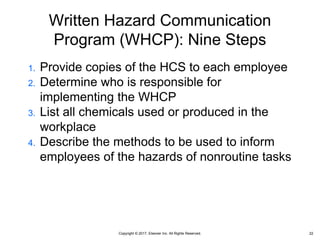

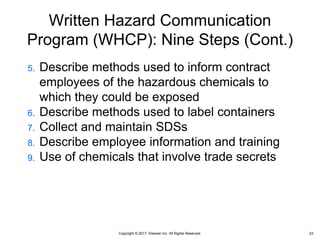

This document outlines the learning objectives and content for a lesson on managing chemicals safely. It discusses the goal of a hazard communication program which is to ensure employers and employees know about work hazards and how to protect themselves from chemical exposures. It describes the Occupational Safety and Health Administration's (OSHA) Hazard Communication Standard which requires employers to have a written hazard communication program, train employees on chemicals in the workplace, and maintain safety data sheets. The document discusses classifying chemical hazards, labeling containers, conducting an inventory of hazardous chemicals, and other components of an effective hazard communication program.

![Copyright © 2017, Elsevier Inc. All Rights Reserved.

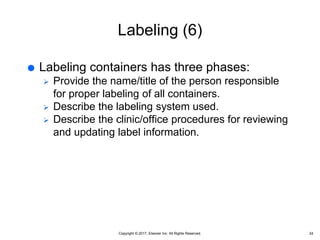

Labels and Other Forms of Warning

Some chemicals (especially dental materials

kits) are not labeled properly by their sources.

In such cases, the clinic/office must complete

the labeling process.

What should be included in the new

containers?

They must be labeled with

• [1] the identity of the hazardous chemical[s],

• [2] appropriate hazard warning, and

• [3] the name and address of the chemical manufacturer,

importer, or responsible party.)

29](https://image.slidesharecdn.com/chapter27powerpoint-200707170705/85/Chapter-27-Managing-Chemicals-Safely-29-320.jpg)