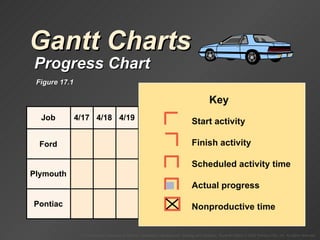

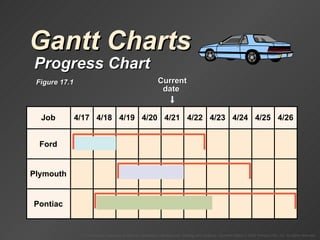

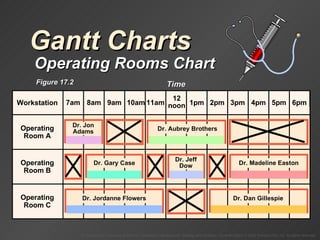

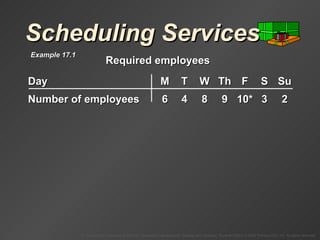

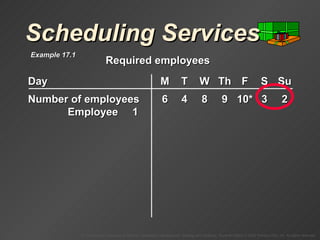

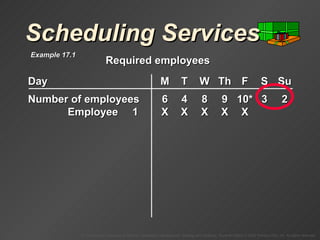

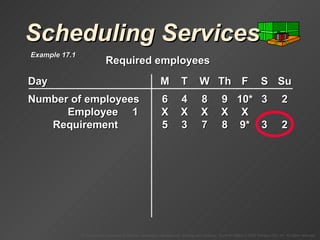

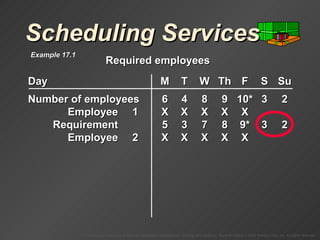

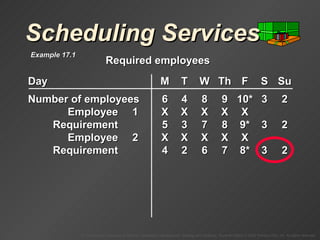

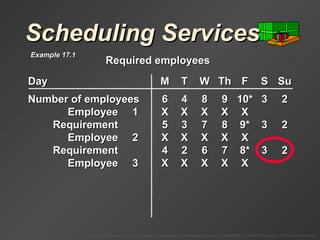

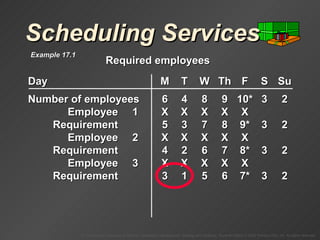

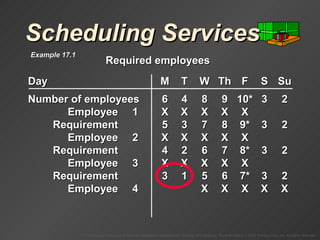

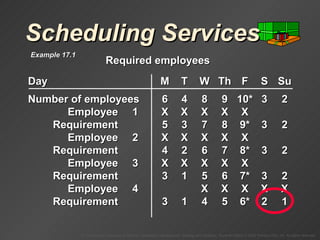

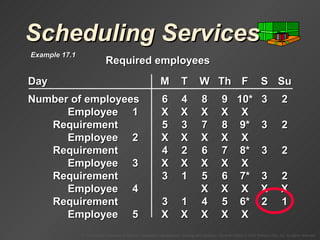

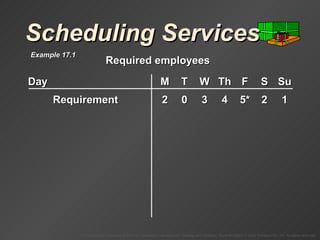

