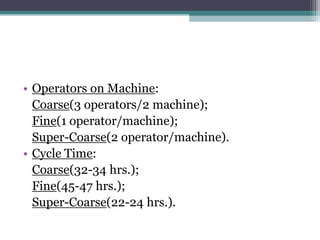

This document provides a summary of a project to identify ineffective time at an Indo Rama Synthetics polyester manufacturing plant. The objectives are to determine operator idle time, calculate standard cycle times, and suggest improvements. 49 draw texturized yarn machines will be studied using time and method study tools to rationalize times and improve productivity by reducing cycle times and operator idle time. Suggestions include using ear plugs due to noise levels and accurately recording times with stopwatches.