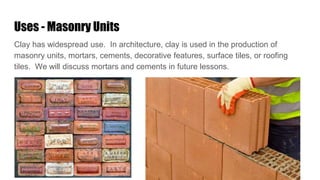

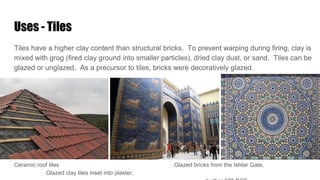

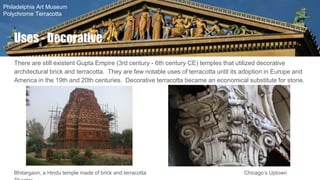

Clay is created through the decomposition of various rocks and minerals. It is structured with flat, disk-like particles that allow it to be molded when wet. Clay composition varies by source. Clay is used to make masonry units, tiles, and decorative architectural elements. Proper cleaning, identifying causes of deterioration, and using appropriate repair methods help preserve ceramic materials.