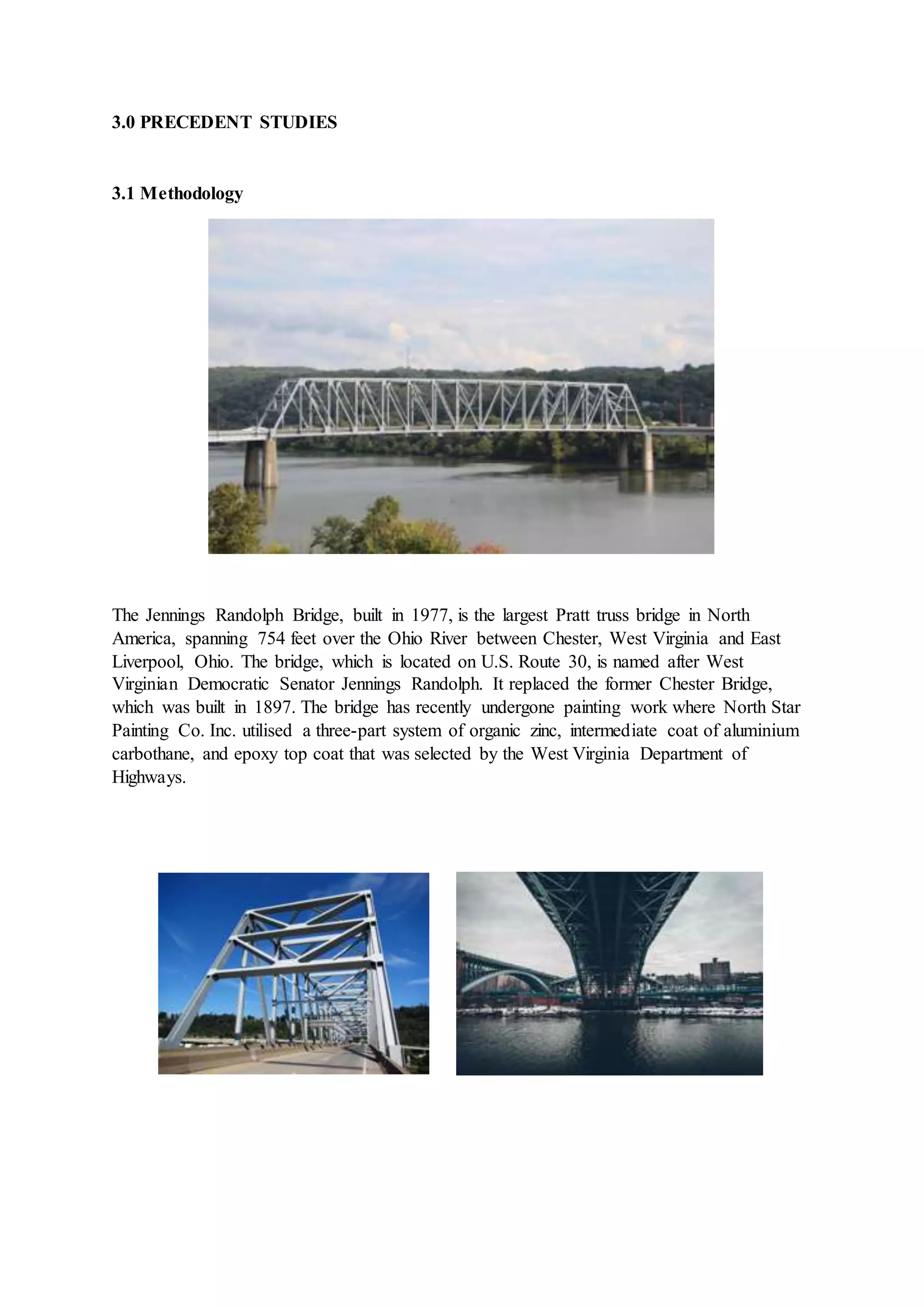

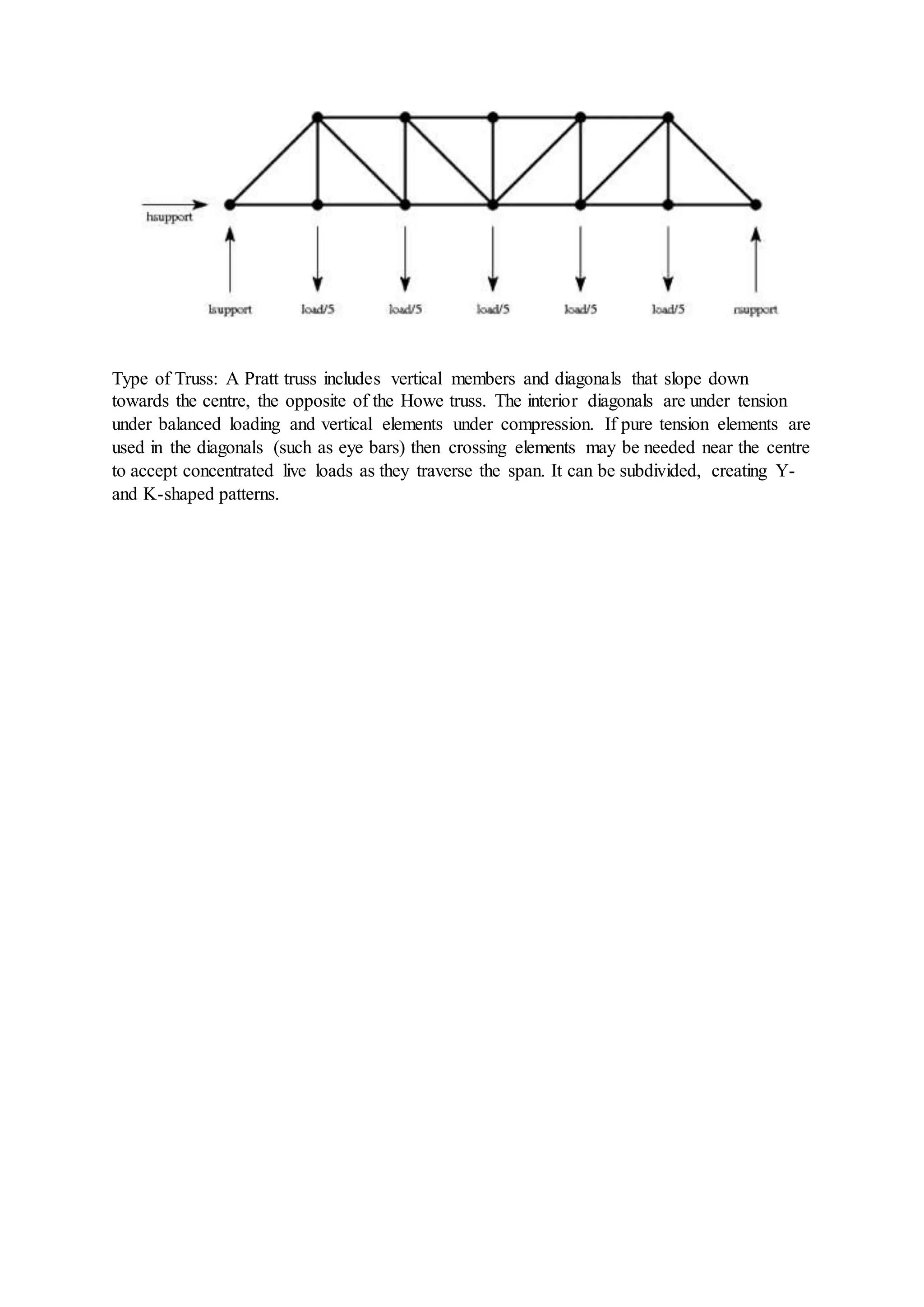

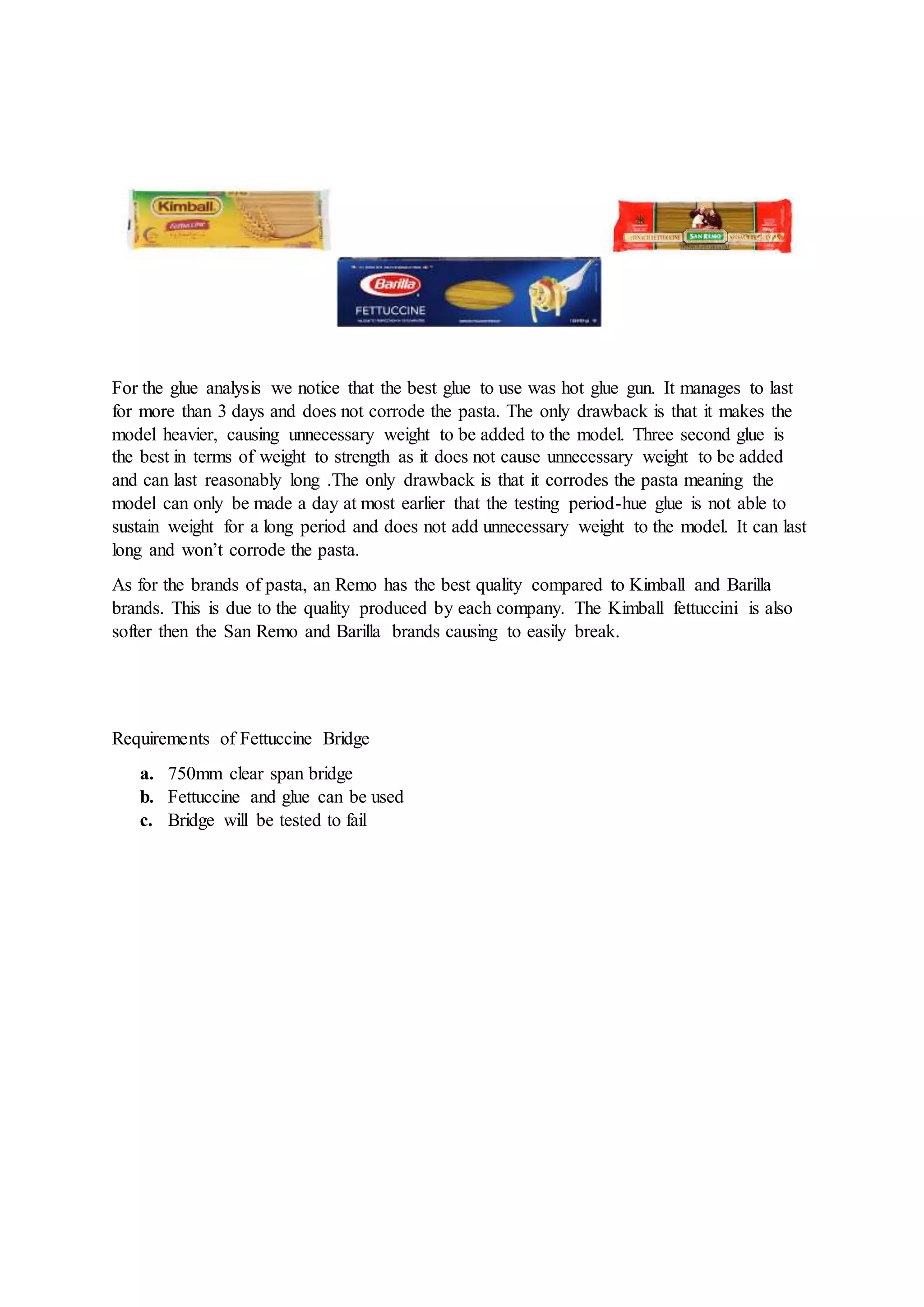

