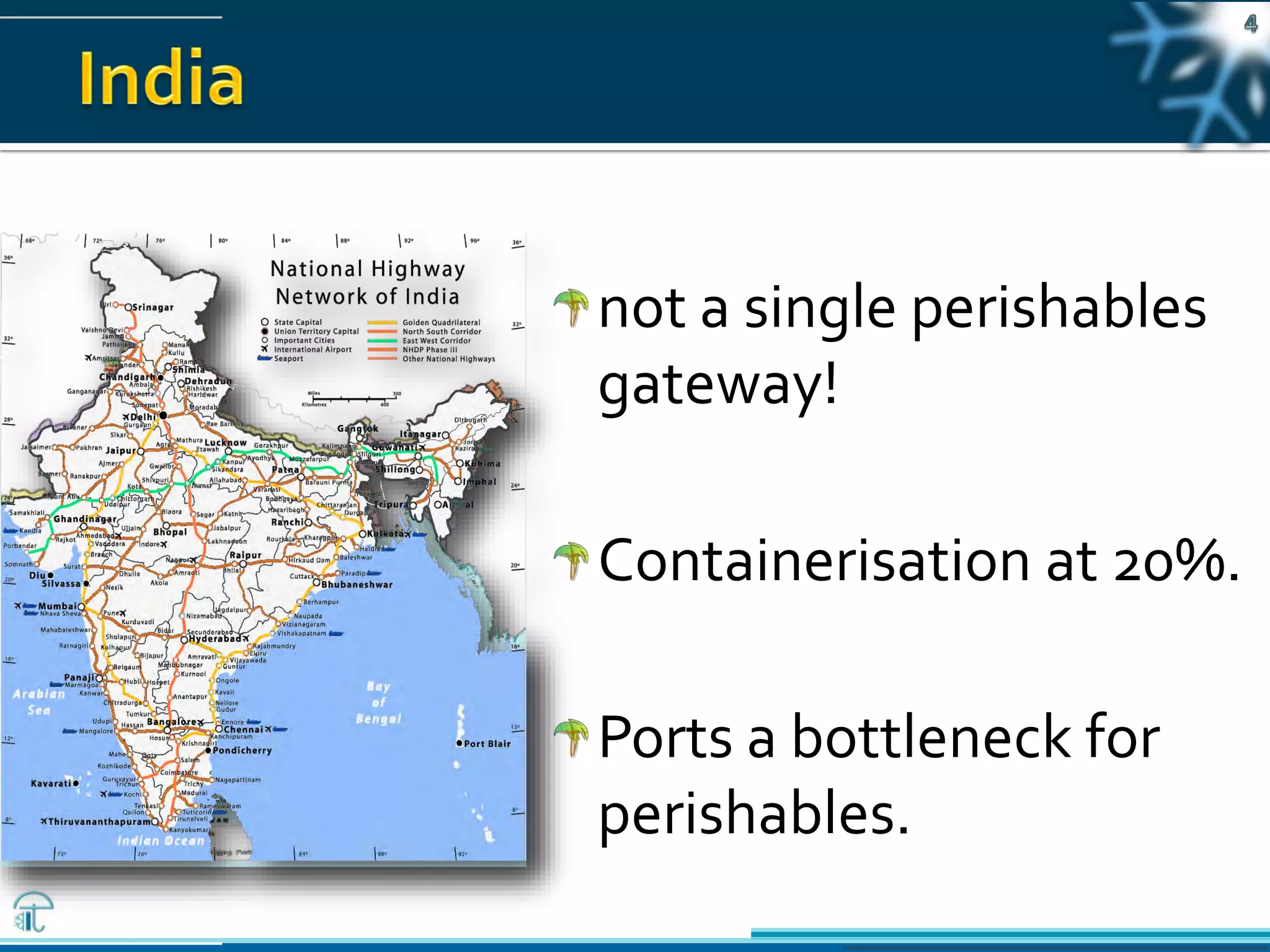

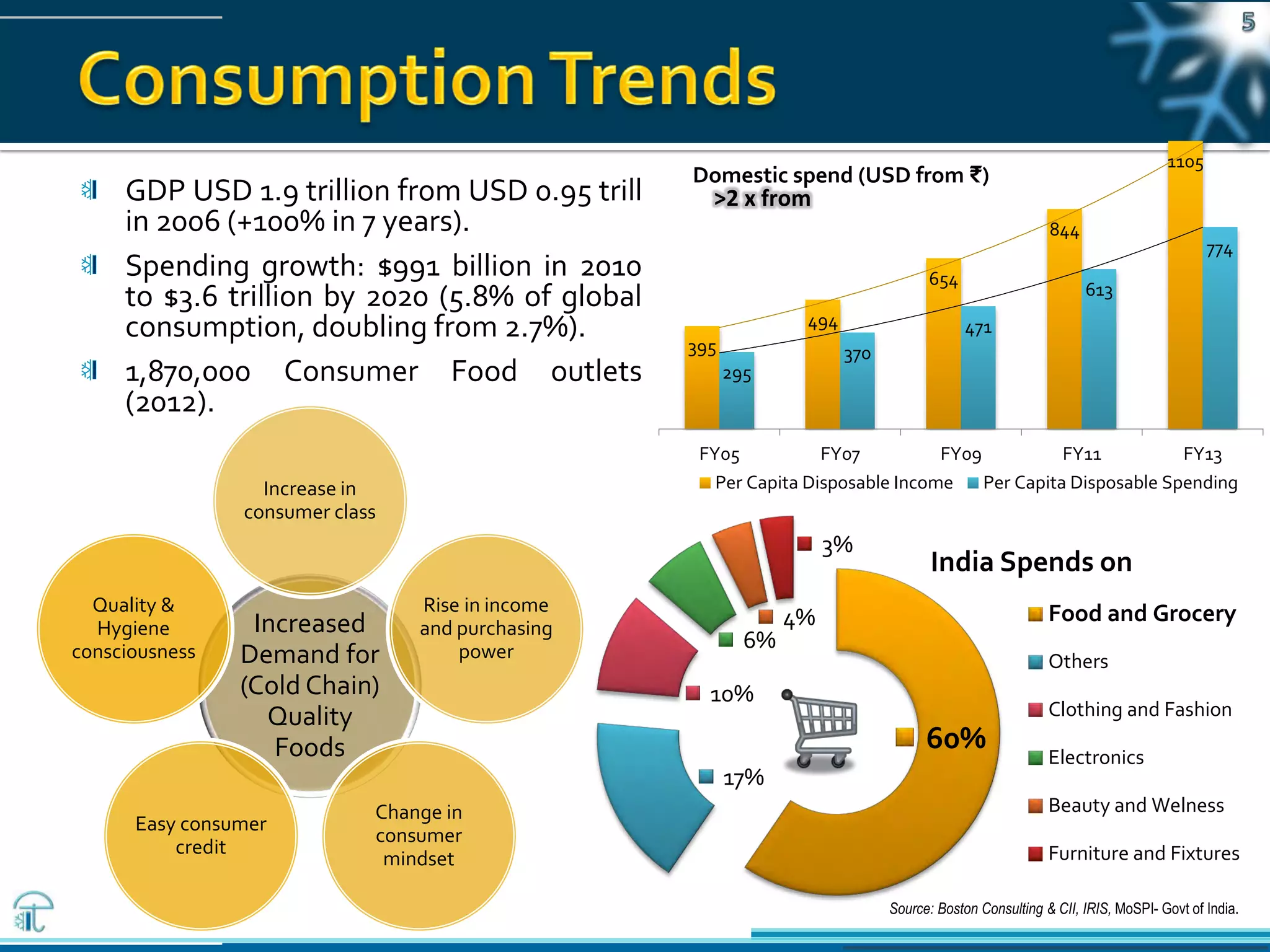

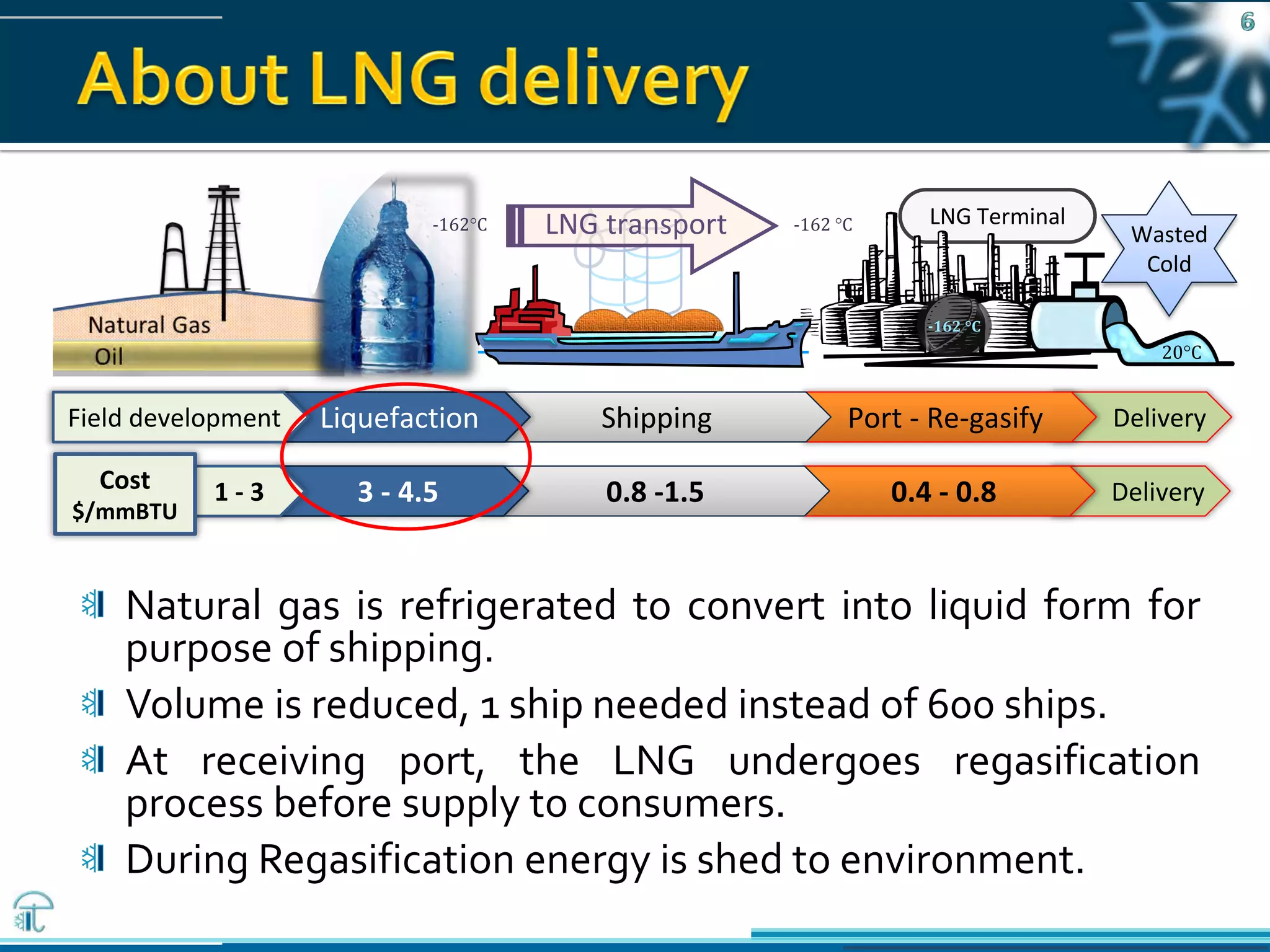