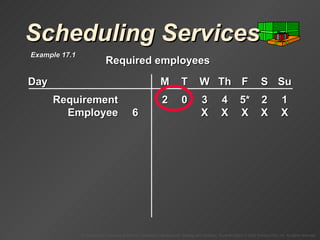

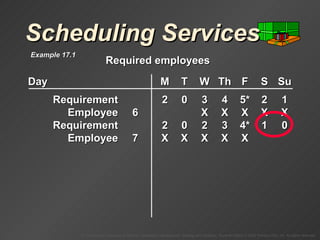

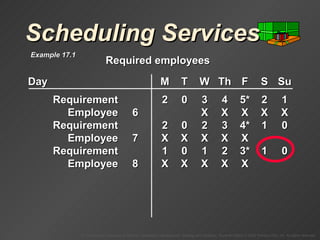

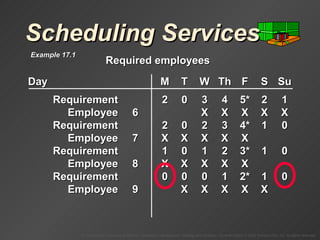

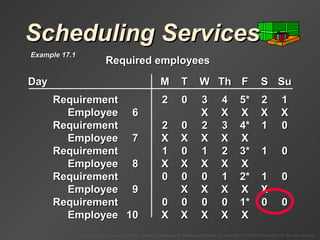

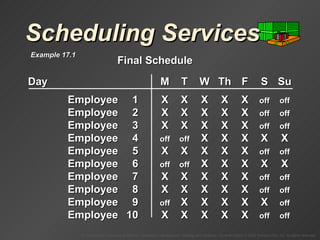

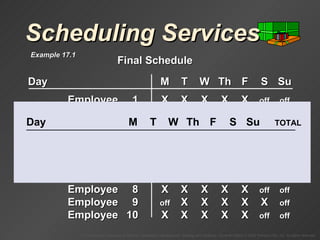

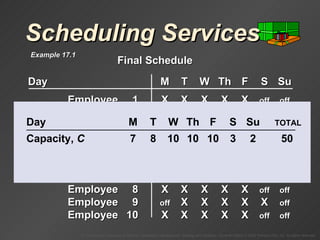

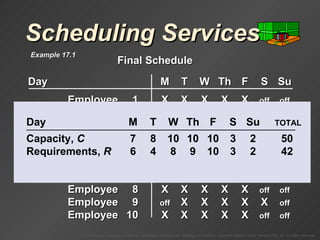

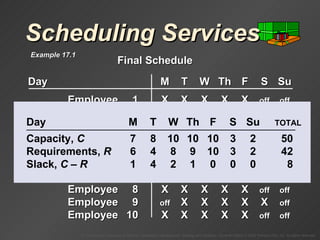

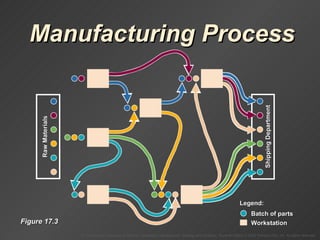

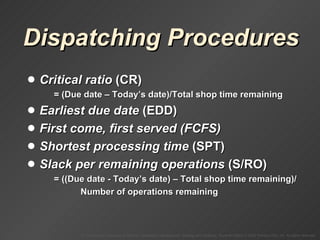

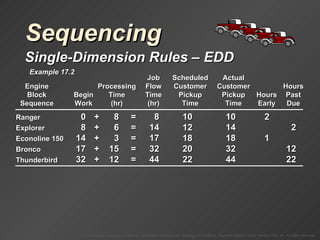

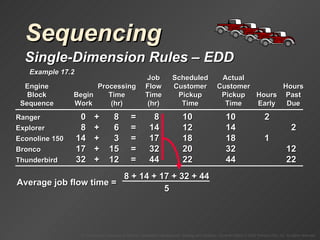

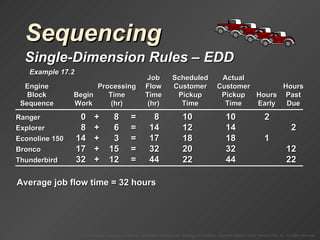

