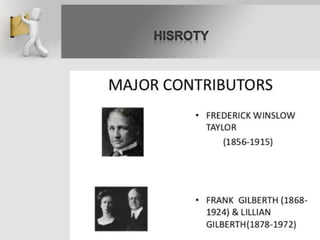

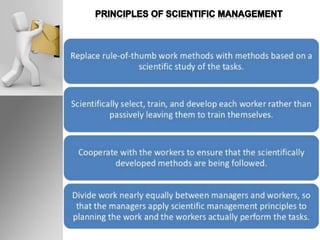

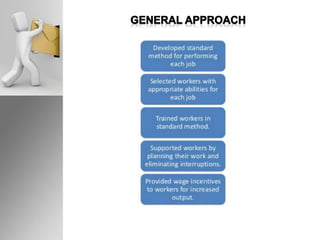

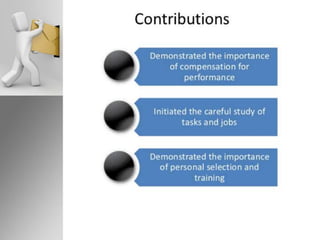

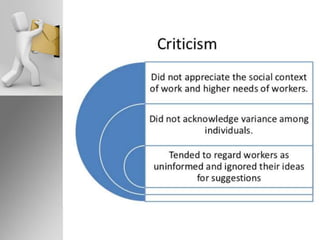

The document discusses Frederick Winslow Taylor and the principles of scientific management, including optimizing jobs to increase productivity, standardization of work processes, and cooperation between workers and managers. It provides an overview of Taylor's theories and principles, how scientific management was implemented, criticisms of the approach, and how some of its concepts are still used in modern management practices today. The presentation is made by several students who each cover different aspects of Taylor's scientific management and its applications.