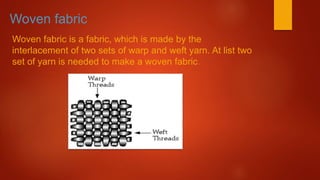

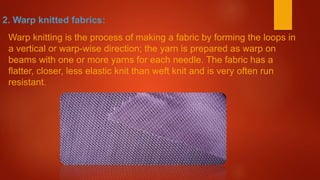

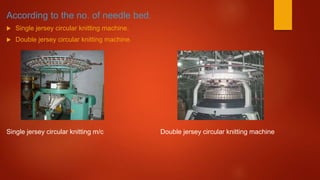

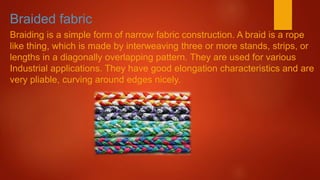

This presentation discusses the four main types of fabrics: woven, knitted, non-woven, and braided. Knitted fabrics are made by interlocking loops of yarn and can be weft or warp knitted. Common knit fabrics used in clothing include jersey, pique, and rib fabrics. Non-woven fabrics are made by bonding fibers together and are used in products like diapers, wipes, and filters. Braided fabrics are made by interweaving three or more yarns in an overlapping pattern and are used for applications requiring strength and flexibility.