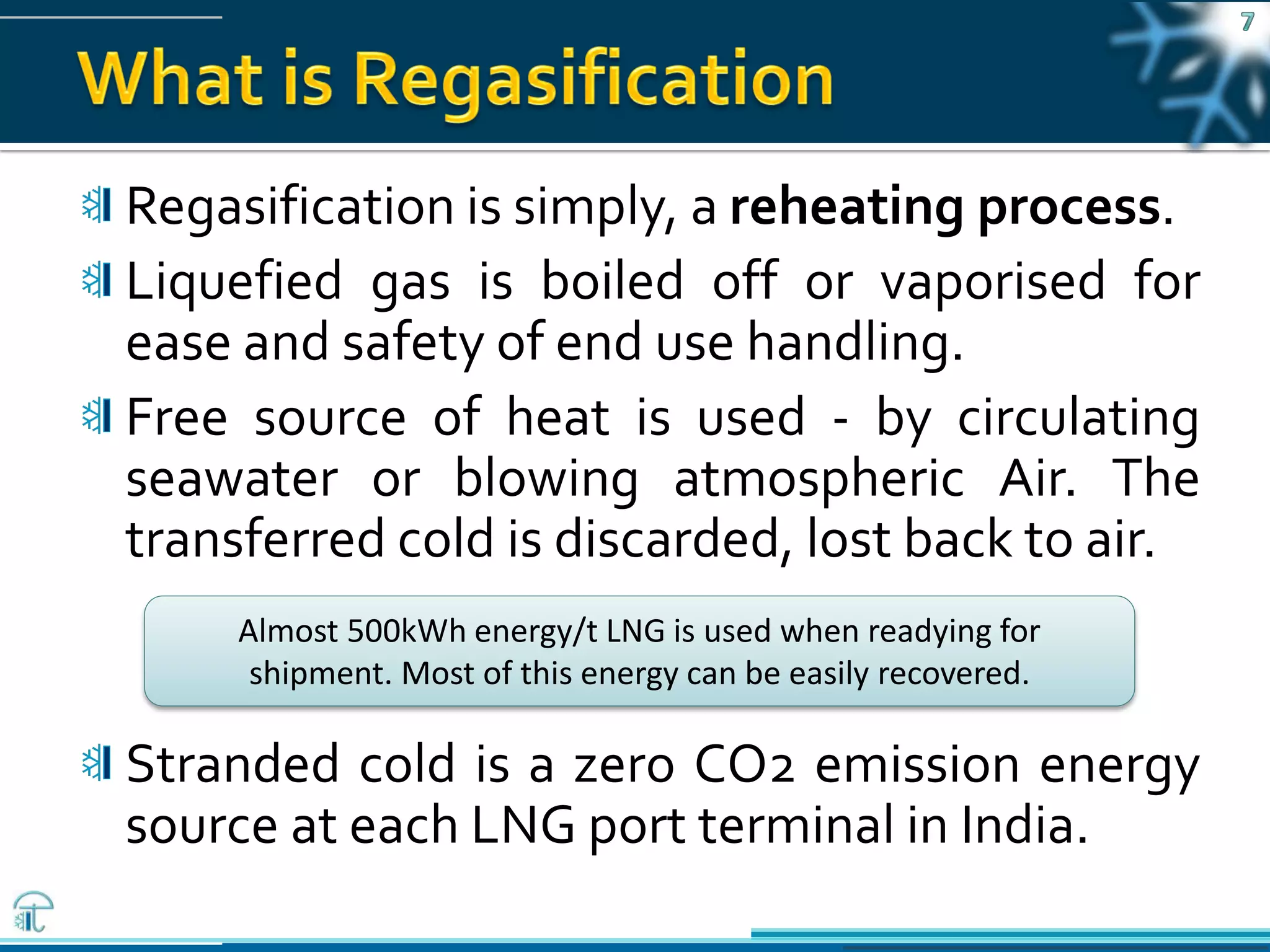

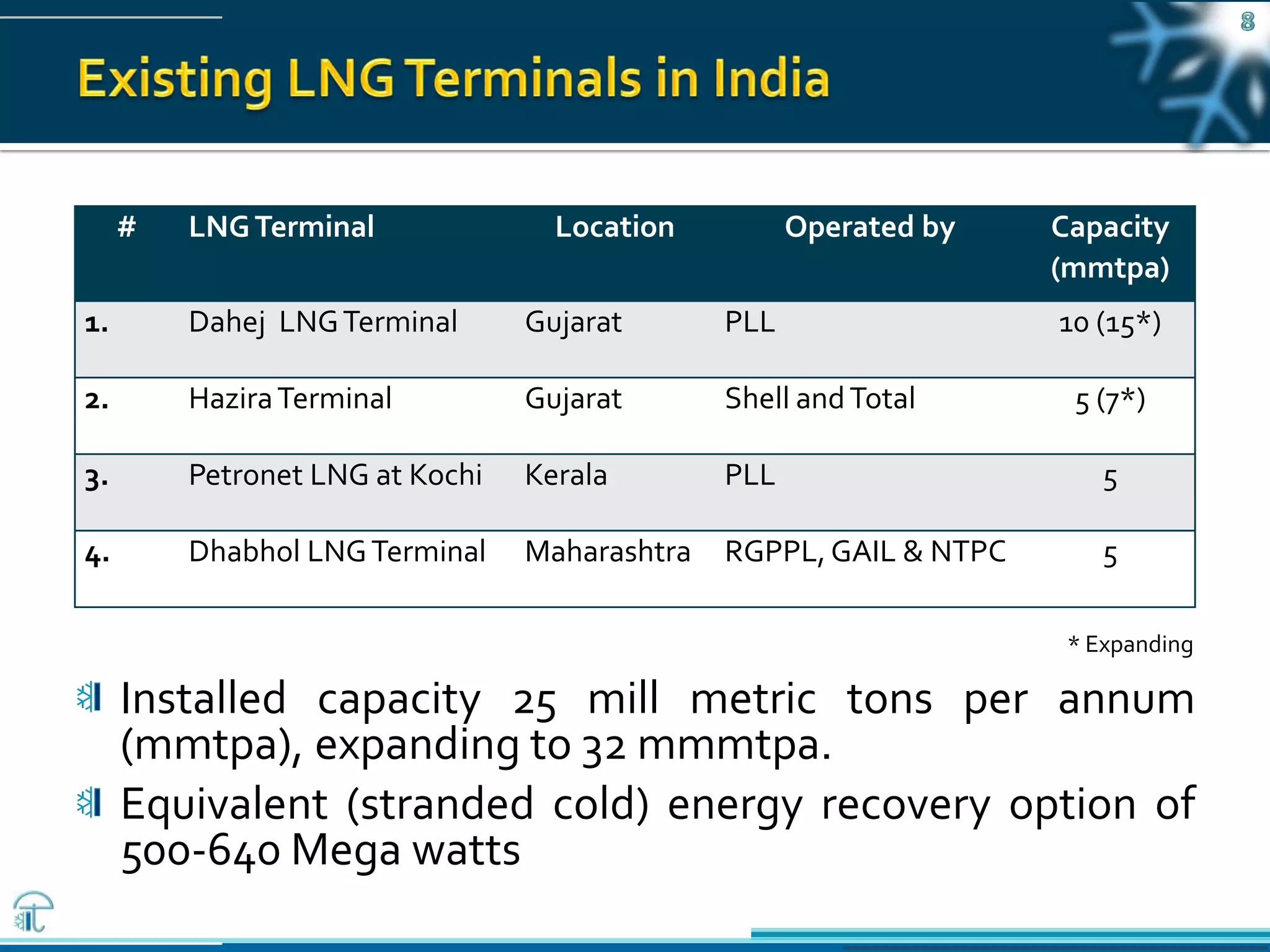

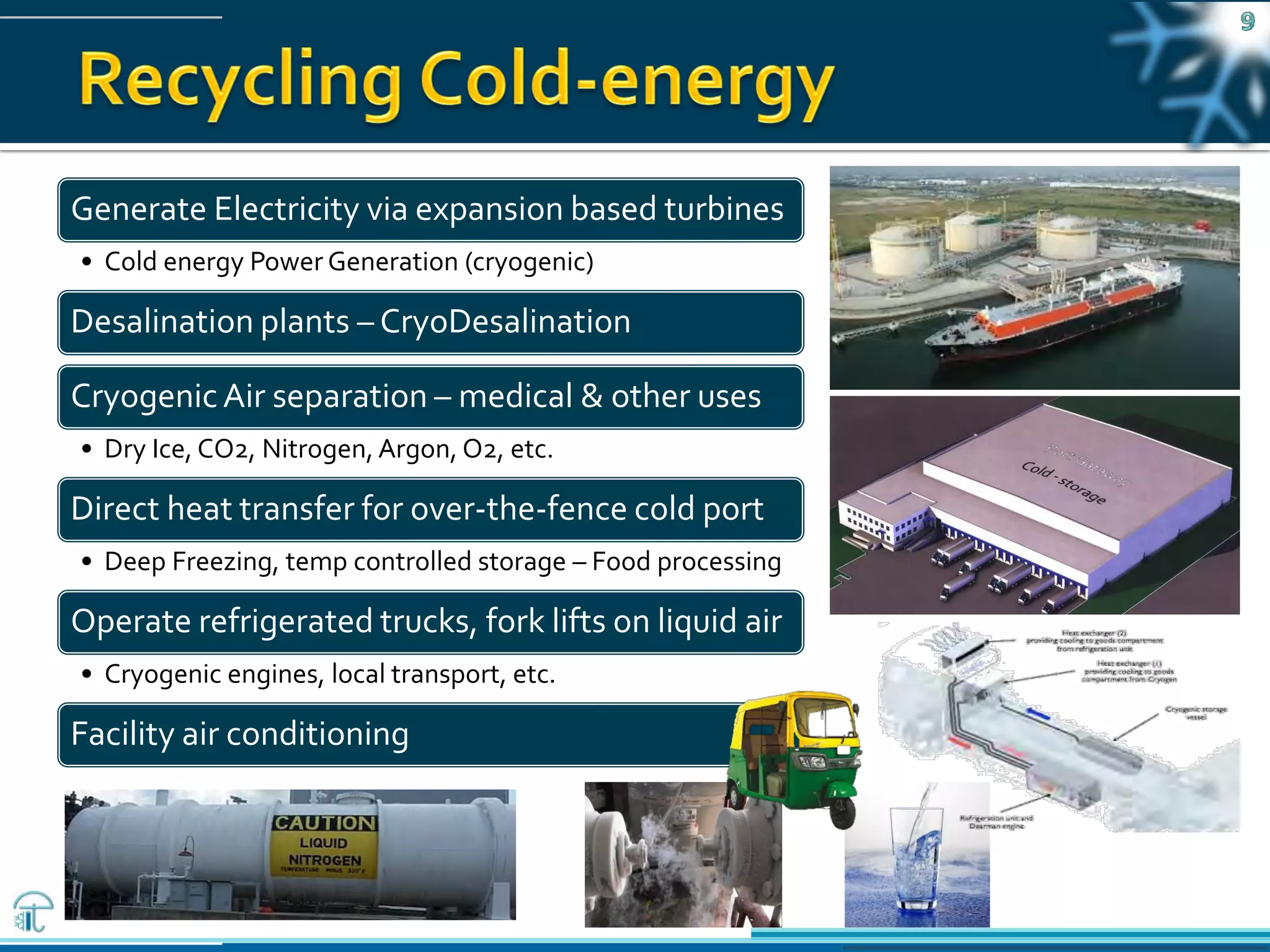

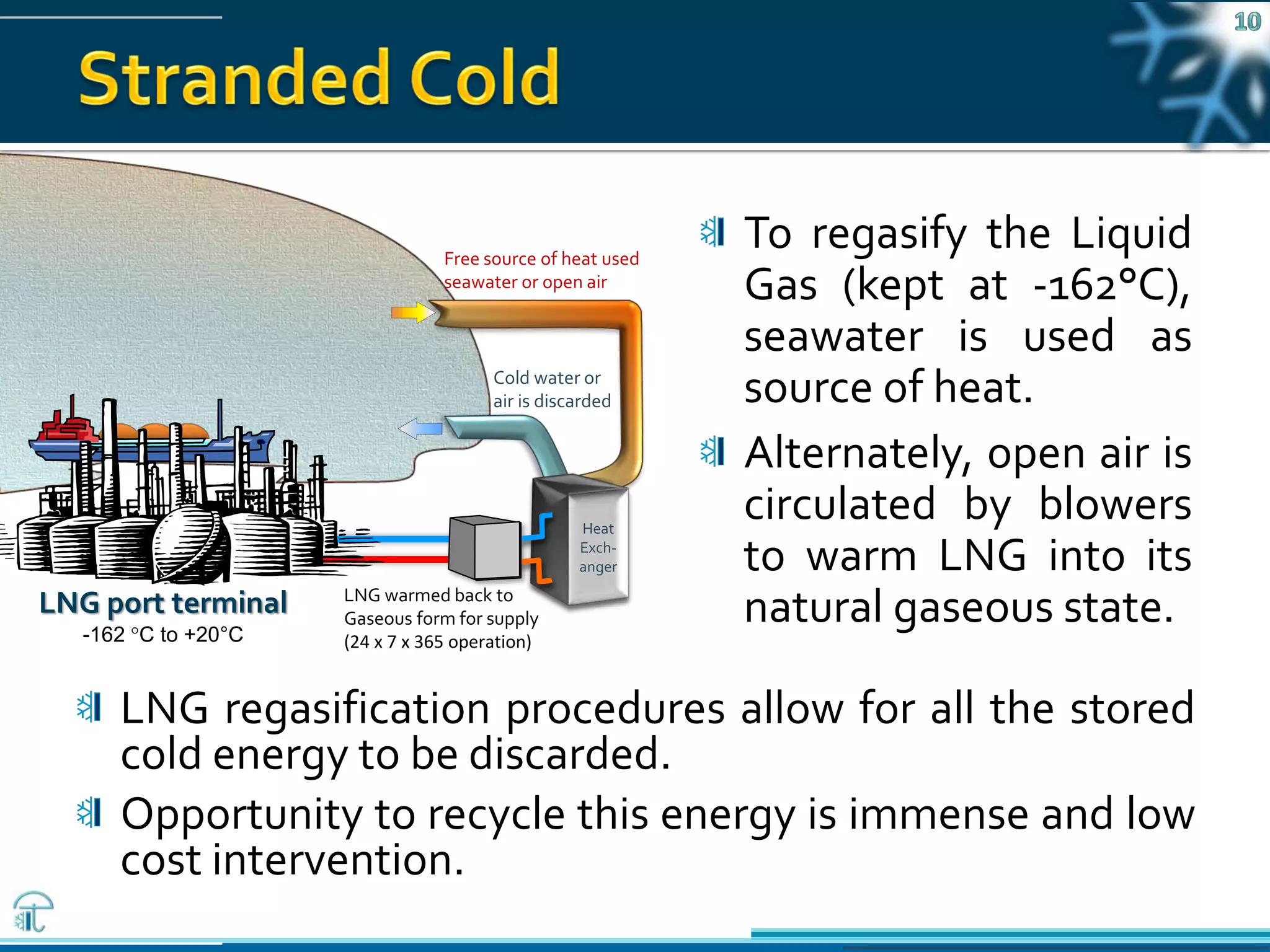