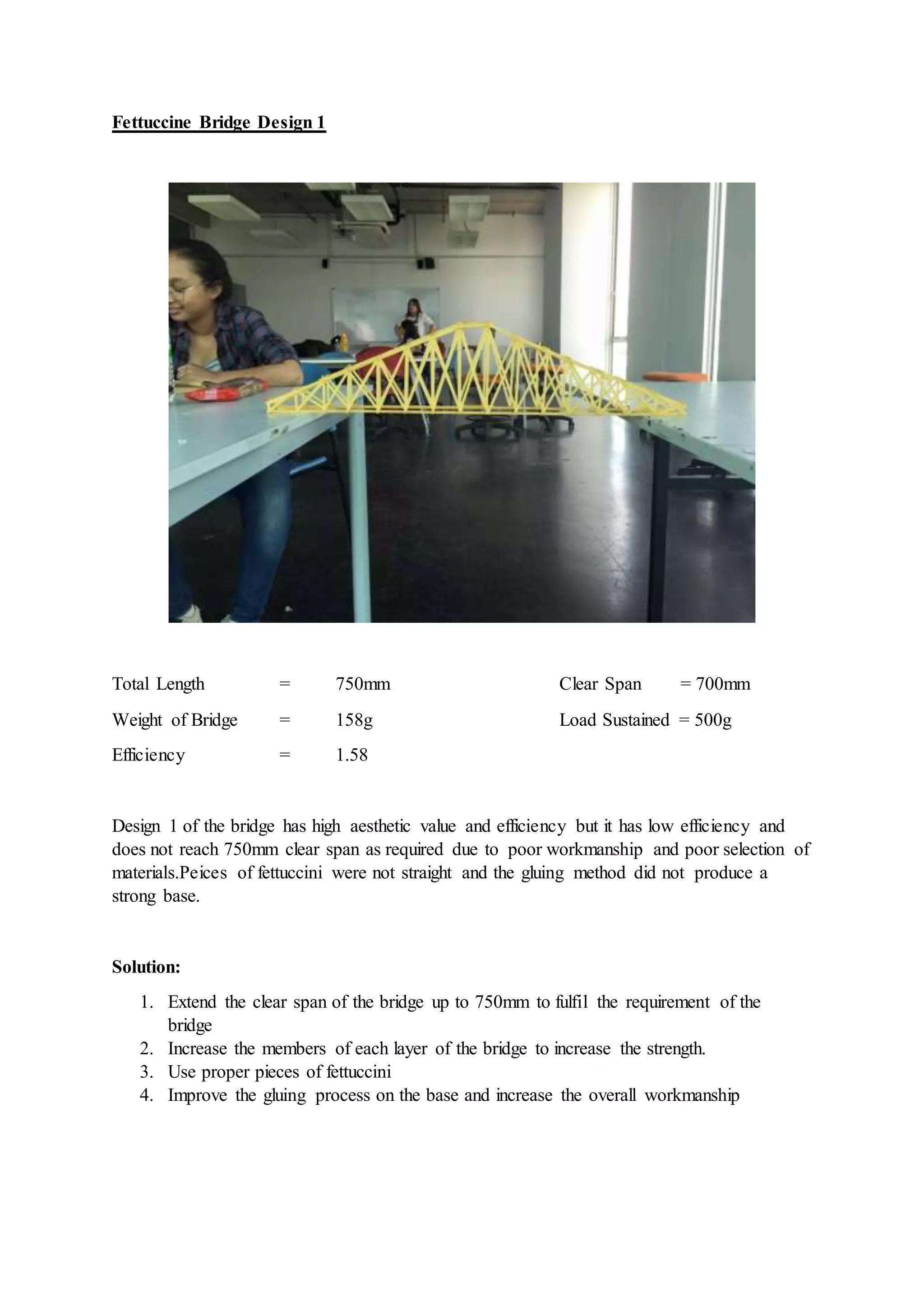

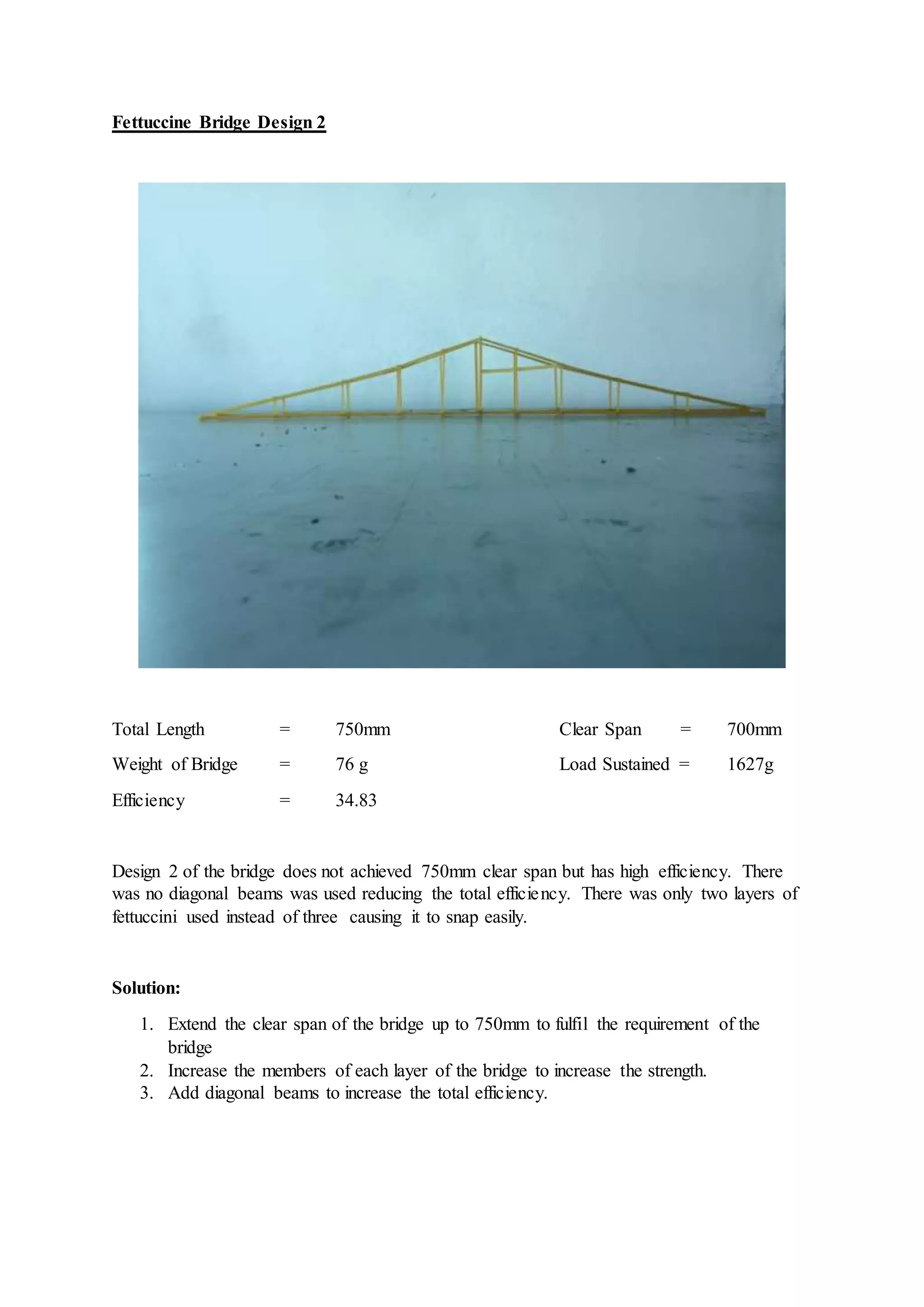

