Cementing involves pumping cement slurry down the casing string to isolate formations and support the casing. Key steps include:

1. Pumping cement slurry down the casing string after displacing drilling mud with a spacer fluid.

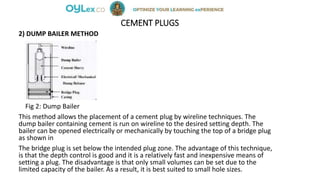

2. Releasing cement plugs to separate the cement from other fluids and indicate when cement displacement is complete.

3. Allowing the cement to set and harden before testing the zonal isolation provided by the cement sheath.

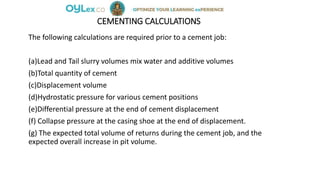

Proper additives, testing, calculations and centralization of the casing are important to achieve a good cement bond between the casing and formation.