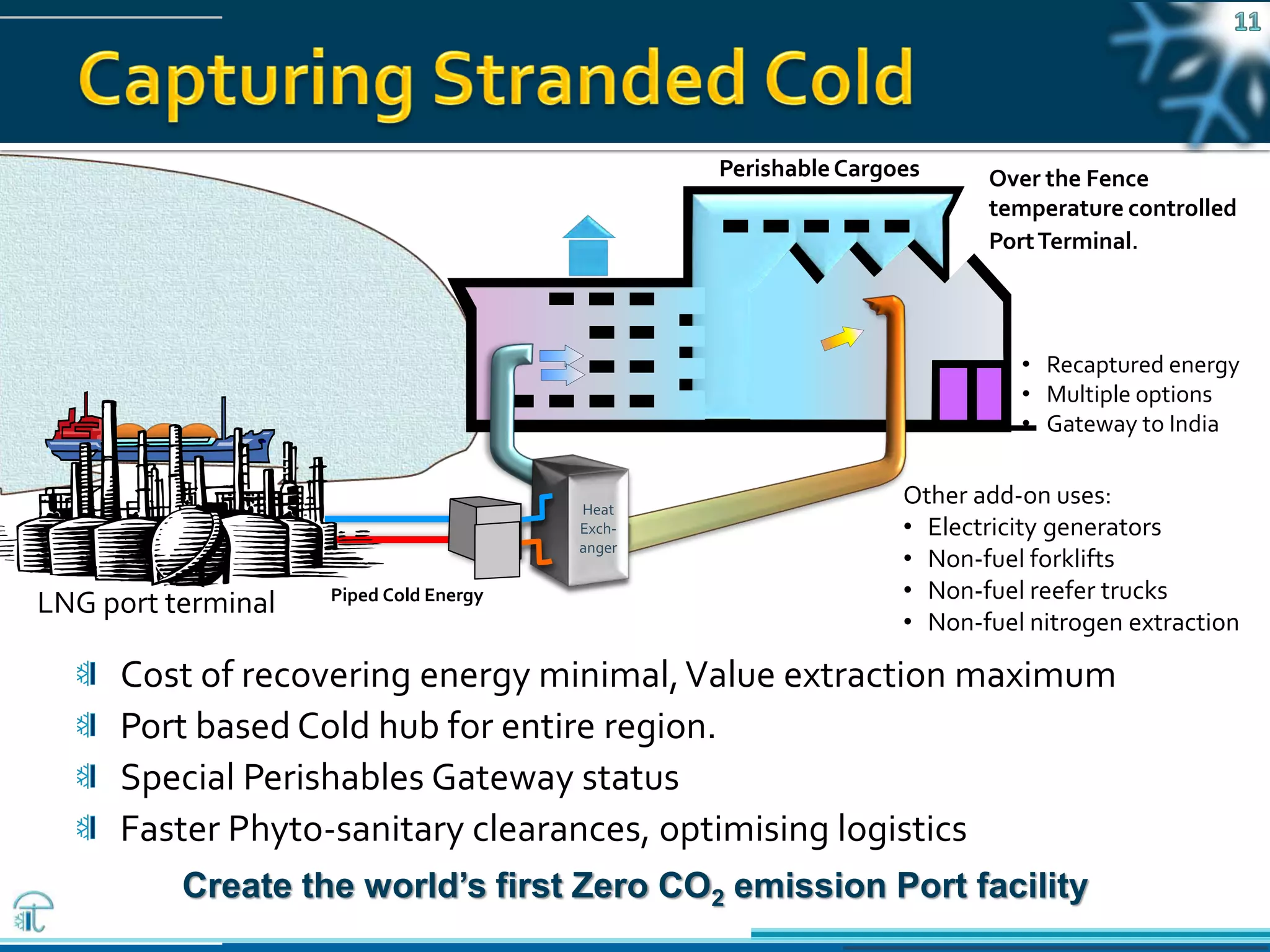

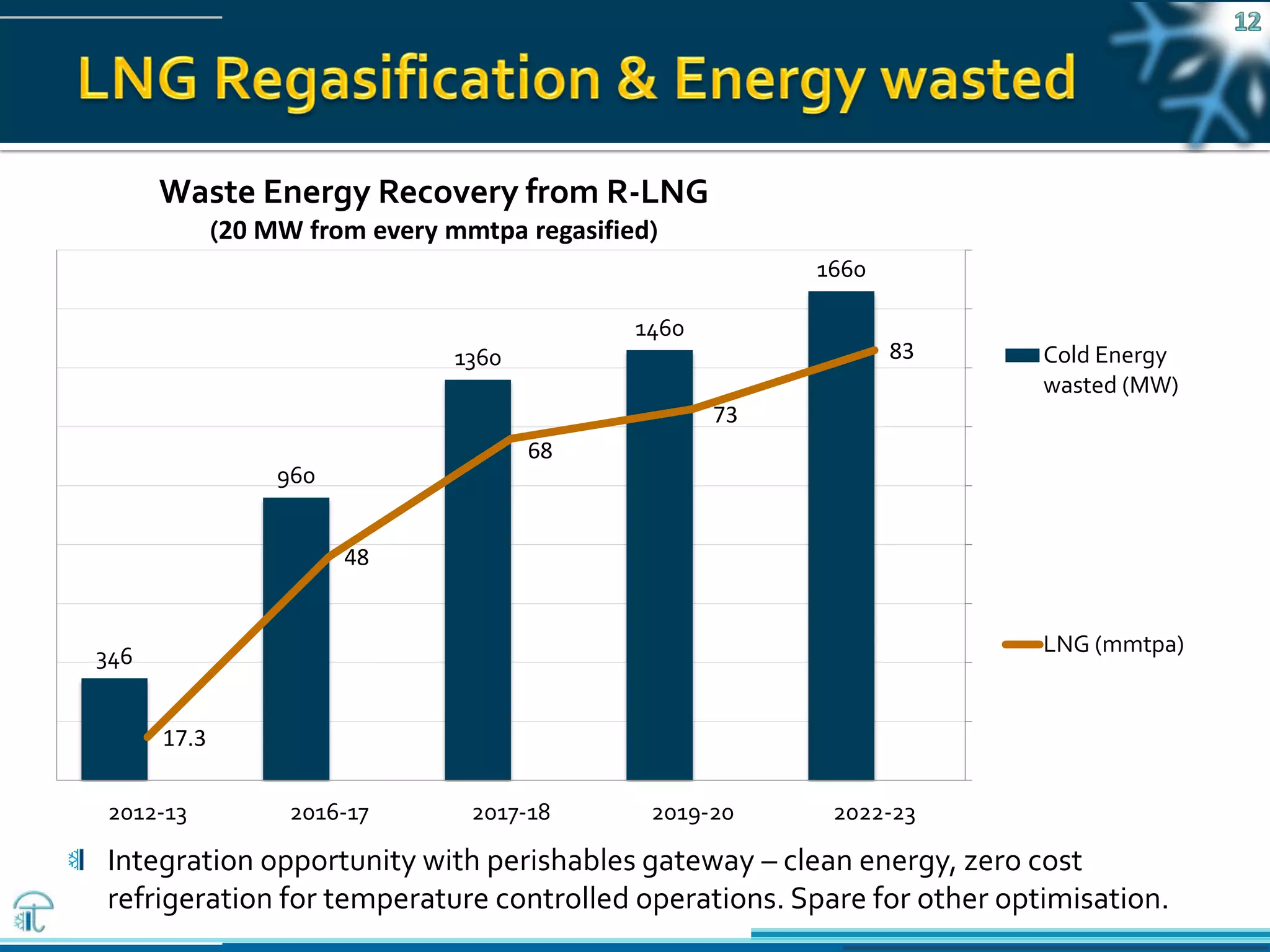

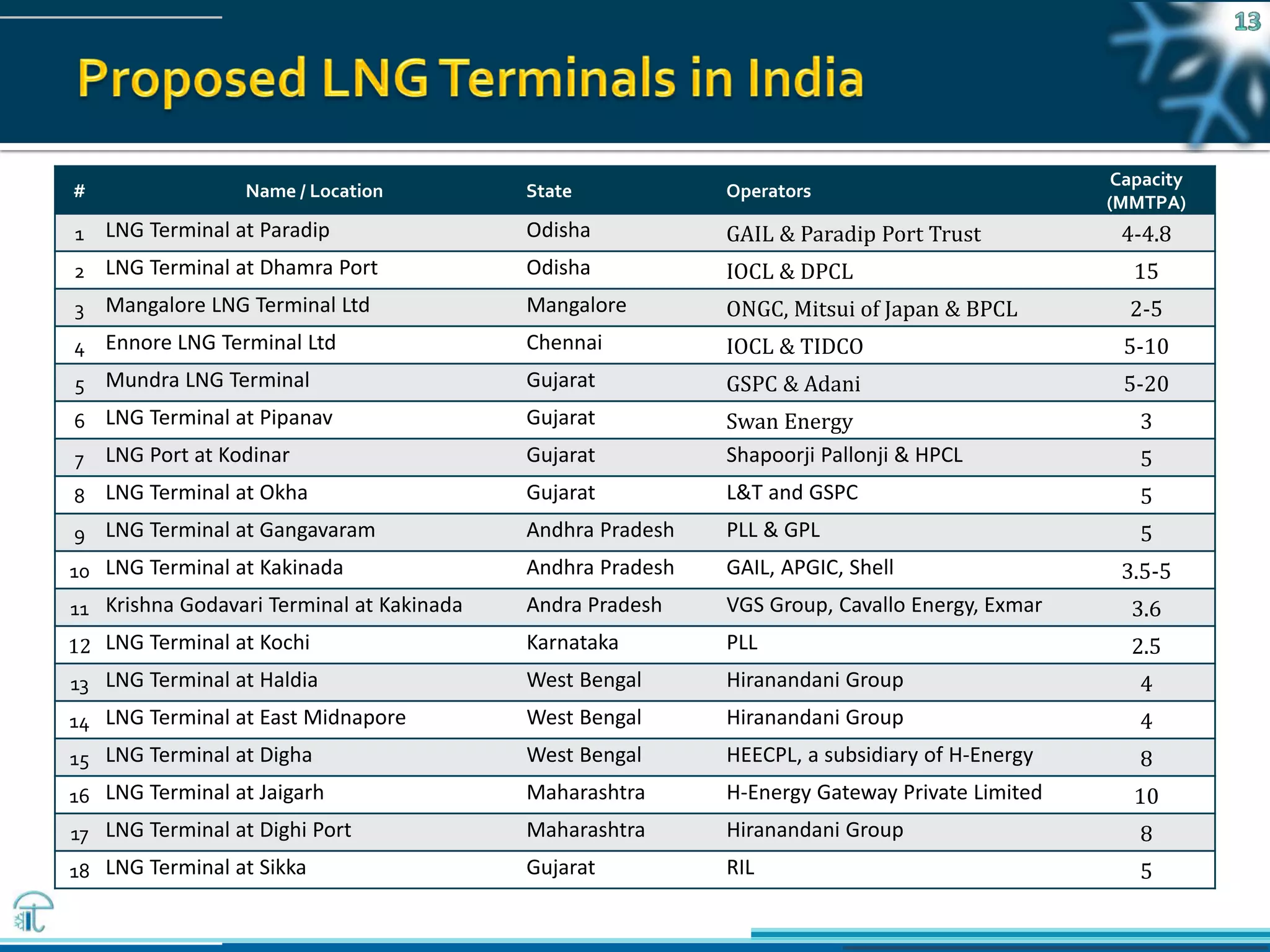

