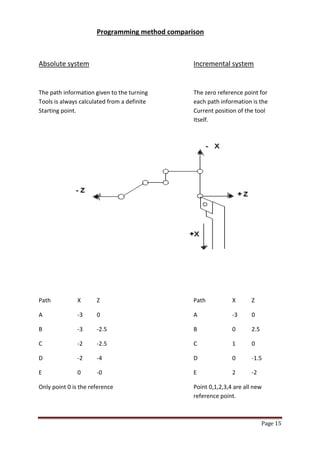

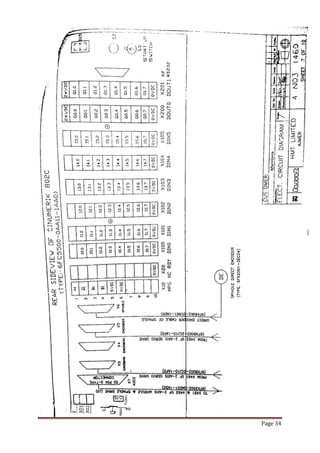

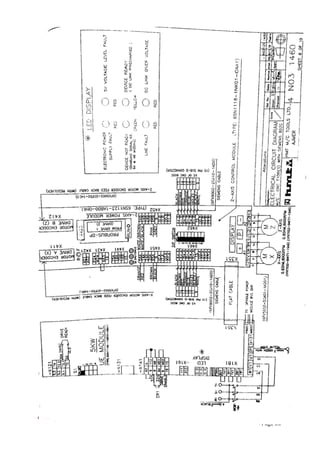

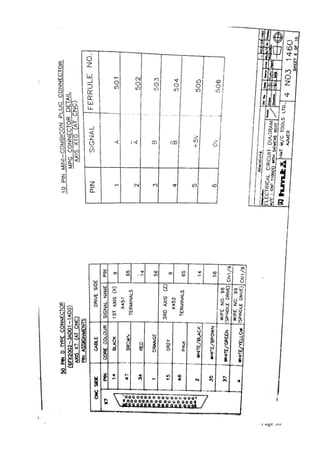

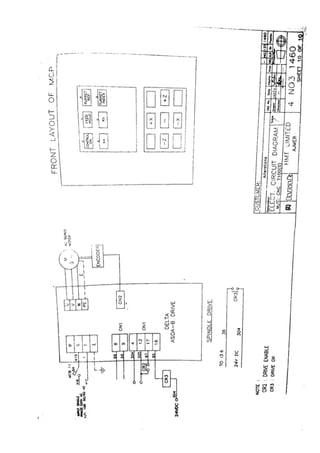

This document provides information about a CNC Train Master Lathe model CNC T-100(S). It includes specifications of the lathe such as dimensions, spindle speeds, feeds, and details of the mechanical components. It also describes the features and operation of the Siemens 802C CNC system including jogging, reference point approach, programming methods, and tool setting. The document is intended to train operators and engineers on CNC turning operations using this lathe.