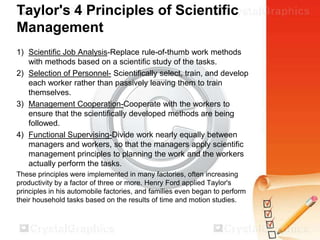

This document discusses classical organizational theory and scientific management. It provides background on Frederick Taylor's scientific management principles from the early 1900s, which aimed to optimize workflows. Taylor's four principles focused on finding the most efficient way to perform tasks, matching workers to jobs, close supervision, and using rewards/punishments. The document outlines various time and motion studies Taylor conducted to determine optimal work methods, and how these increased productivity but also led to more monotonous work. It provides context on the development of administrative theory and focus on classical organizational models like scientific management.