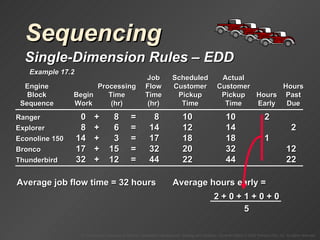

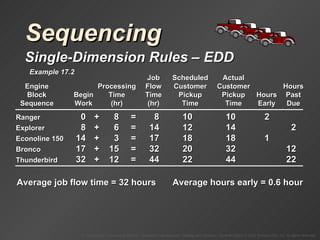

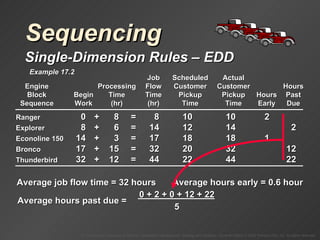

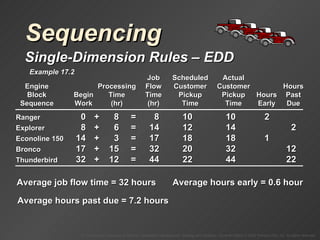

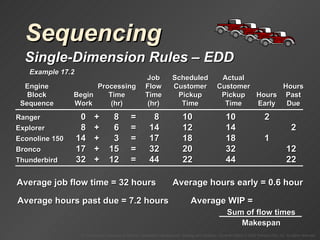

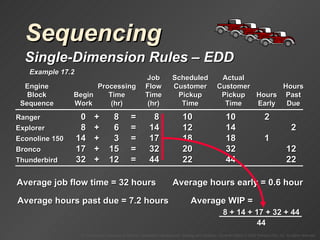

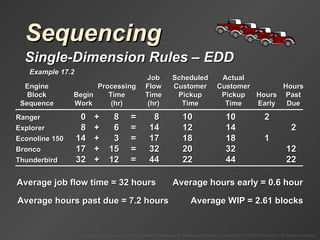

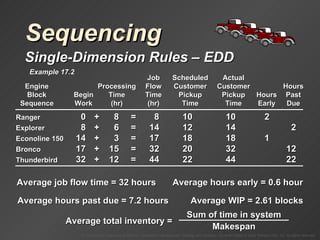

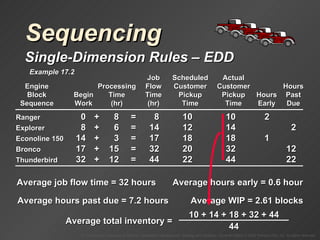

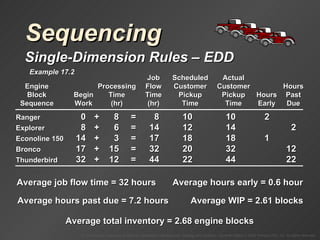

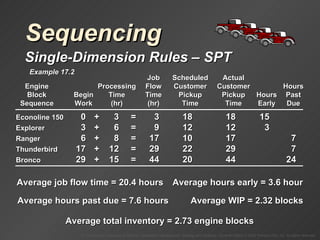

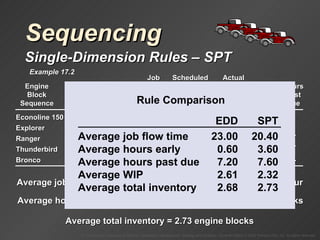

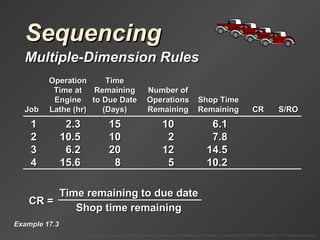

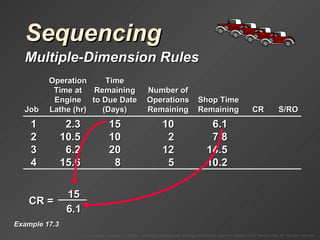

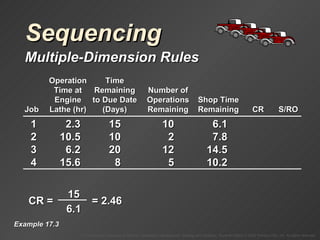

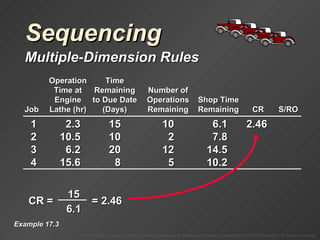

