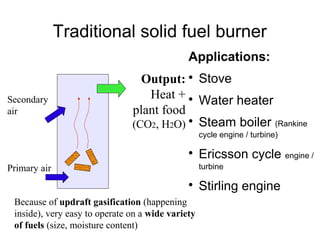

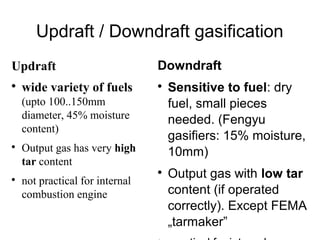

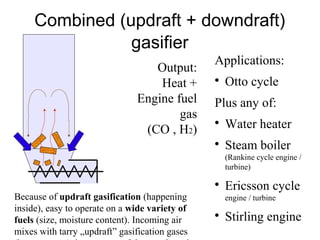

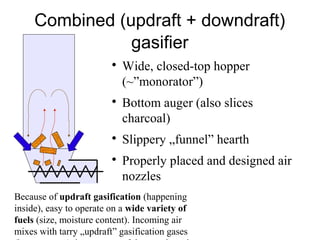

The document describes a combined updraft and downdraft gasifier that was developed as part of research project in Hungary. Traditional gasifiers are very sensitive to fuel size and moisture content, but the combined gasifier can operate on a wide variety of fuels. It has a higher turn-down ratio than other designs, allowing it to efficiently produce gas from a range of fuel amounts. The gas can be used in small Otto cycle engines for applications like combined heat and power plants.