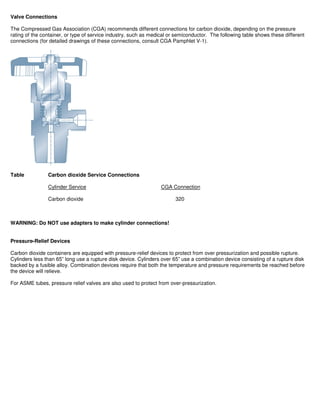

Carbon dioxide is a colorless, odorless gas that is slightly acidic and heavier than air. It has many commercial uses including carbonating beverages, freezing foods, and controlling chemical reactions. While non-toxic at normal levels, high concentrations can cause asphyxiation by displacing oxygen. Carbon dioxide is transported and stored in high-pressure cylinders or cryogenic liquid tanks, which require specialized valves, connections, and safety precautions due to its compressed state.