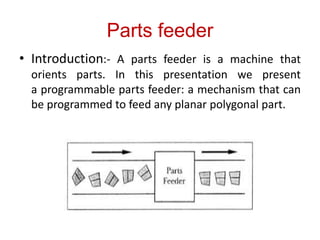

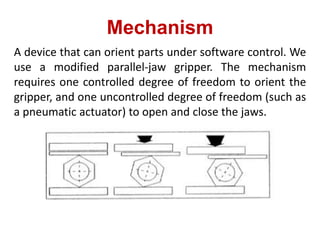

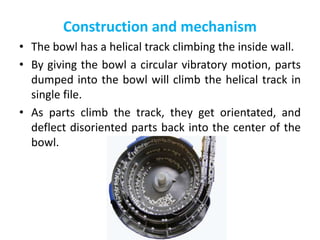

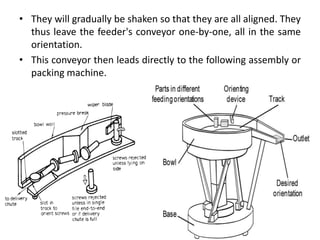

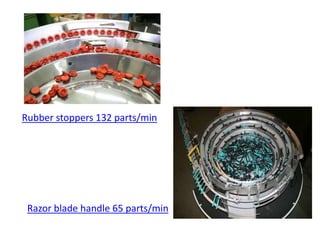

The document discusses different types of parts feeders. It describes a programmable parts feeder that can be programmed to feed any planar polygonal part. The key components are a feeding mechanism that can orient parts under software control and a planning algorithm to transform part descriptions into feeding programs. Conical bowl feeders are also described, which use vibration and a helical track to sequentially feed and orient parts leaving the feeder aligned and ready for assembly. Parts feeders provide flexibility over manual labor and reduce costs for manufacturers.