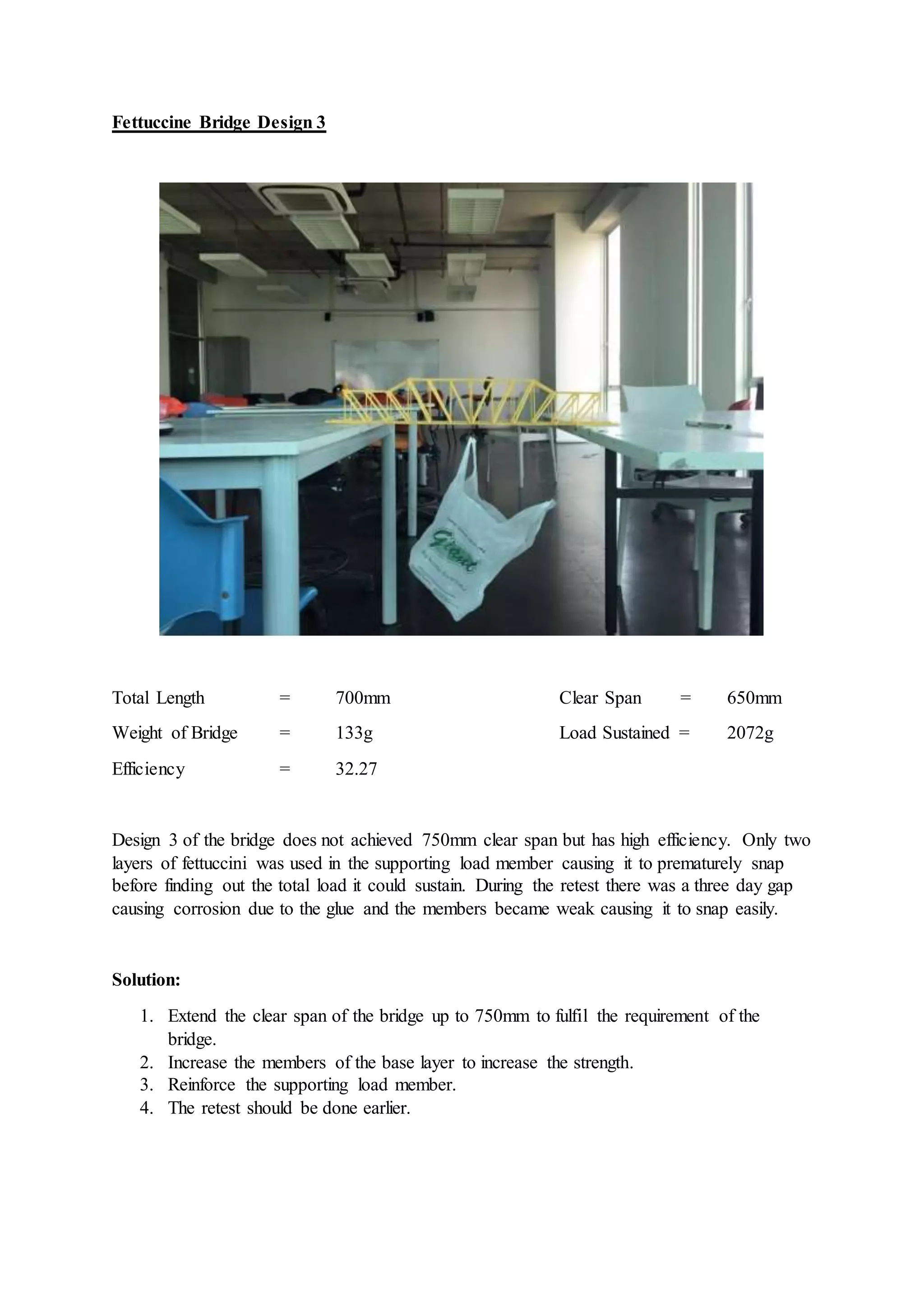

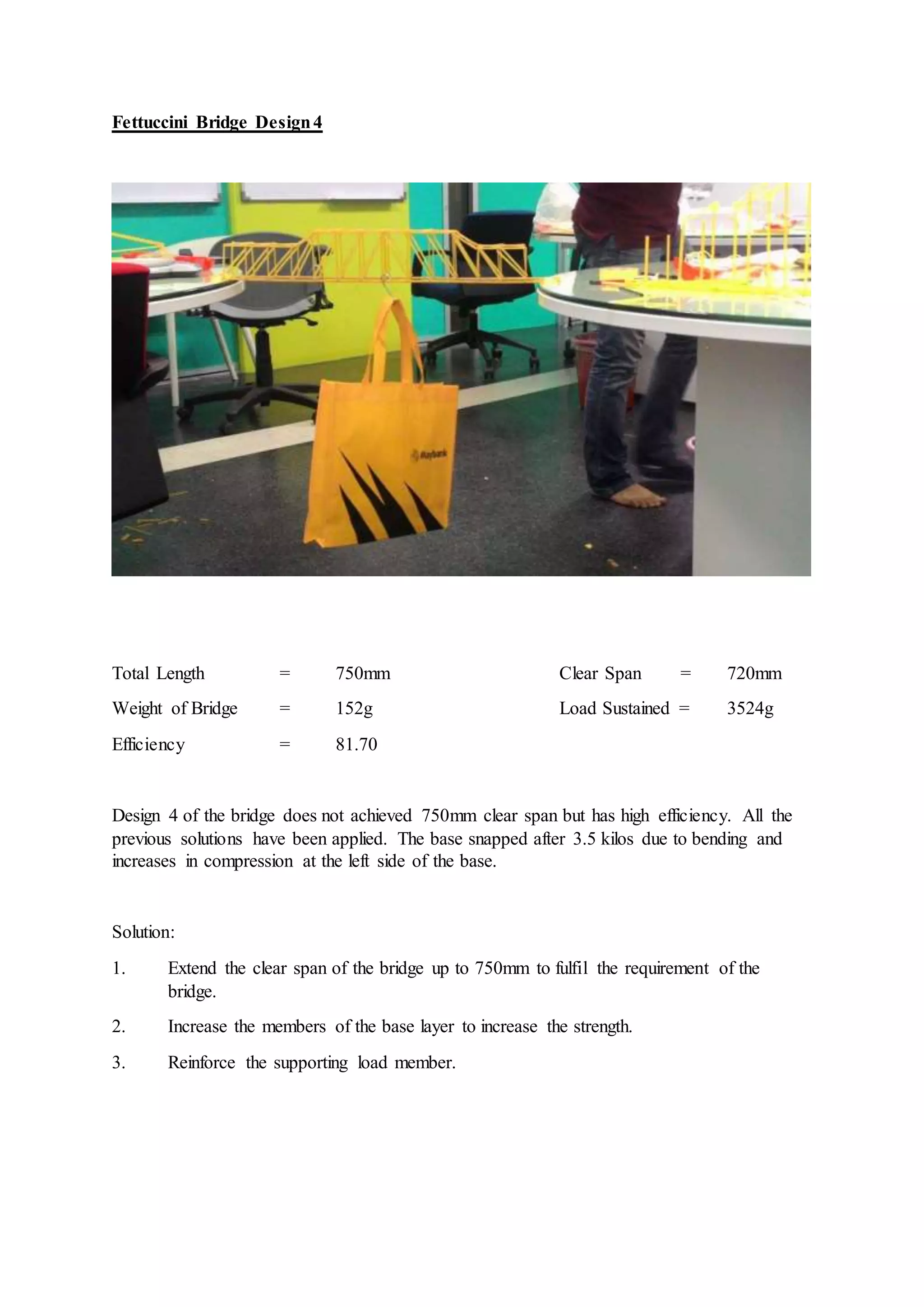

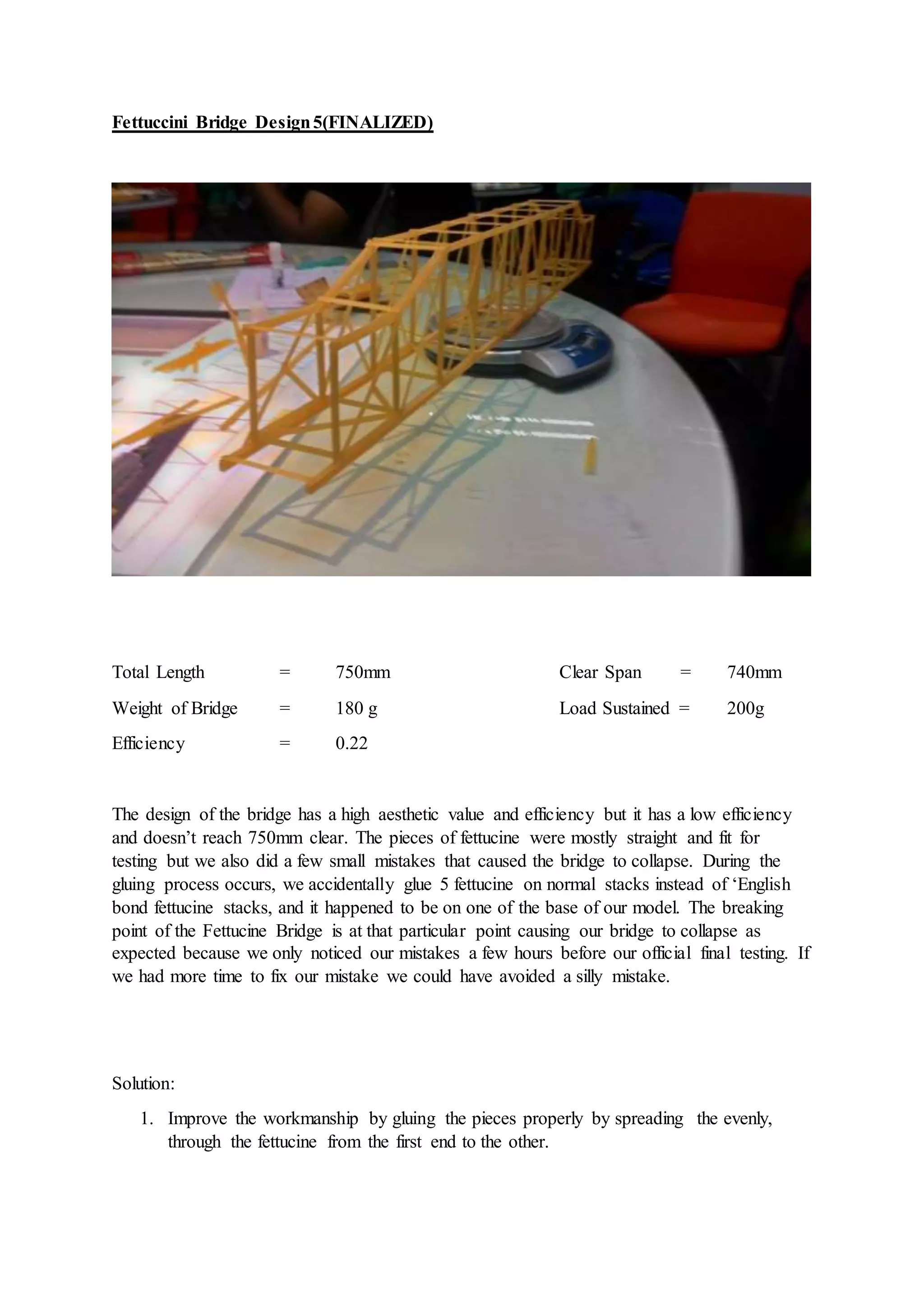

