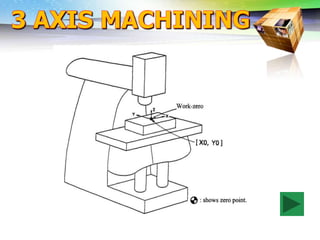

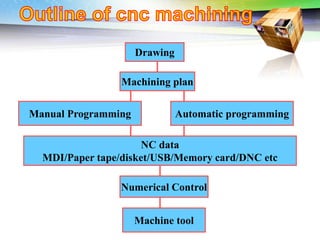

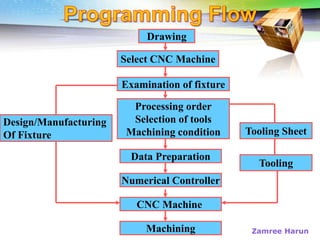

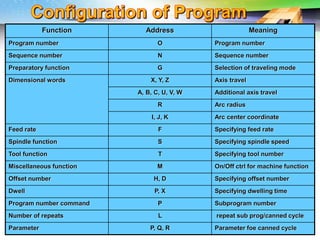

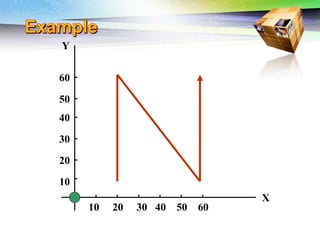

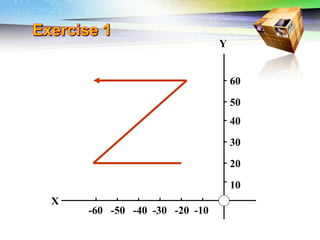

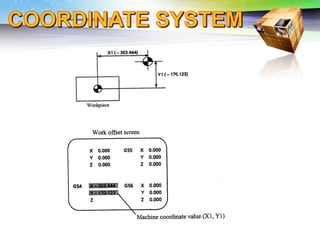

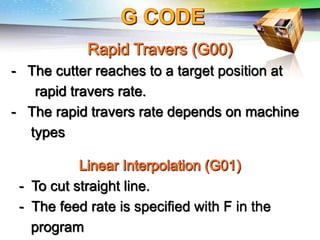

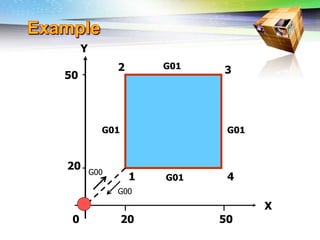

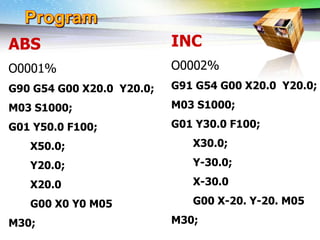

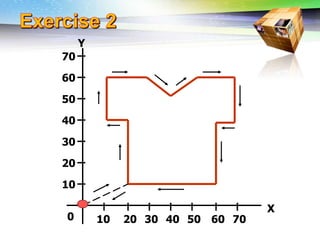

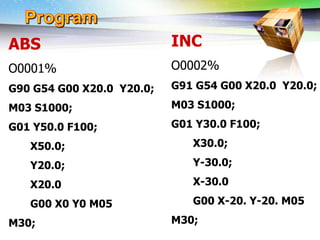

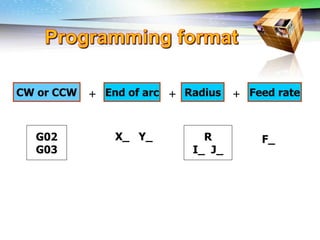

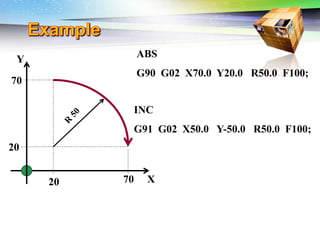

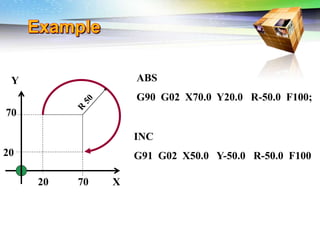

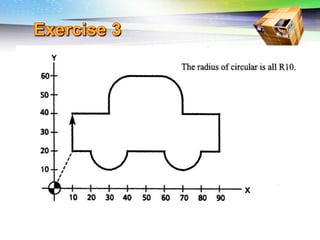

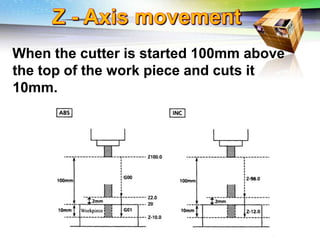

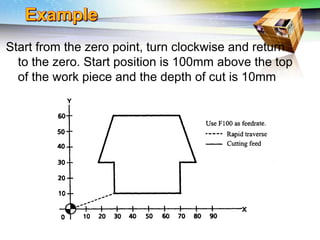

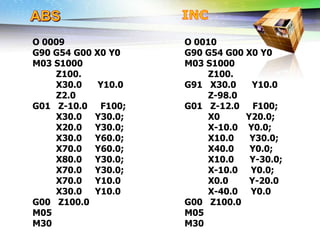

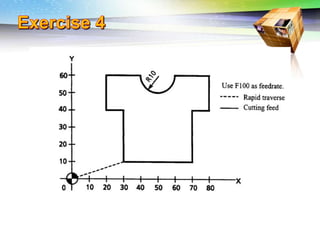

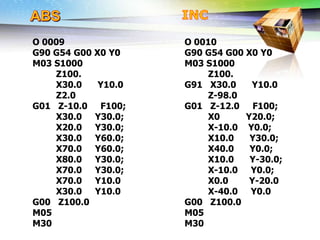

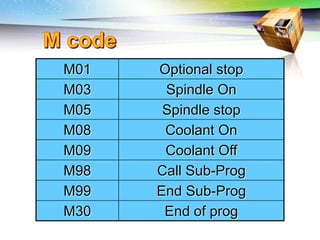

