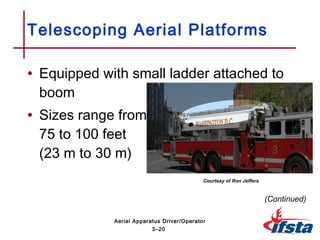

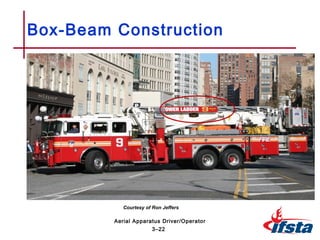

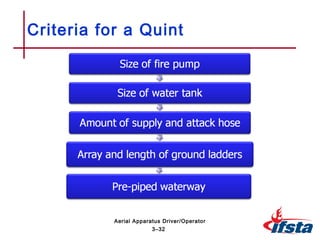

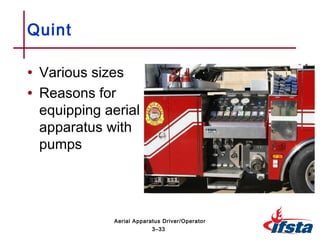

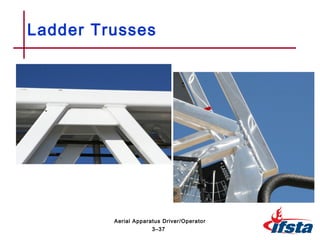

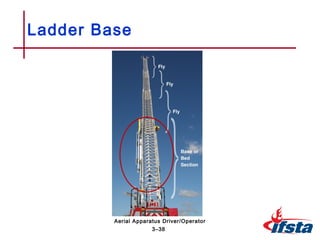

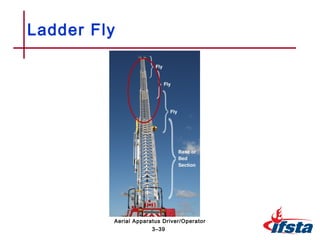

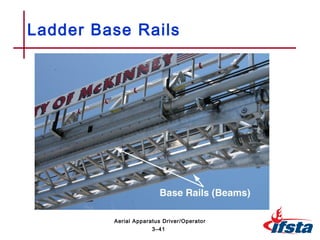

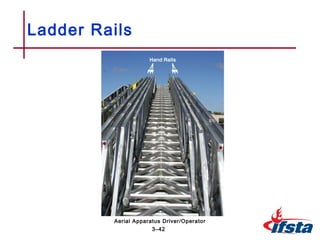

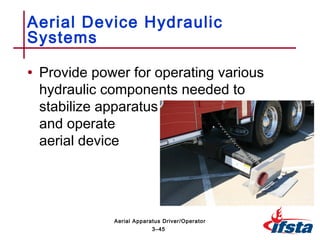

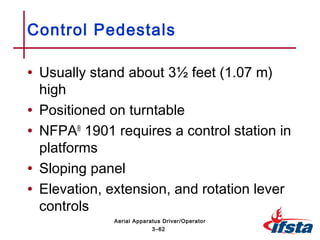

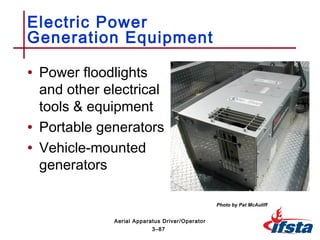

This chapter describes different types of aerial apparatus including aerial ladder trucks, elevating platforms, telescoping aerial platforms, articulating aerial platforms, water towers, and quintuple fire apparatus. It discusses the primary features of aerial devices such as ladders, trusses, bases, flies, and hydraulic systems. It also covers cable systems, chains, slides, rollers, turntables, control pedestals, water delivery systems, communication systems, breathing air systems, and other special systems that can be included on aerial apparatus.

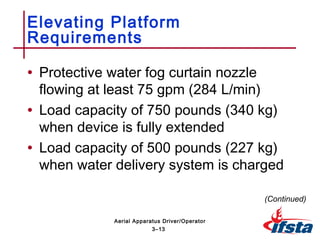

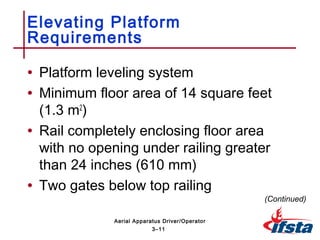

![• Kickplate at floor level (4 inches [100

mms] high)

• Drain openings

• Two operator control stations

• Backup hydraulic system

• Heat protective shield

Elevating Platform

Requirements

(Continued)

3–12

Aerial Apparatus Driver/Operator](https://image.slidesharecdn.com/chapter03-150307155154-conversion-gate01/85/Chapter-03-12-320.jpg)