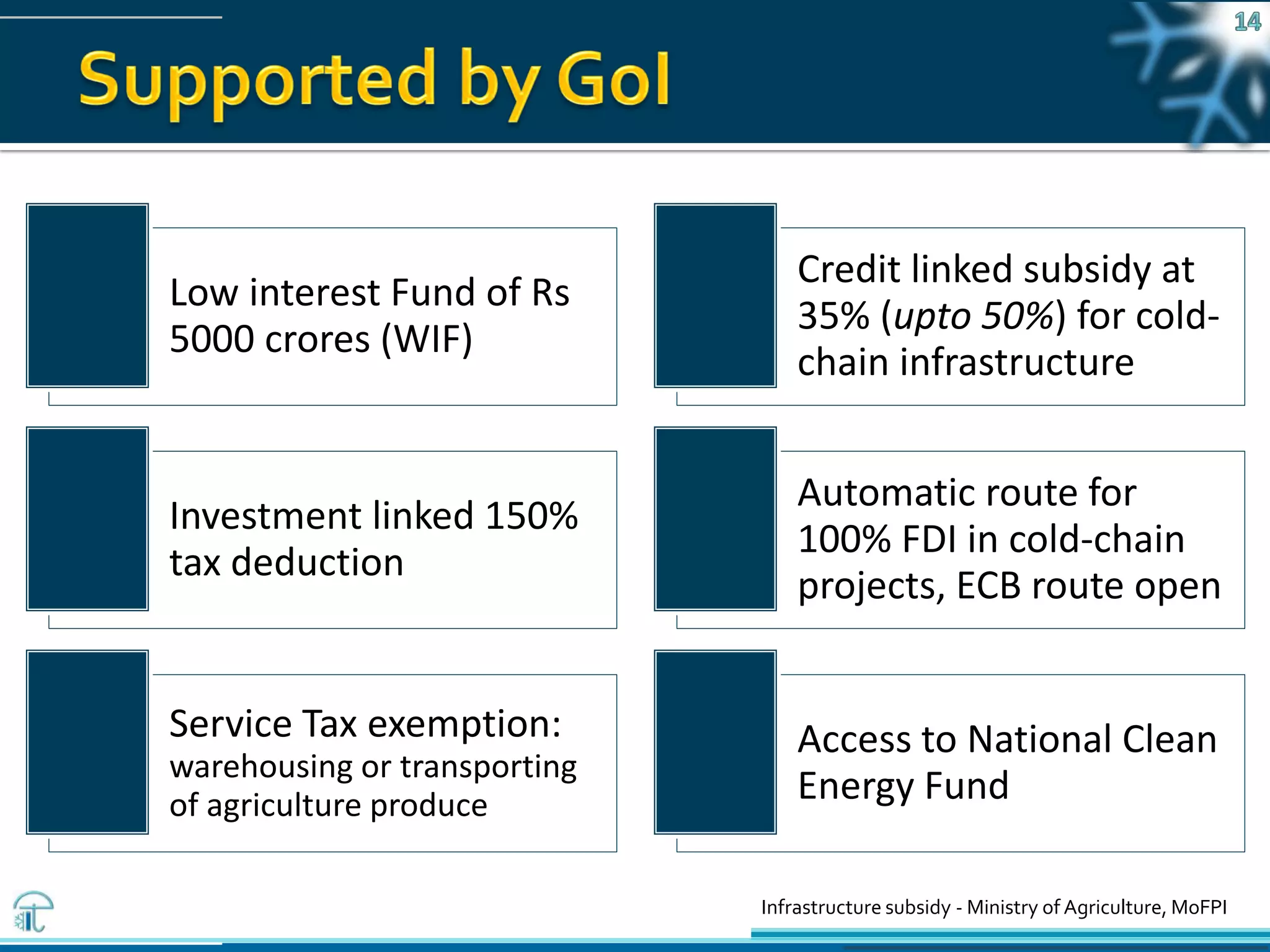

India is a major producer and consumer of agricultural goods and seafood. It has over 7,500 km of coastline with 200 ports handling 95% of international cargo. As incomes and spending rise, demand for quality perishable foods is increasing rapidly. However, India lacks integrated cold chain infrastructure to efficiently transport perishables from farms to markets. Recovering and utilizing stranded cold energy from LNG terminals presents a major opportunity. The 18 proposed LNG terminals across India could provide over 1,000 MW of clean, low-cost energy to power a national cold chain network and perishables logistics hub. This would minimize food waste and boost agricultural exports.