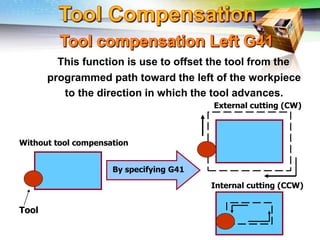

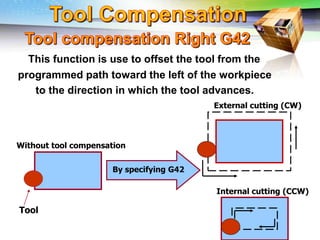

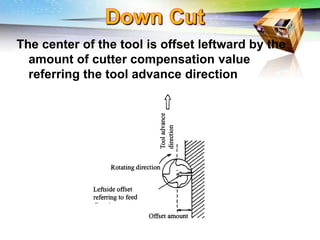

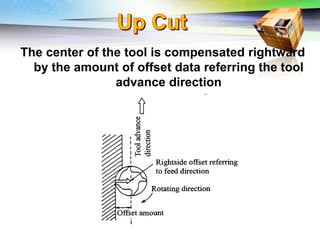

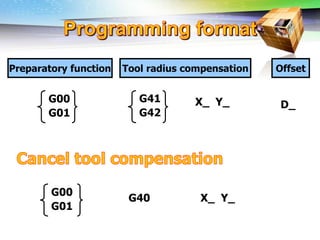

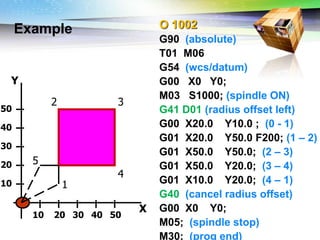

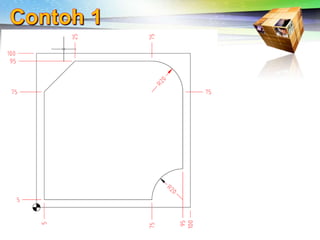

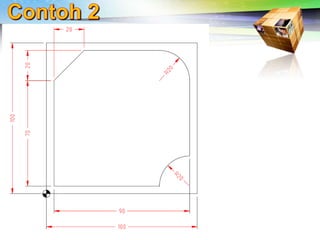

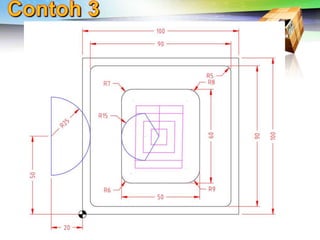

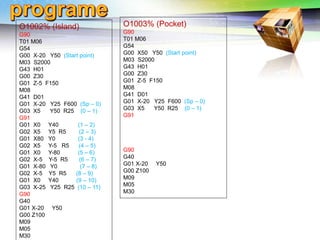

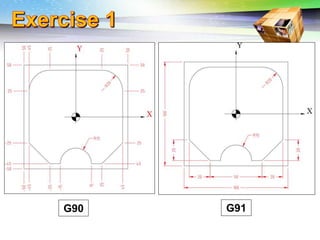

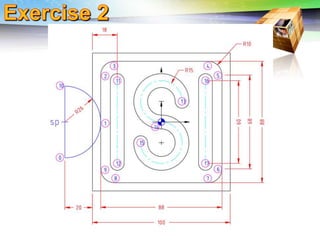

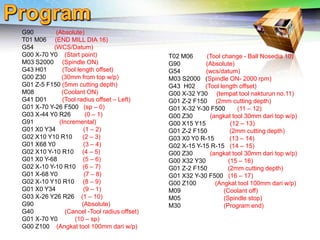

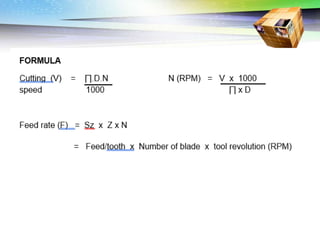

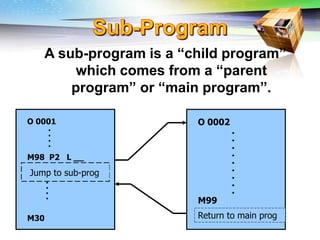

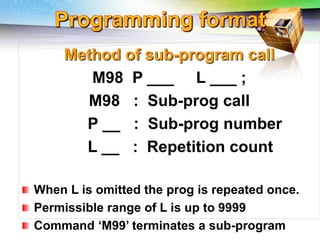

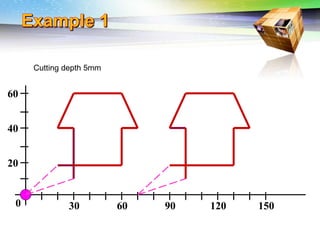

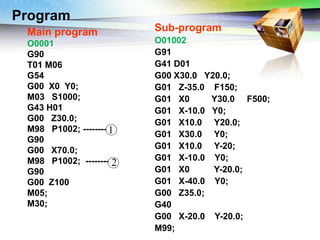

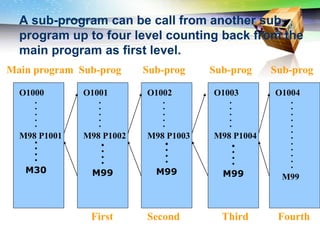

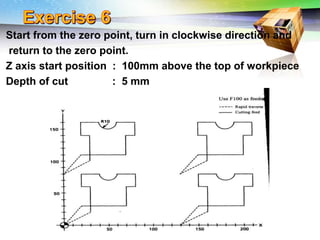

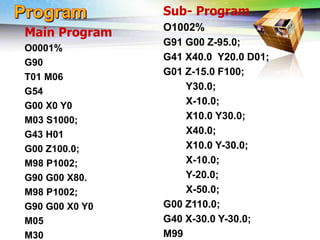

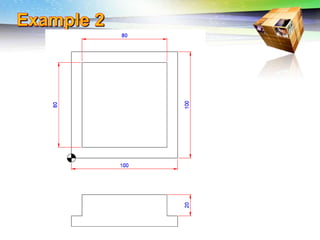

