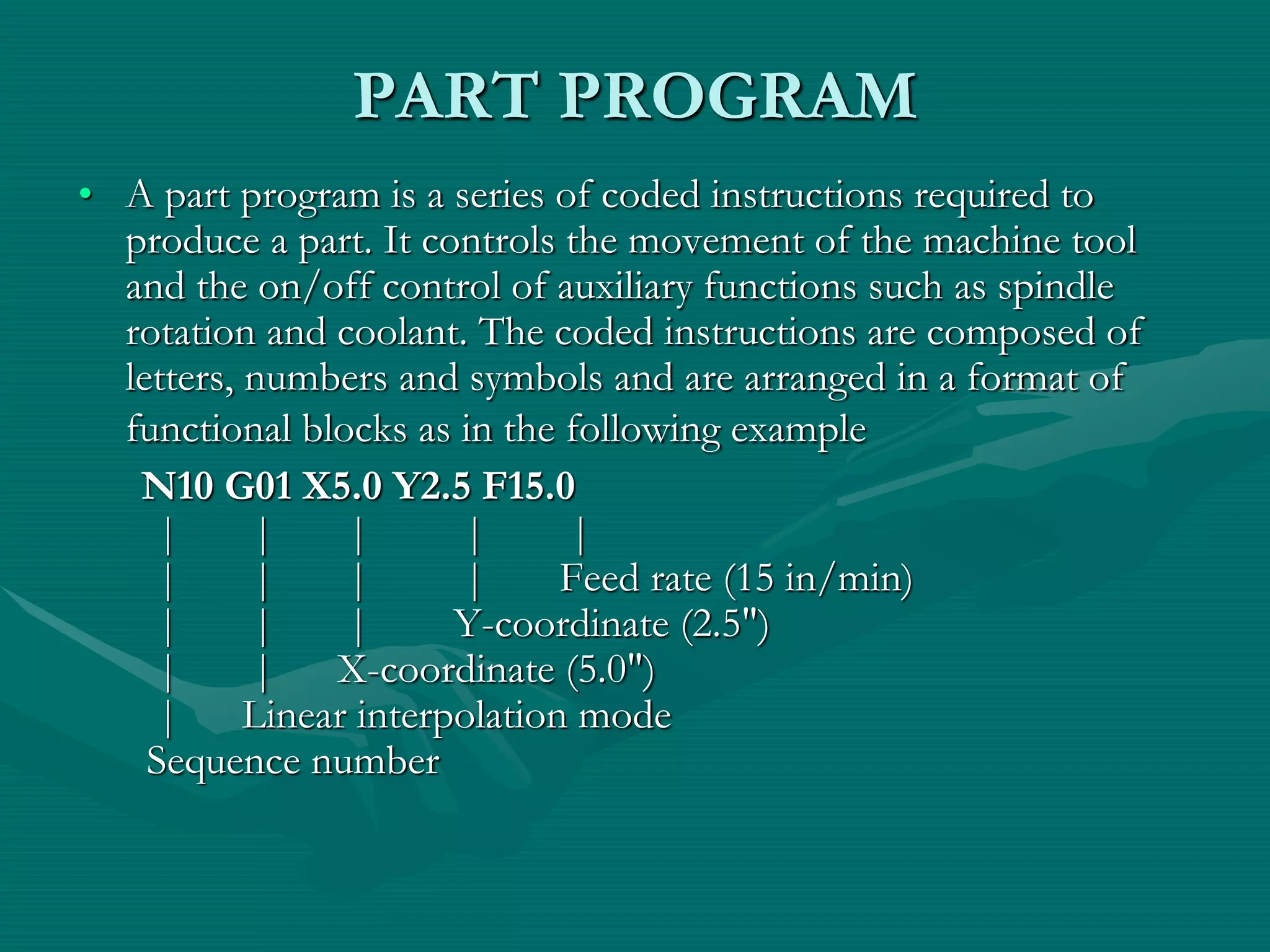

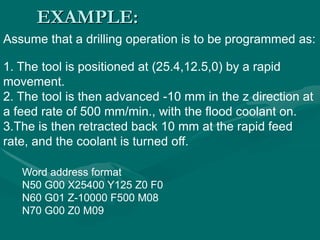

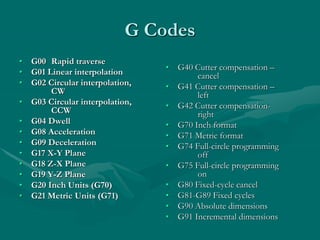

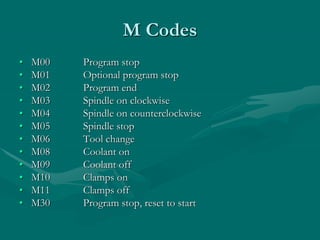

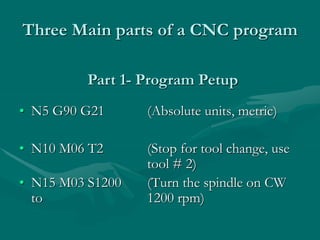

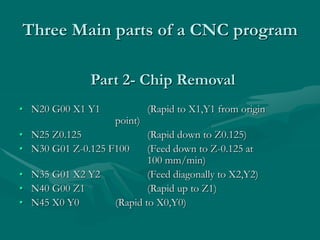

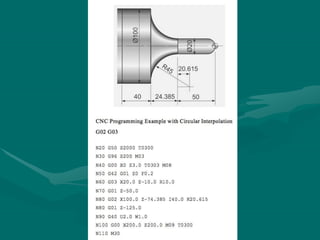

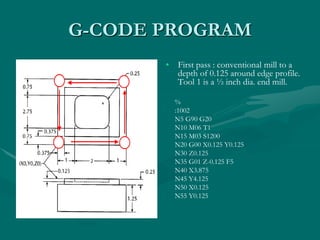

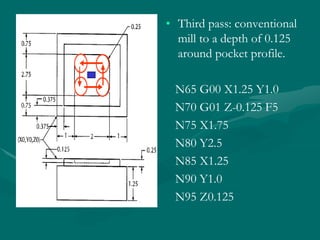

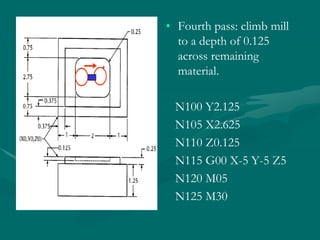

A part program is a series of coded instructions that controls a CNC machine tool to produce a part. It includes code for positioning the tool, controlling spindle speed and coolant, and instructions for linear and circular interpolation motions. A typical program has three main parts - the program setup with codes for units and tool selection, the chip removal section with pathing and feedrate codes, and a system shutdown section to stop the spindle and end the program. G-codes specify modes like rapid traverse or linear interpolation while M-codes control auxiliary functions. Together this code instructs the machine tool to make the necessary motions to machine a part's features.