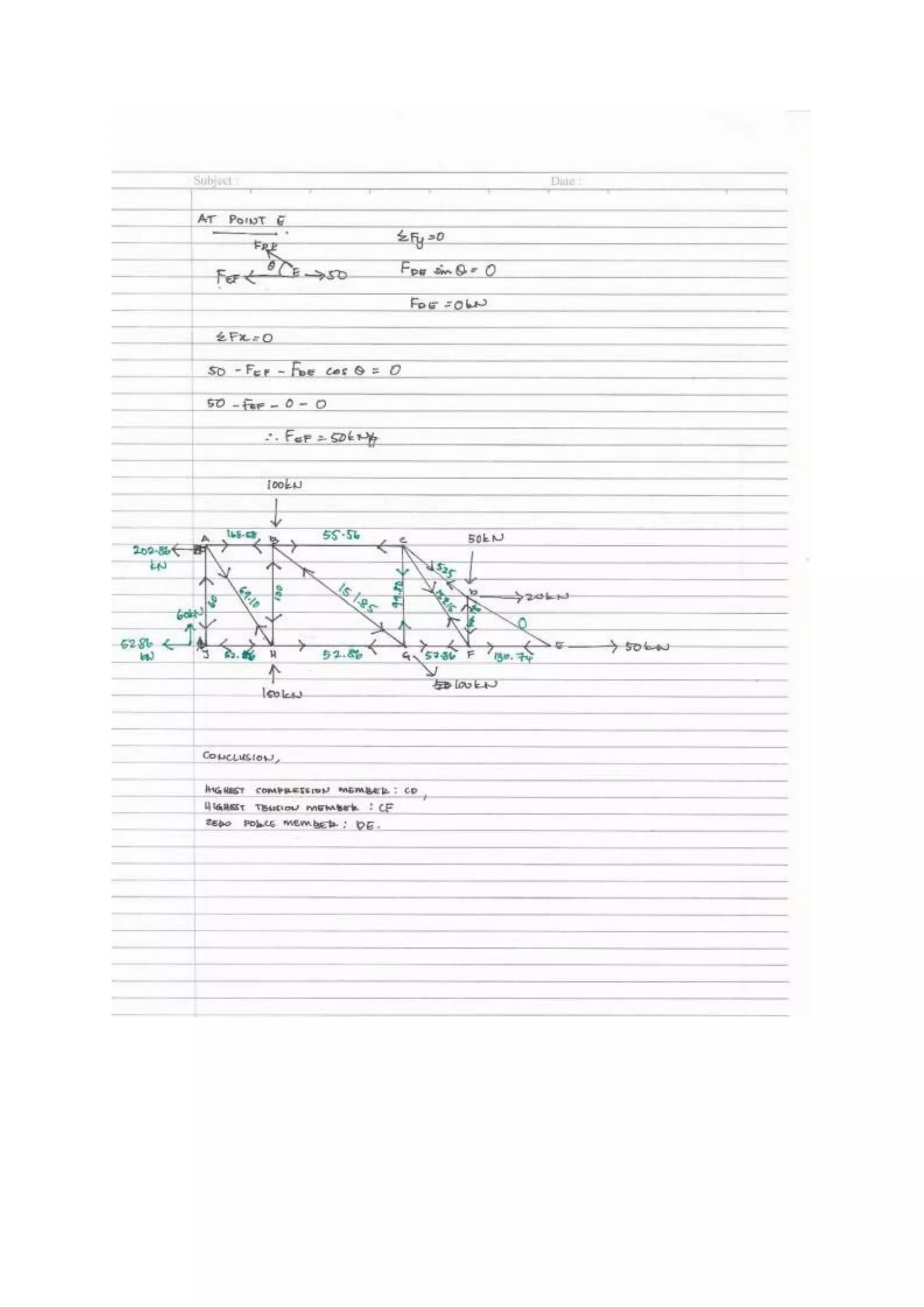

The document describes the design process of a fettuccine bridge that meets requirements of having a 750mm clear span, weighing less than 200g, and being made only of fettuccine and glue. Five bridge designs are presented with increasing spans and load capacities, but design flaws caused premature failures. The final design achieves a 740mm span but has low efficiency due to minor construction errors. Methodologies including material testing, structural analysis, and efficiency calculations are used to optimize the bridge design.