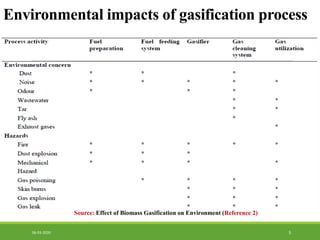

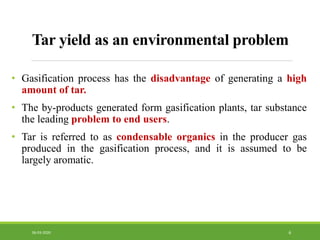

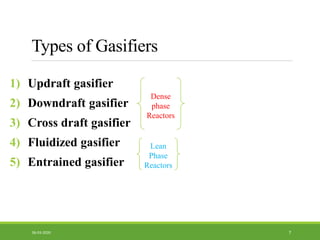

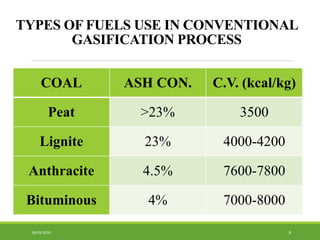

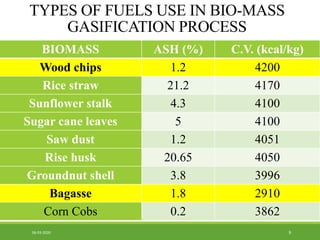

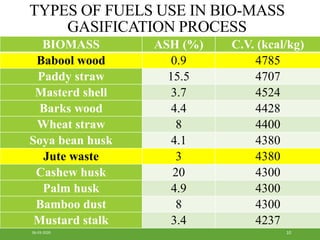

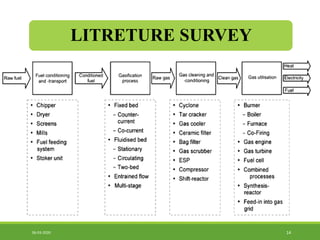

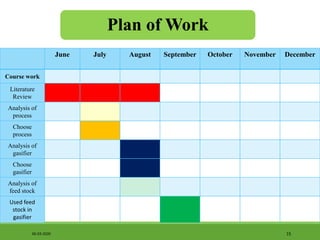

The document summarizes a biomass gasifier project undertaken by students. It includes the objectives to maximize gasifier efficiency and reduce tar production. It provides an introduction to gasifiers and discusses literature reviewed. The document outlines the plan to characterize catalysts, study reaction kinetics, and develop a model. It also lists common biomass and coal feedstocks and their properties. Applications of producer gas for heat and power are mentioned.