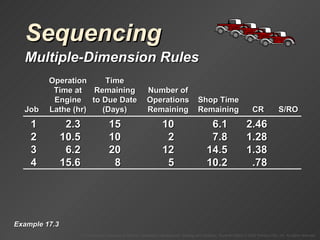

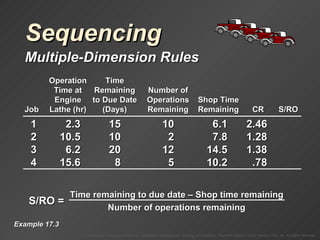

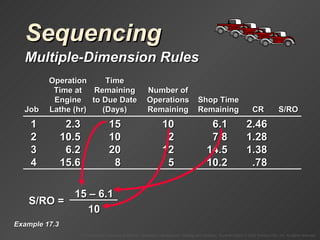

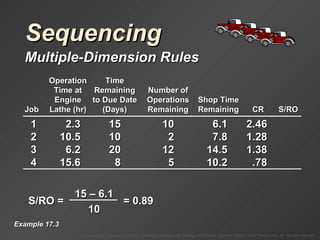

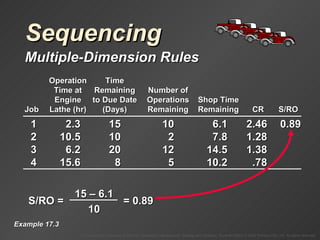

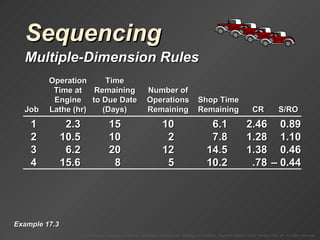

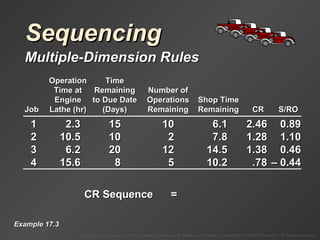

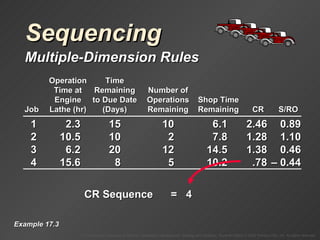

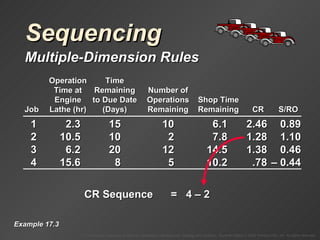

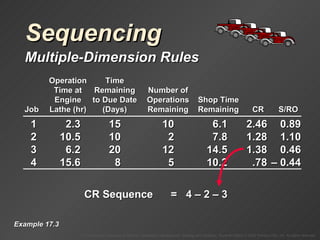

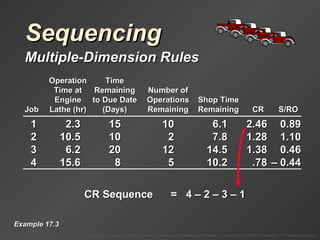

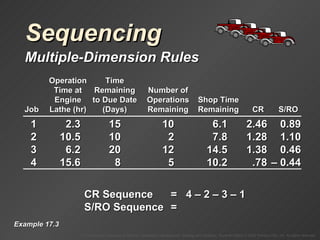

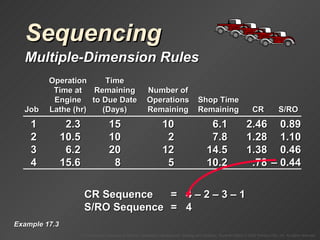

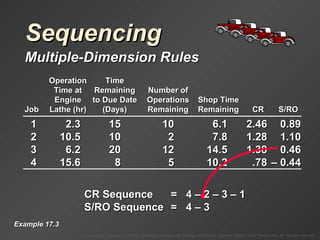

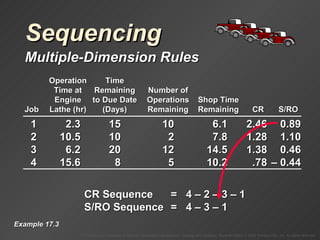

