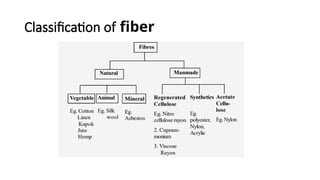

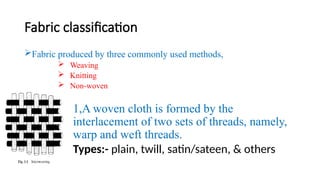

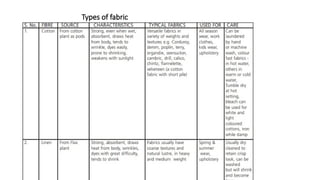

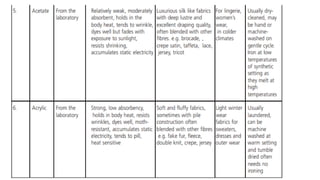

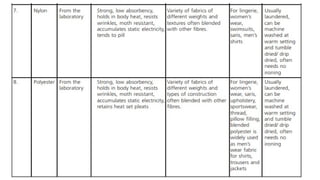

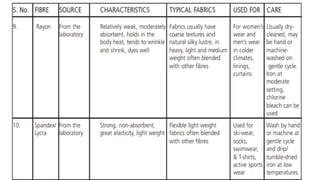

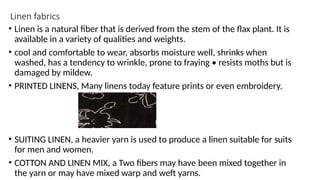

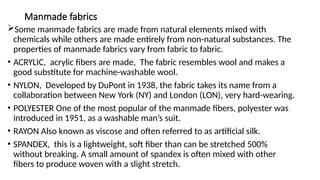

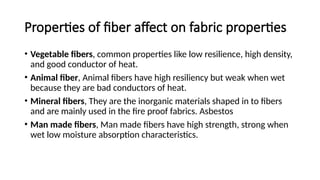

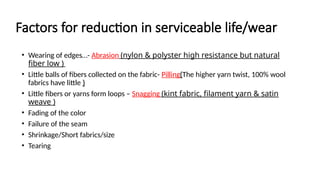

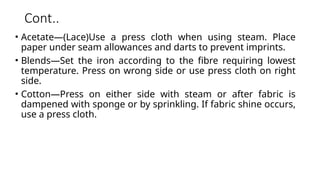

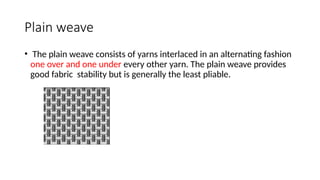

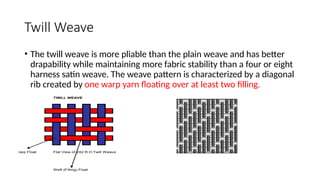

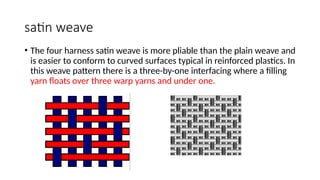

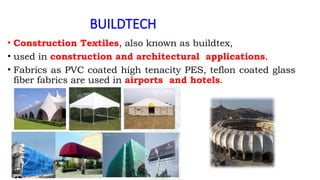

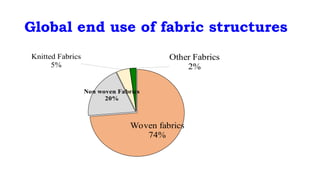

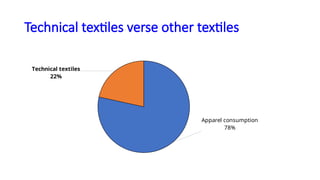

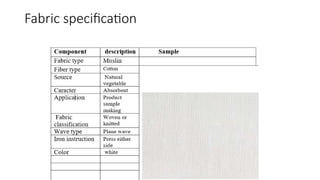

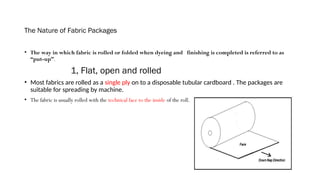

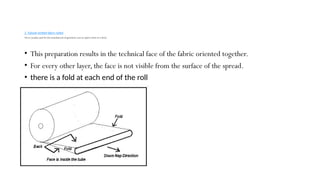

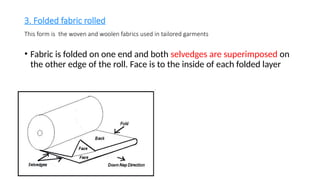

The document outlines a fabric study curriculum for first-year TVET garment students, focusing on fabric types, manufacturing processes, and properties of different fibers. It covers assessments, fabric classifications, the characteristics of various natural and man-made fibers, and the importance of fabric weave patterns. Additionally, it discusses the role of technical textiles, specification details, and the proper handling and pressing of fabrics.