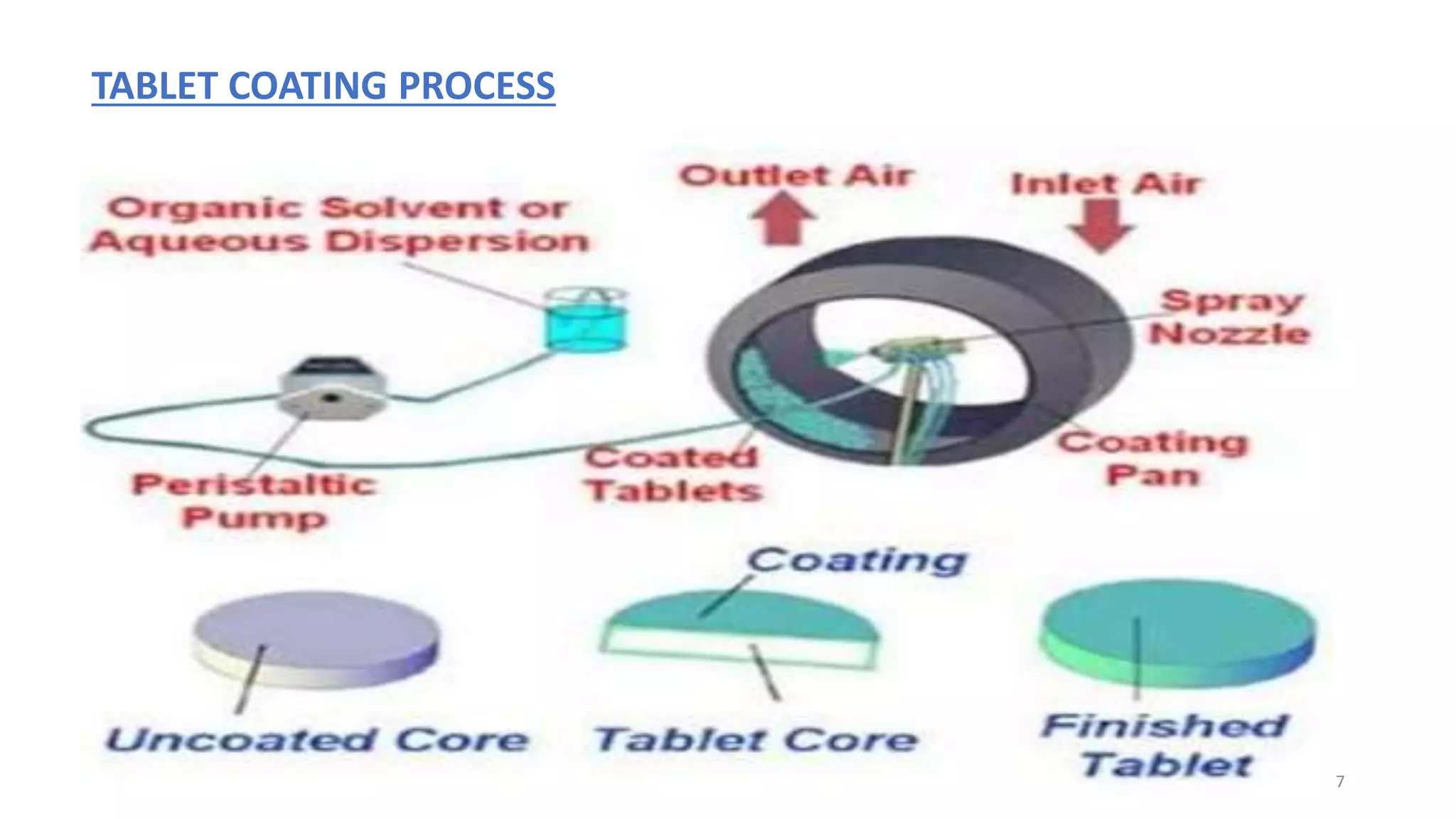

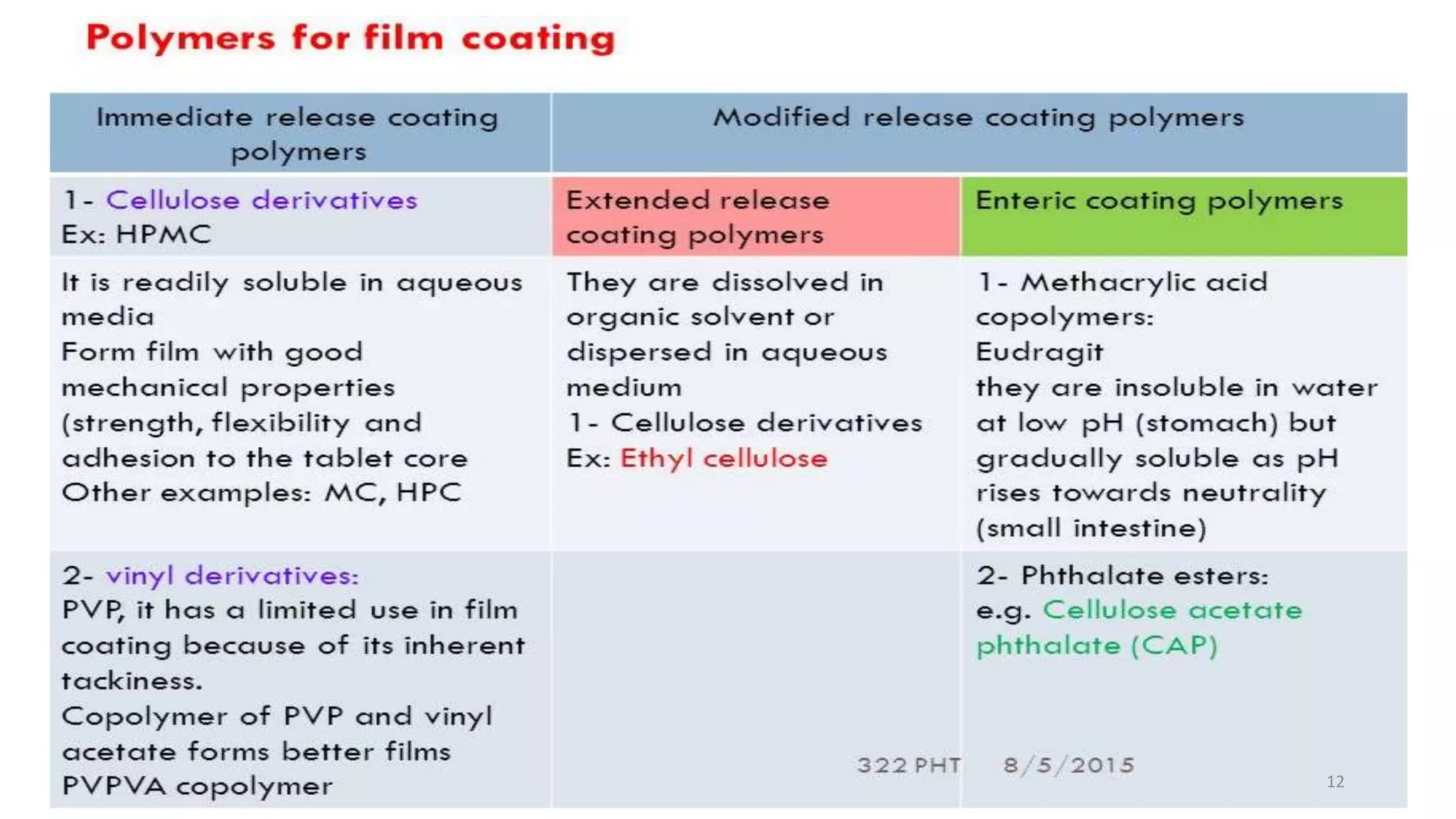

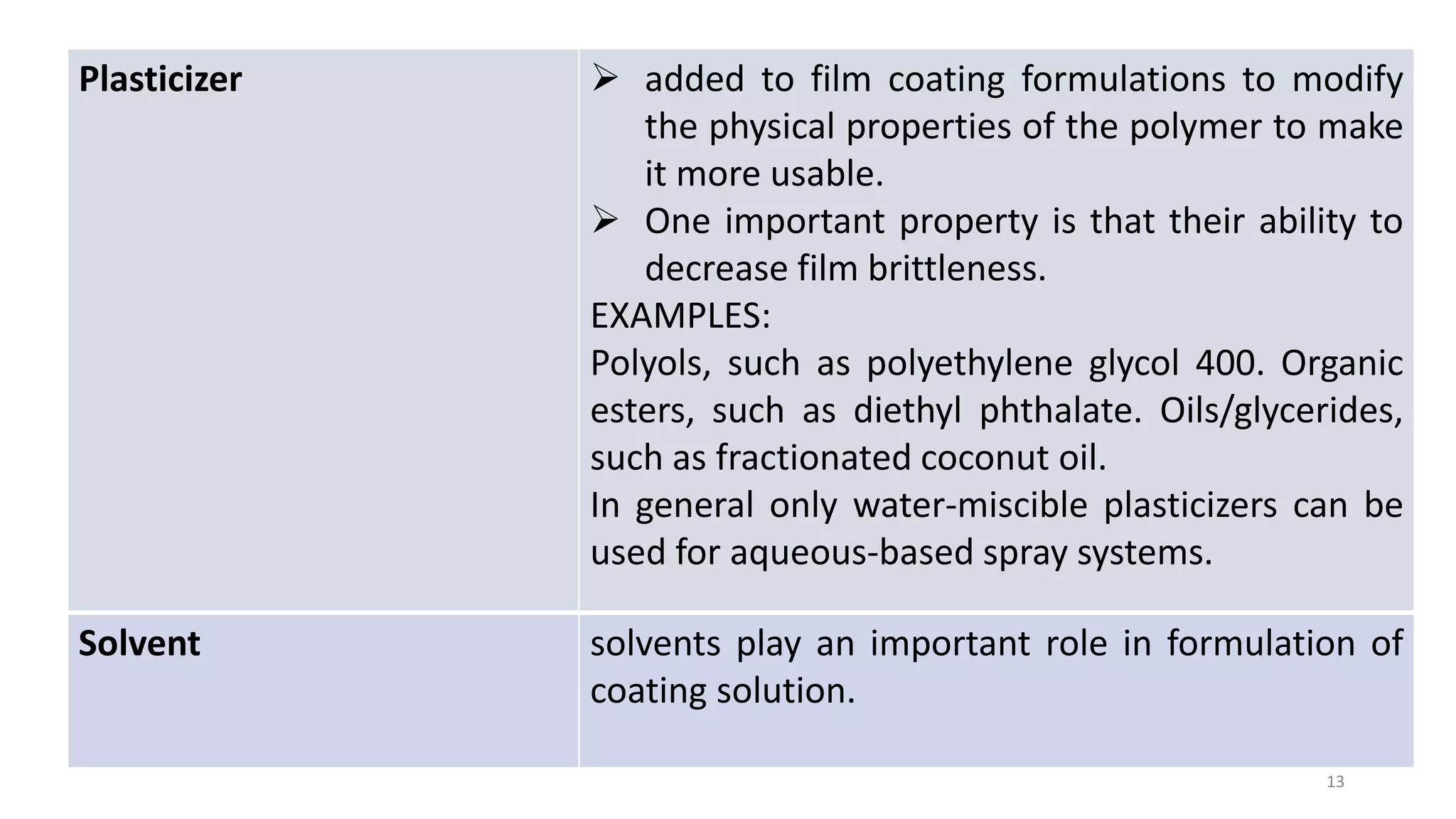