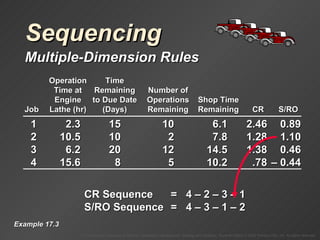

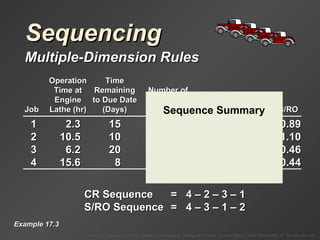

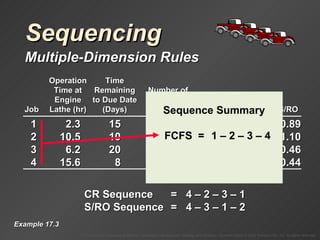

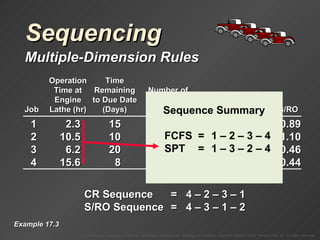

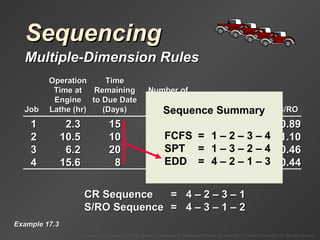

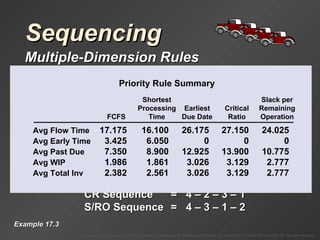

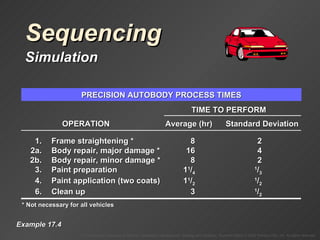

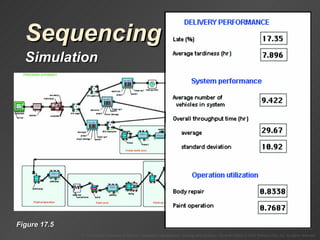

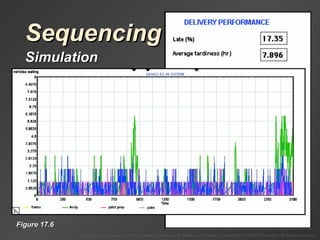

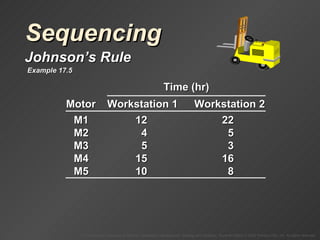

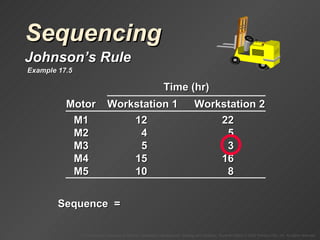

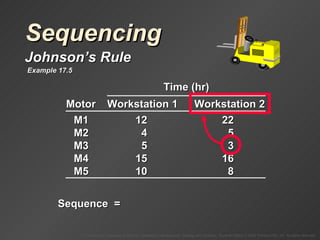

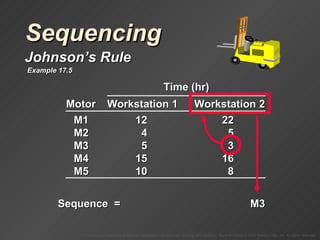

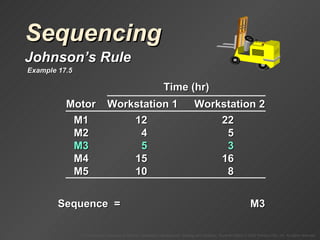

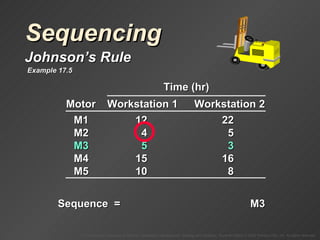

