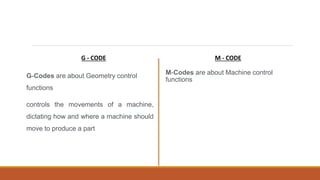

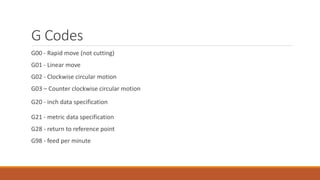

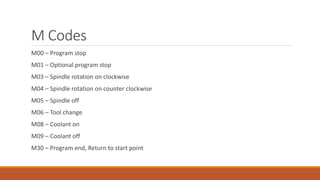

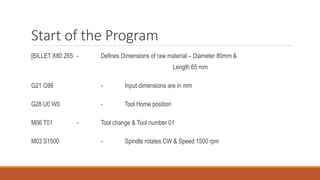

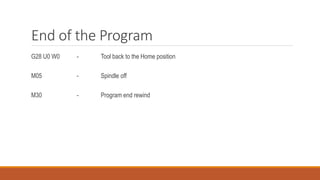

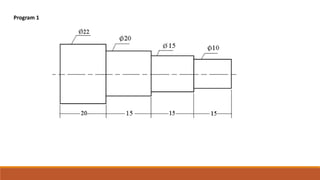

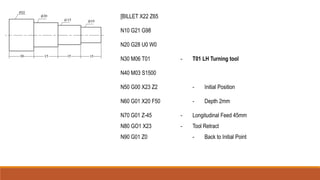

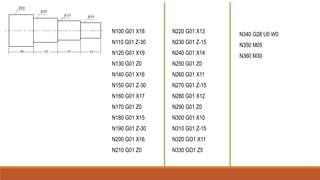

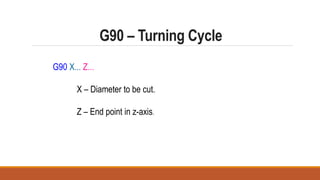

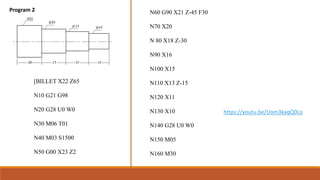

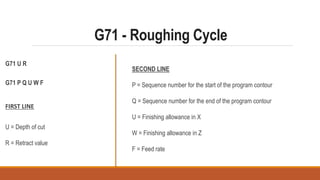

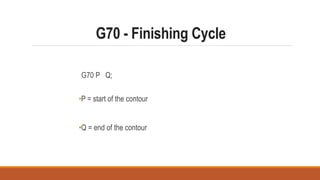

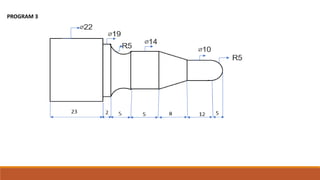

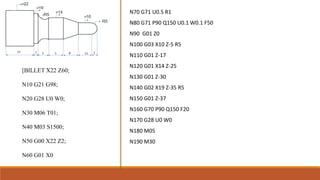

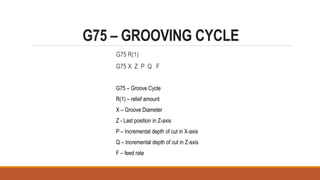

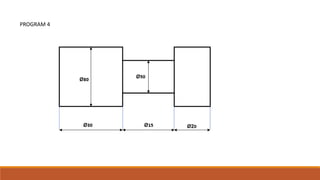

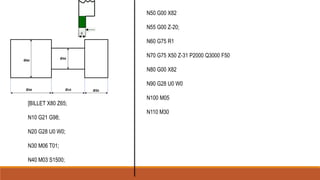

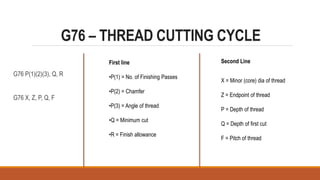

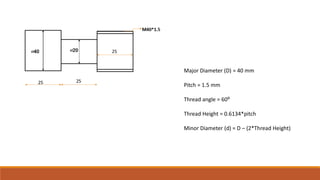

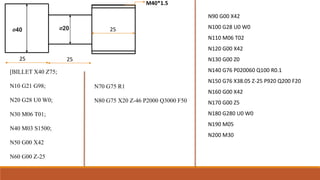

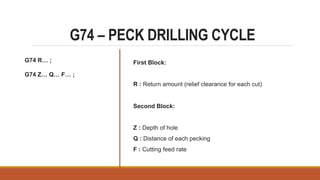

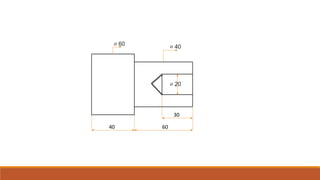

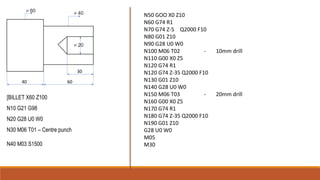

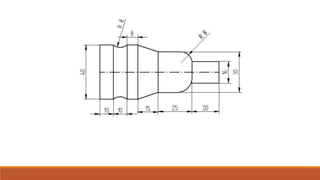

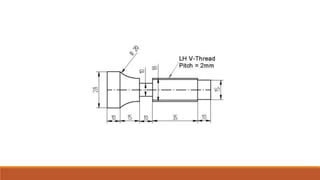

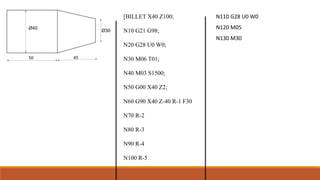

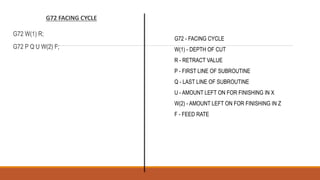

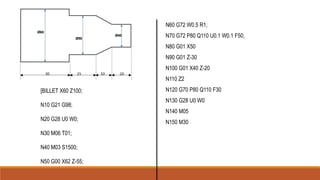

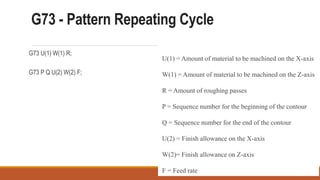

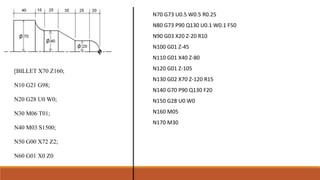

The document discusses CNC programming for both lathe and milling machines. It provides definitions and examples of common G-codes and M-codes used to control machine movements and auxiliary functions. Specific cycles are described for turning, grooving, threading, drilling, facing, and pattern repeating operations.