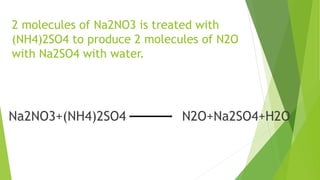

The document discusses medical gases, including their components, containers, production processes, and packaging/labeling. The key gases covered are oxygen, nitrogen, carbon dioxide, nitrous oxide, and helium. Oxygen production methods described are fractional distillation of liquid air and electrolysis of water. Cylinders and liquid storage tanks are used as containers. Strict labeling requirements include the batch number, production/expiry dates, quantity, and supplier information. Proper packaging and labeling controls are important for medicinal gases.