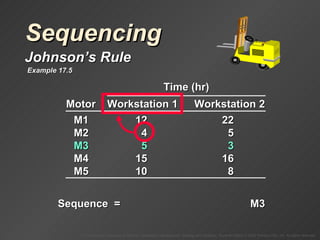

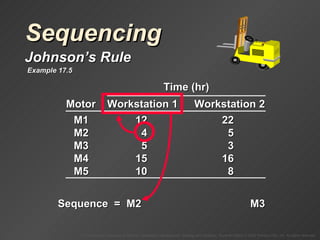

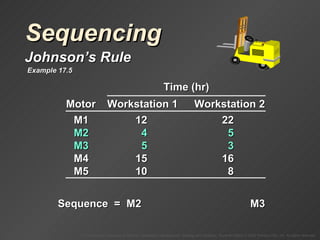

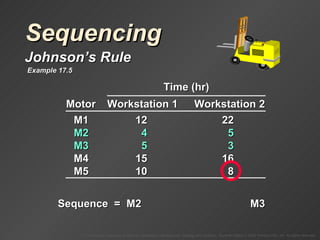

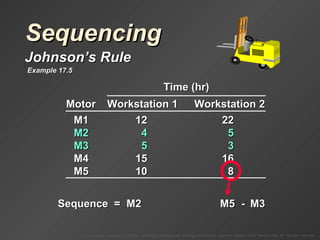

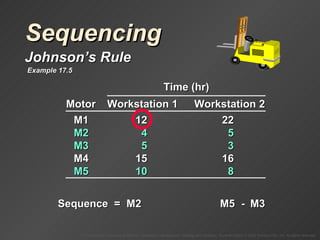

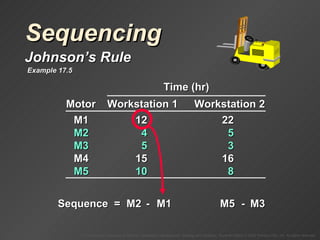

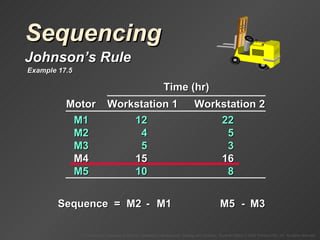

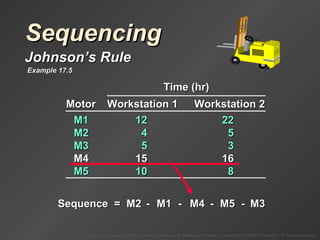

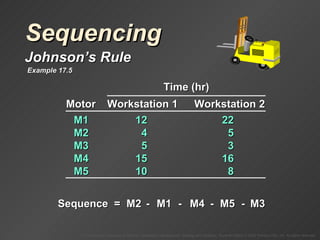

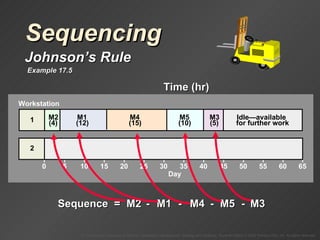

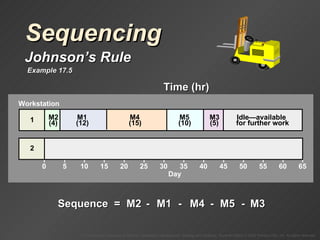

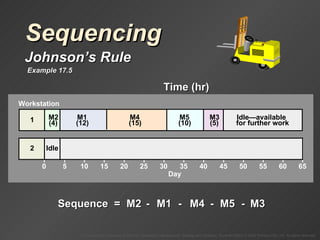

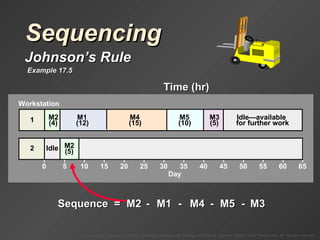

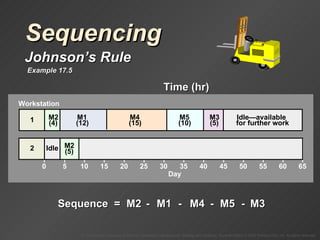

