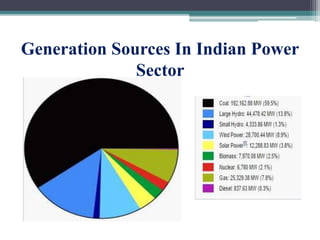

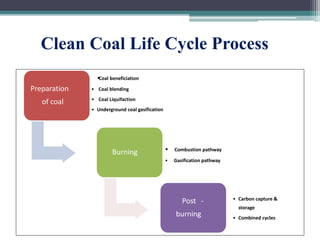

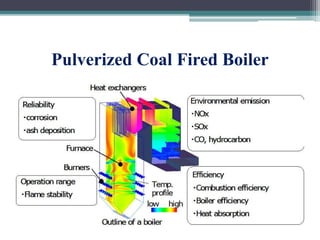

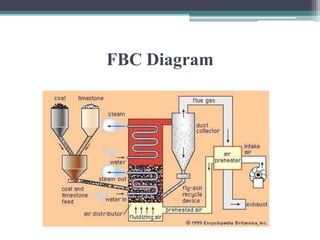

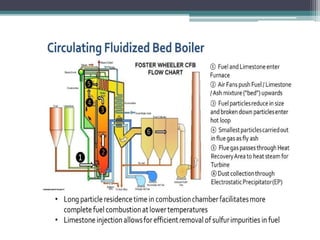

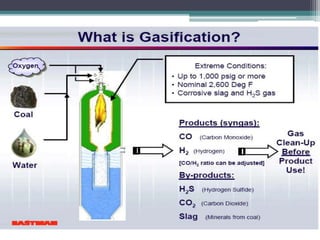

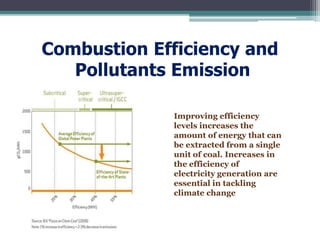

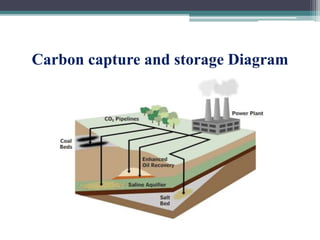

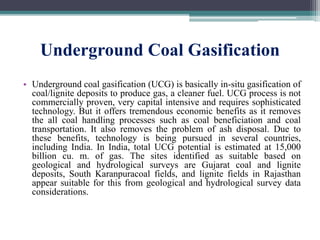

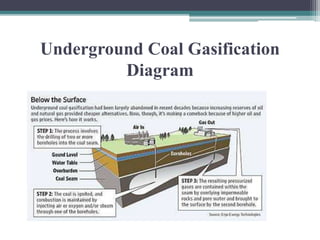

India relies heavily on coal for electricity but coal has environmental impacts. Clean coal technologies can reduce emissions. Technologies discussed include pulverized coal boilers, fluidized bed combustion, gasification, integrated gasification combined cycles, carbon capture and storage, underground coal gasification, and combined cycles. These technologies provide more efficient power generation with fewer emissions. For India, implementing supercritical plant technologies, assessing new technologies, and tightening emissions controls can help push clean coal development in the short and medium term while keeping long term technology options open. Overall clean coal technologies are promising for reducing the environmental impacts of power generation.