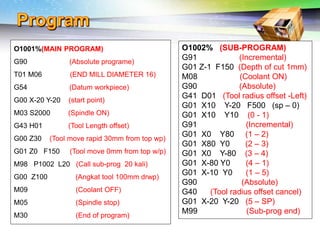

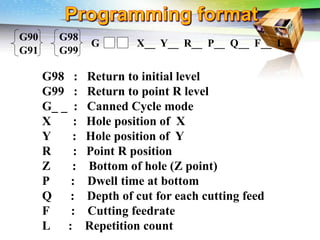

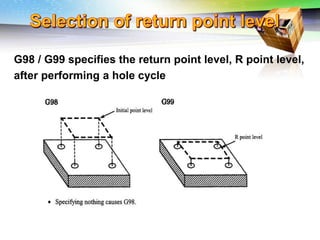

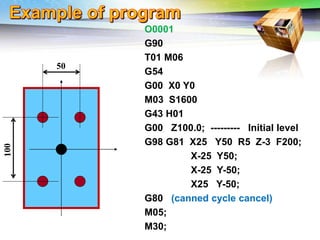

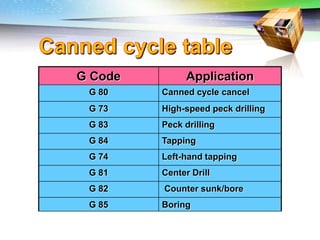

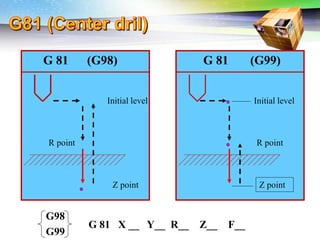

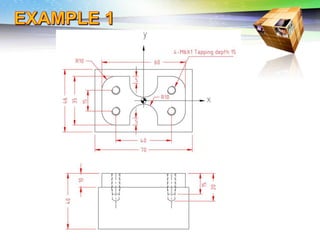

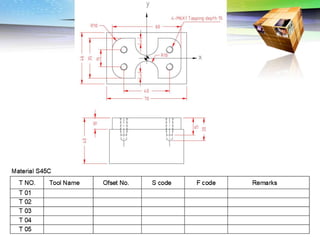

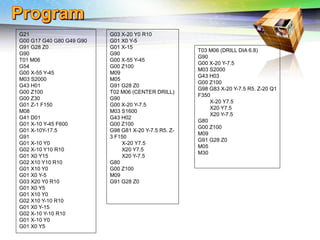

The document discusses the challenges of 5-axis machining. It begins by presenting an overview of the 5-axis machining process which includes drawing, machining planning, tool selection, fixture design, data preparation, and actual machining. It then covers challenges such as programming methods, coordinate systems, cutting motions, circular interpolation, subprograms, miscellaneous functions, tool radius compensation, and absolute and incremental programming. Examples of G-code programs for different 5-axis machining operations are provided and explained.