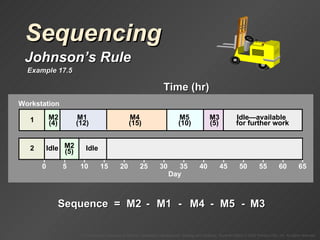

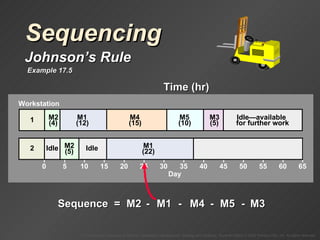

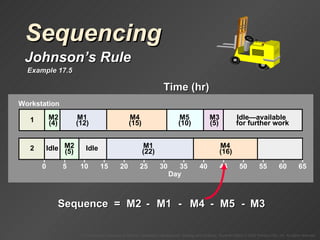

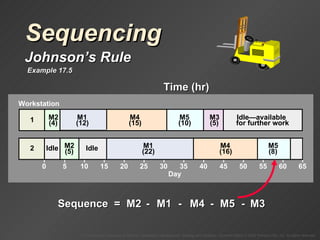

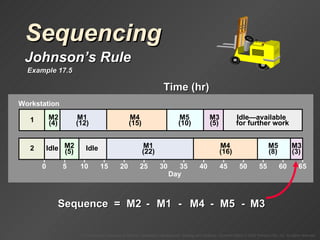

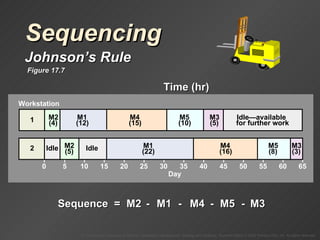

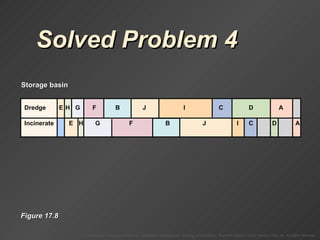

The document discusses scheduling and sequencing techniques using examples. It shows how to schedule employees to meet daily requirements using a Gantt chart. It also shows how to sequence jobs through a factory using single dimension rules like earliest due date, calculating metrics like average flow time, hours early/late and work in progress.