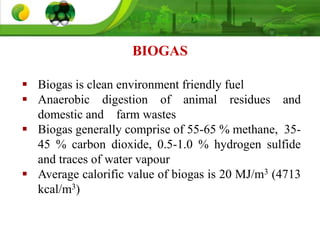

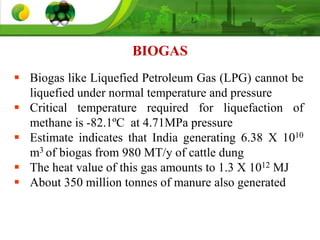

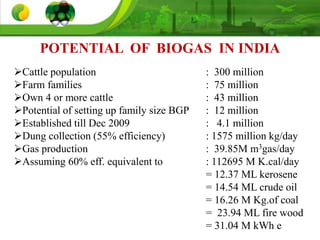

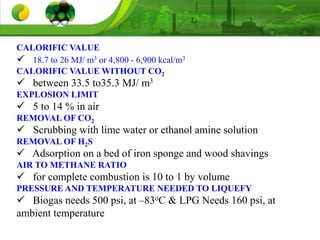

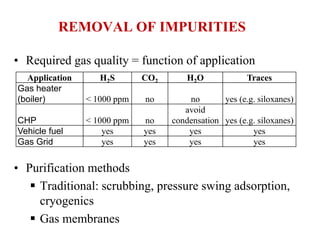

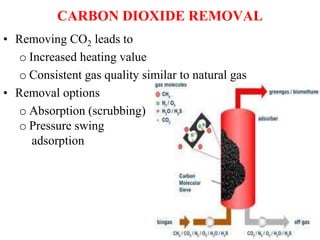

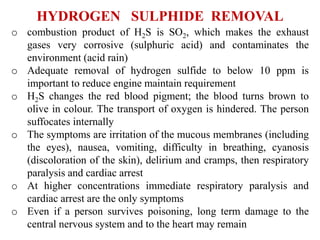

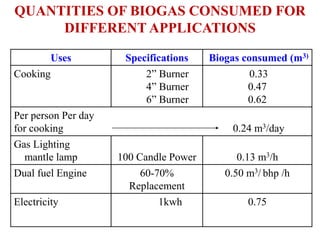

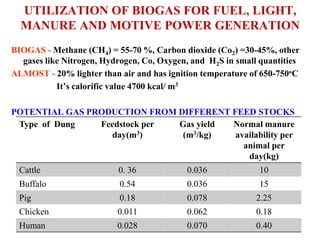

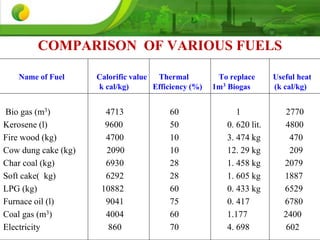

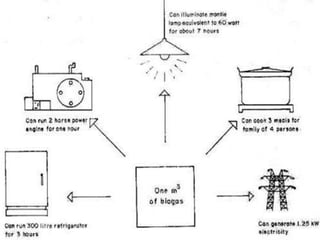

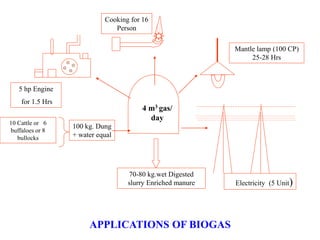

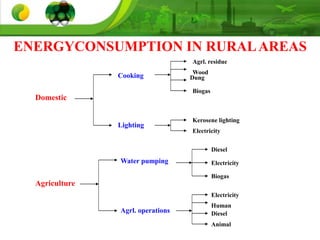

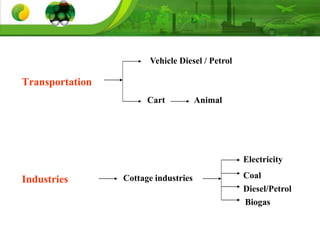

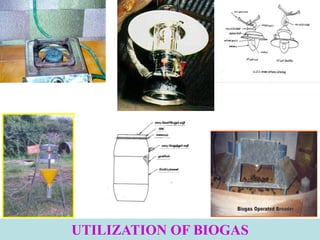

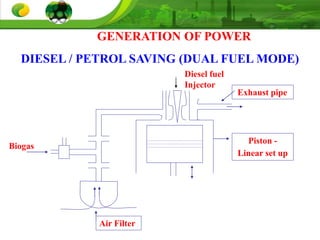

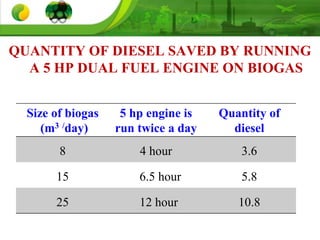

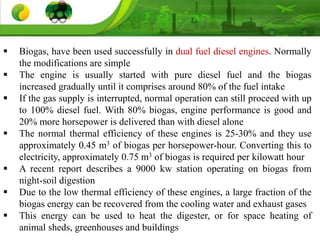

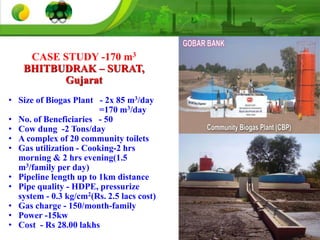

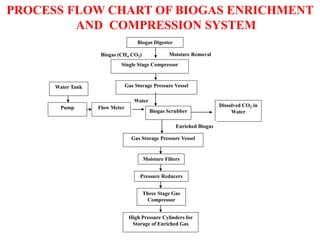

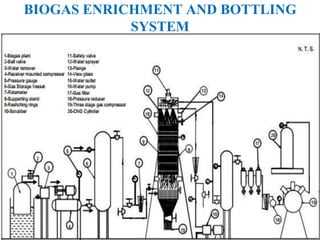

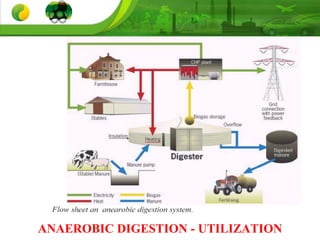

The document discusses the purification and utilization of biogas, a clean and environmentally friendly fuel generated from the anaerobic digestion of organic waste. It highlights India’s biogas potential, methods for purifying biogas by removing impurities such as carbon dioxide and hydrogen sulfide, and compares its calorific value to other fuels. Additionally, it examines applications of biogas for cooking, lighting, and power generation, emphasizing its benefits in improving rural livelihoods and reducing greenhouse gas emissions.