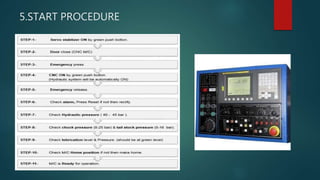

This document provides an overview of CNC programming and operation skills training at the Government Tool Room and Training Centre in Hassan. It introduces the GTTC and its facilities for CAD/CAM and advanced manufacturing techniques. It then covers the basics of CNC machines, including their typical elements, how they work through G and M codes, the start procedure, programming fundamentals, and format of blocks. The document also discusses advantages like easier programming and complex geometry production, and disadvantages such as high costs and needing skilled operators.