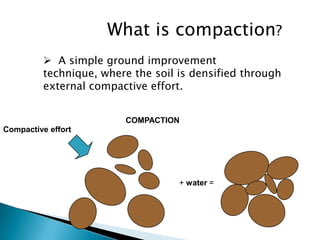

Compaction is a ground improvement technique that densifies soil through external effort like rolling, ramming, or vibration. Rolling uses heavy cylinders to compact soil surfaces like sports pitches. Ramming involves dropping a heavy block or mechanical rammer onto soil. Vibration compactors include vibratory rollers, plates, and tampers used in confined areas. Laboratory tests determine optimum water content and maximum dry density for different soils and compactive efforts like standard and modified Proctor tests.