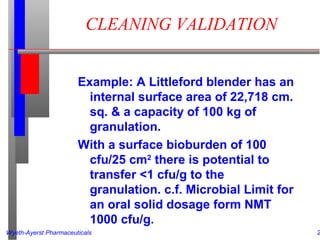

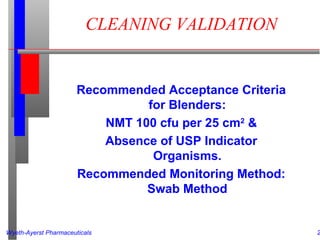

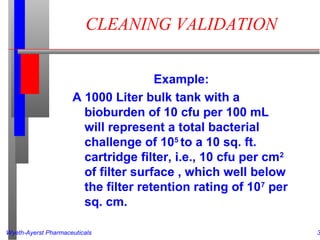

This document discusses current Good Manufacturing Practices requirements for cleaning validation according to the FDA. It provides an overview of microbial monitoring methods and their advantages and disadvantages. The document also provides examples of how to determine appropriate acceptance criteria for cleaning validation based on the equipment dimensions and volume of product being processed, to ensure the microbial limits for non-sterile and sterile products are met.