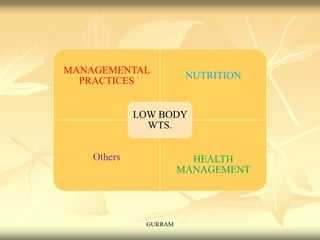

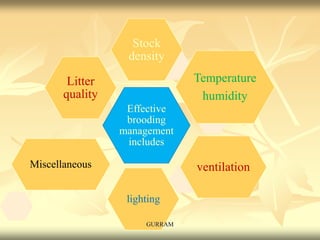

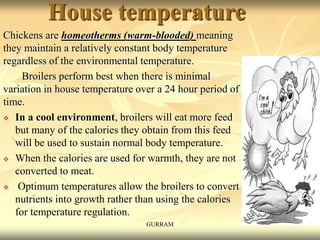

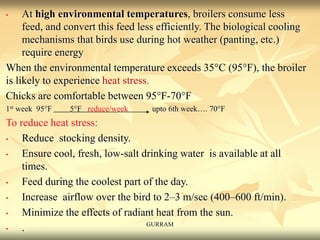

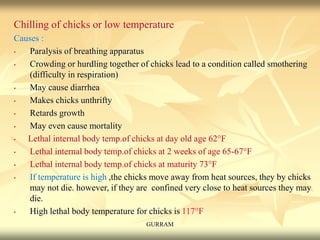

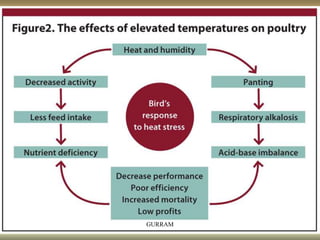

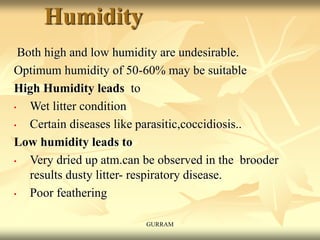

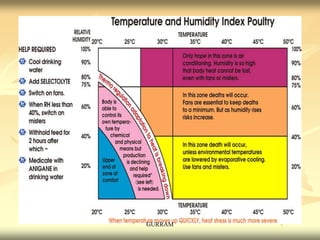

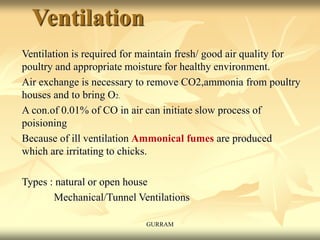

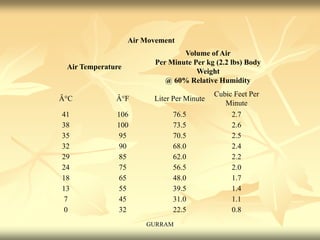

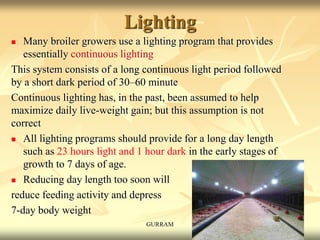

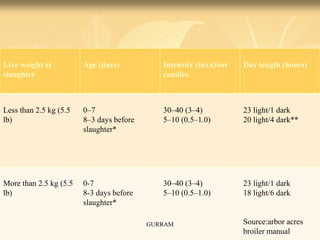

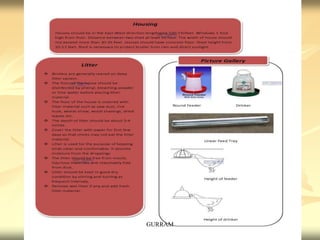

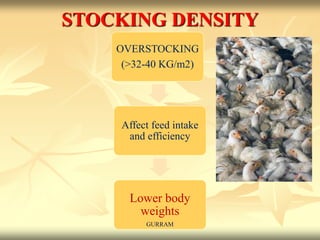

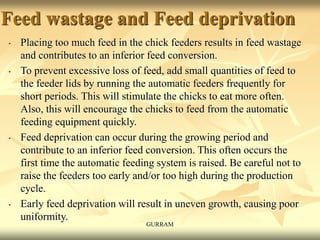

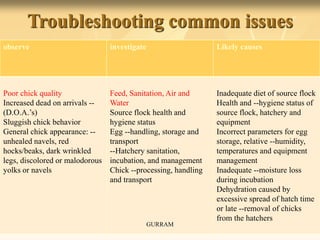

This document discusses reasons for low body weights in broilers and corrective measures. It covers several key factors that impact broiler growth and productivity including brooding management, house temperature, humidity, ventilation, lighting, litter quality, and stocking density. Effective brooding management and maintaining optimal temperatures, humidity, ventilation and other conditions allow broilers to efficiently convert feed into growth rather than using calories for temperature regulation.