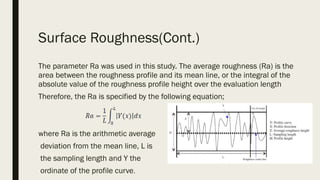

The document discusses various coating processes for cutting tools, emphasizing the differences between coated and uncoated carbide inserts in terms of tool life and surface roughness during metal cutting. It highlights the impact of cutting speed, feed rate, and depth of cut on these factors, showcasing that coated tools generally outperform uncoated ones. The study also details the experimental setup, techniques, and significant findings related to tool performance and surface quality.