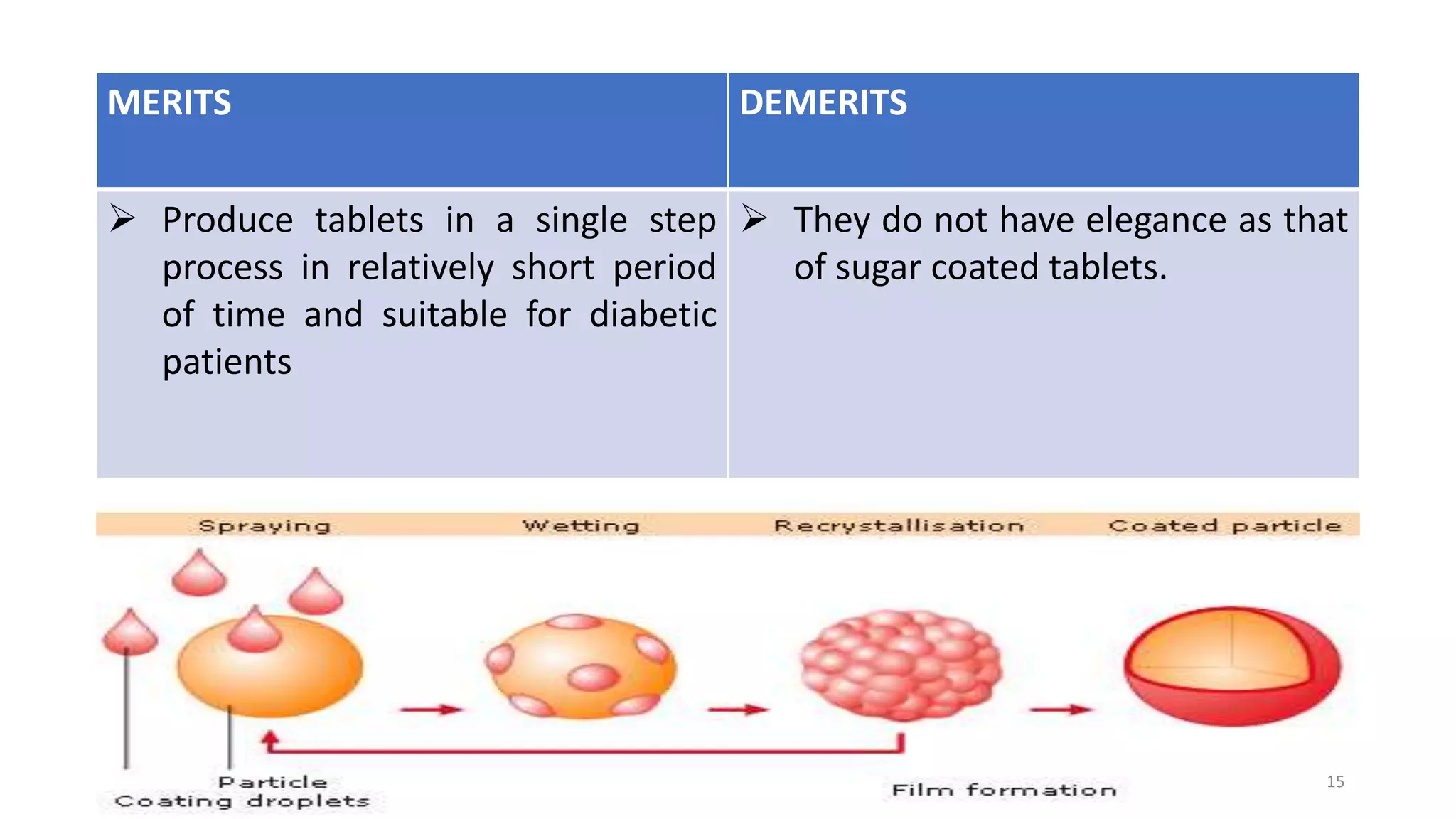

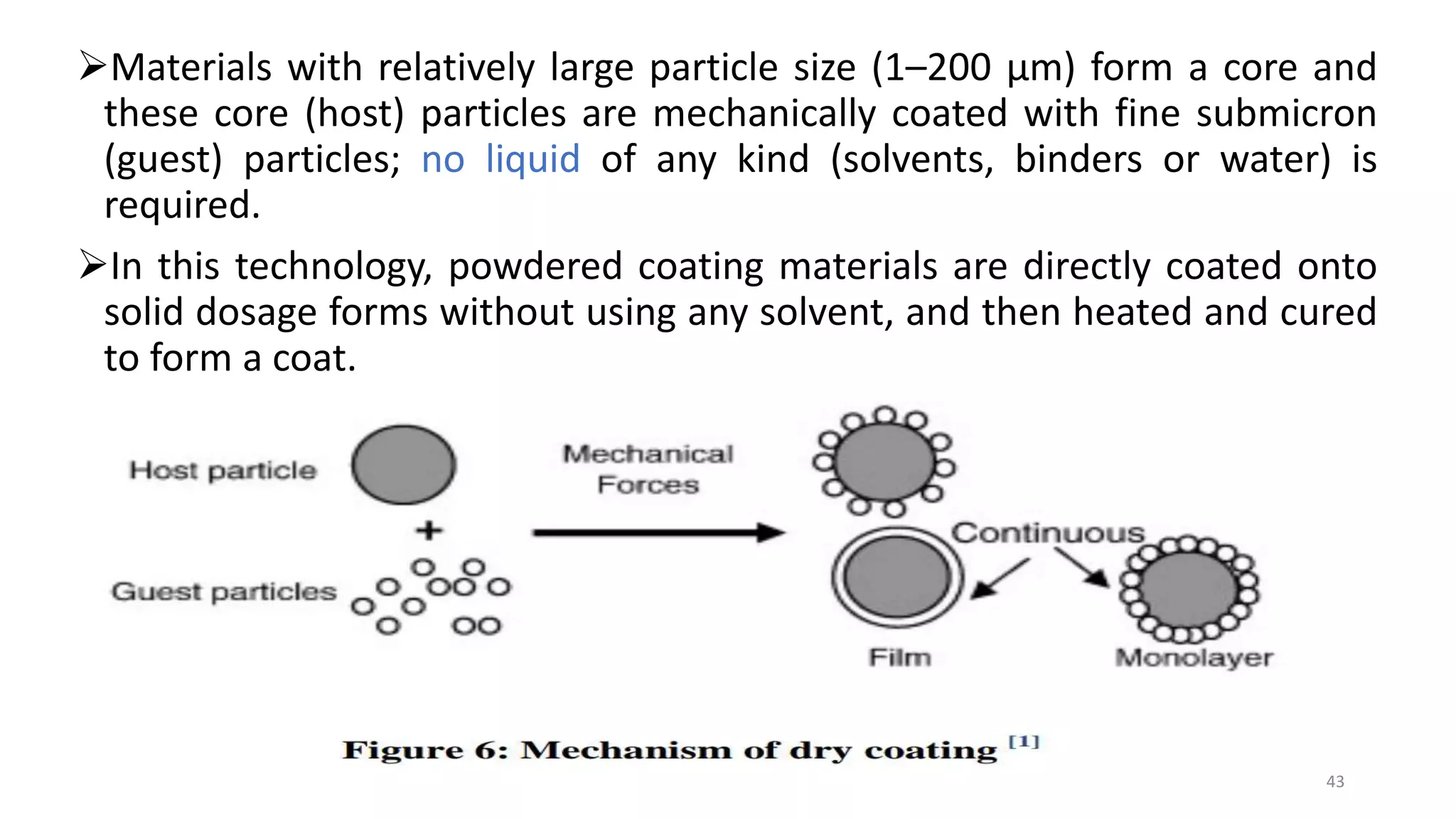

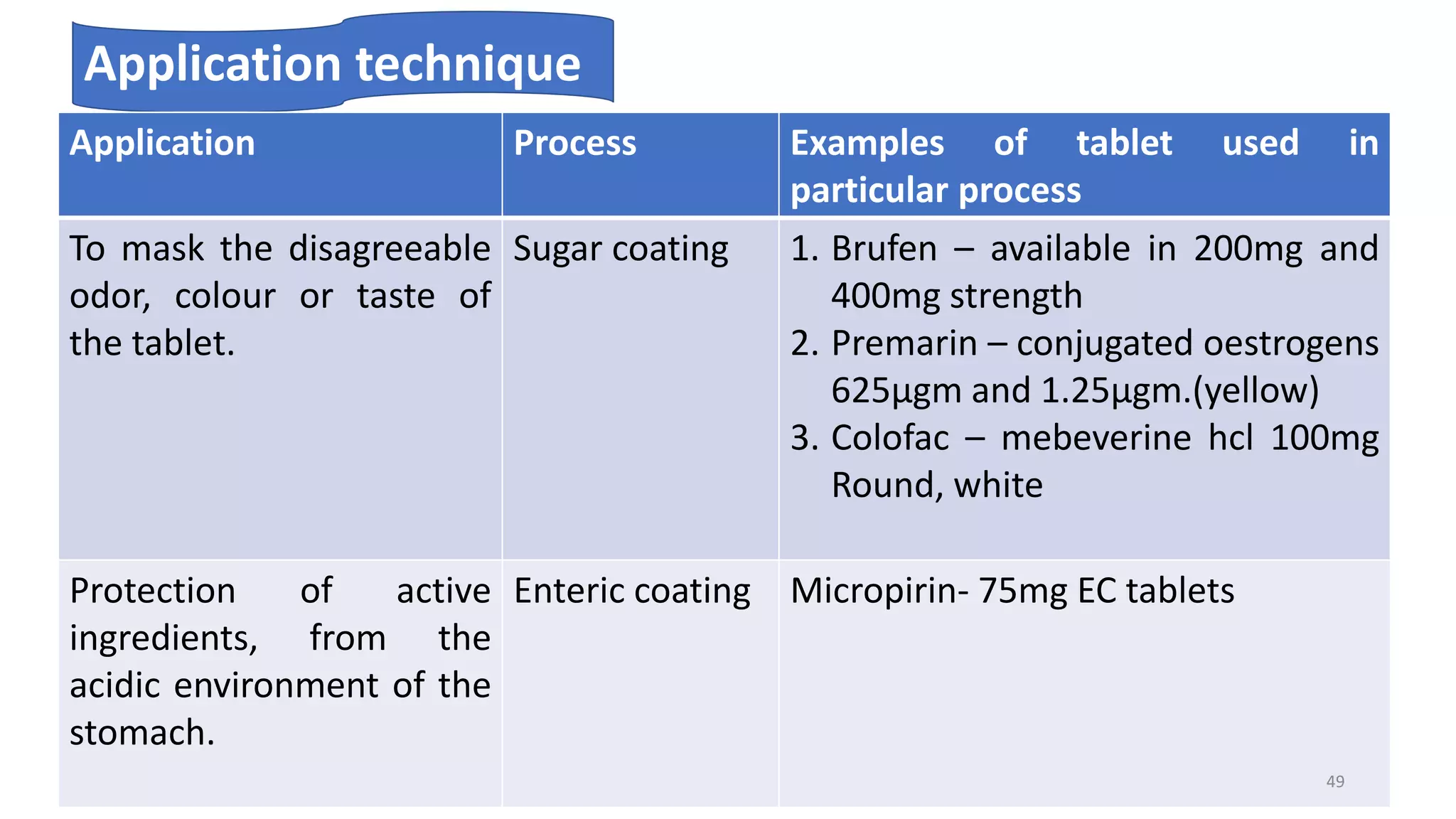

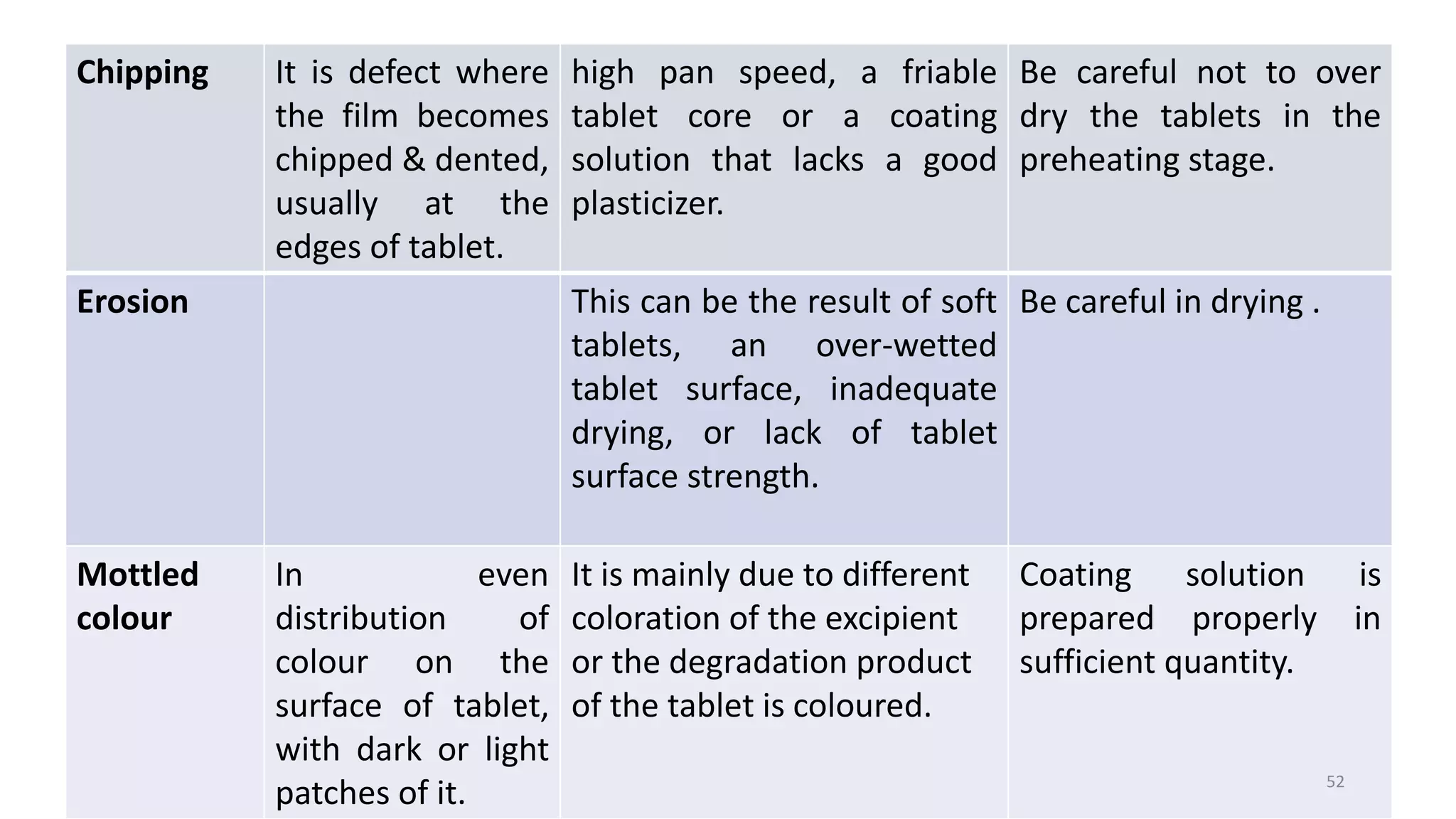

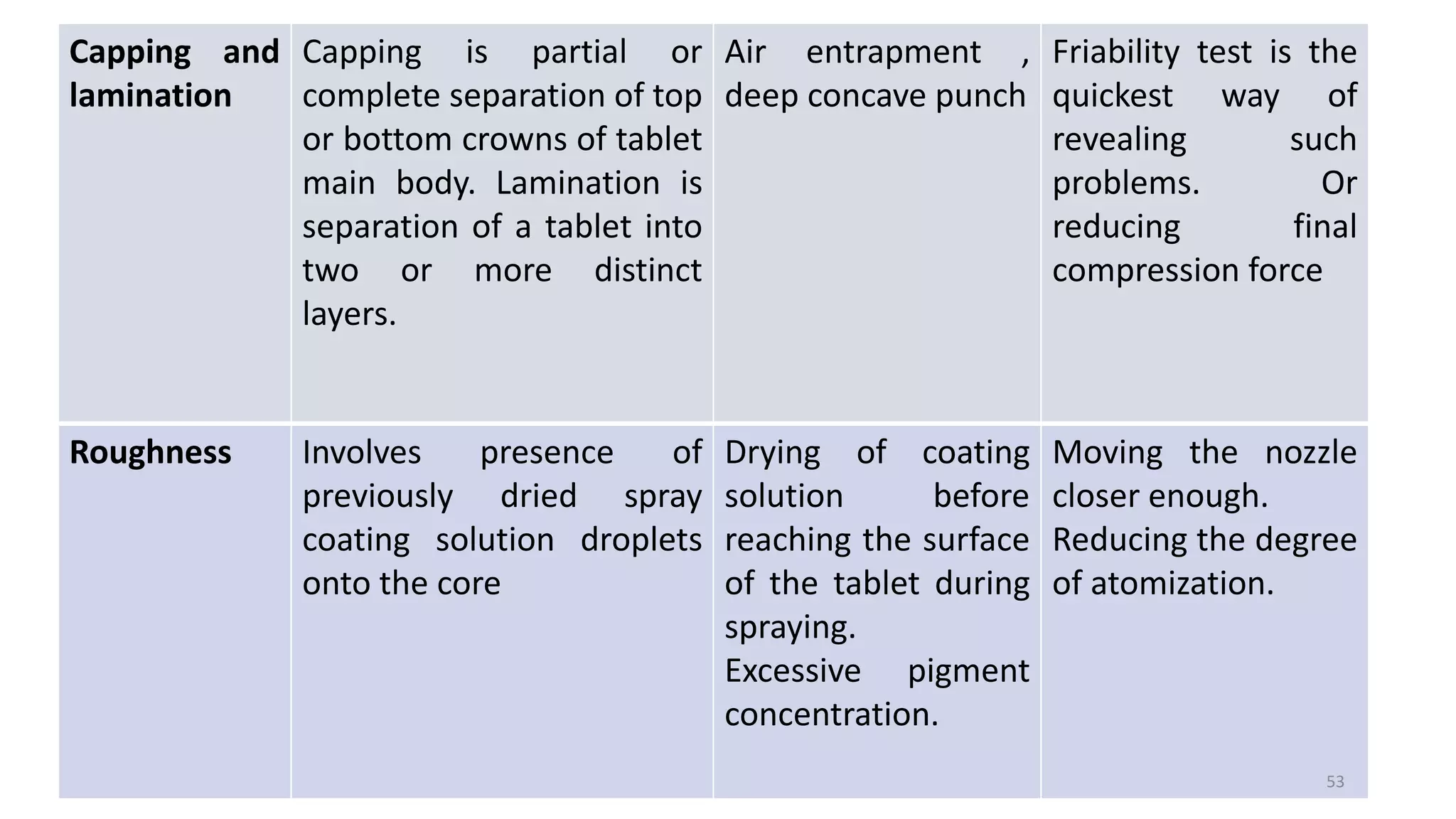

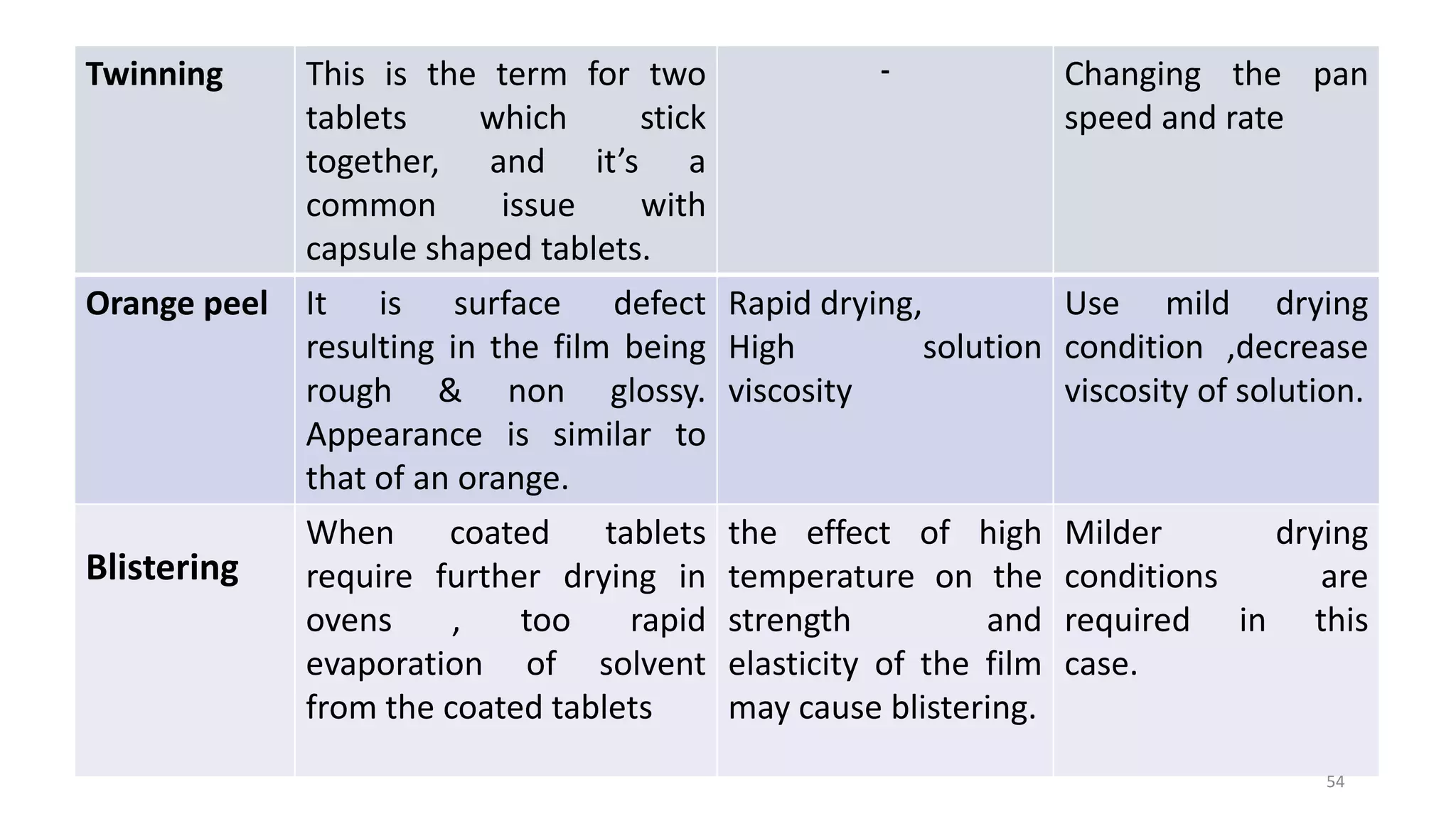

The document discusses various coating techniques used in pharmaceutical manufacturing. It describes common coating processes like sugar coating, film coating, enteric coating, and organic film coating. Recent coating technologies like electrostatic coating, vacuum film coating, compression coating, and dip coating are also summarized. The key equipment used for tablet coating include standard coating pans, perforated coating pans, and fluidized bed coaters. Coating is done to mask taste/odor, provide protection, control drug release, and incorporate incompatible drugs among other objectives.