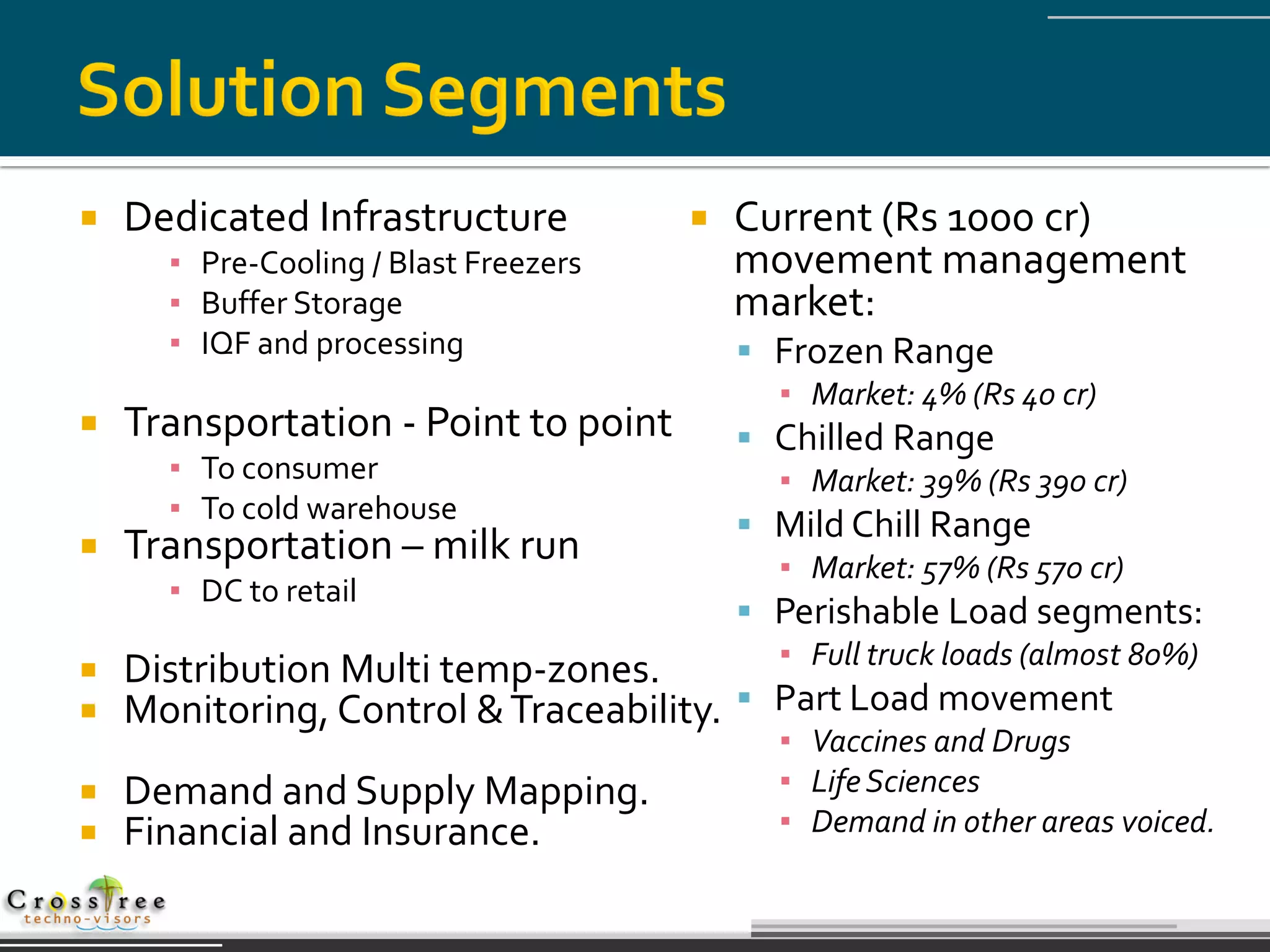

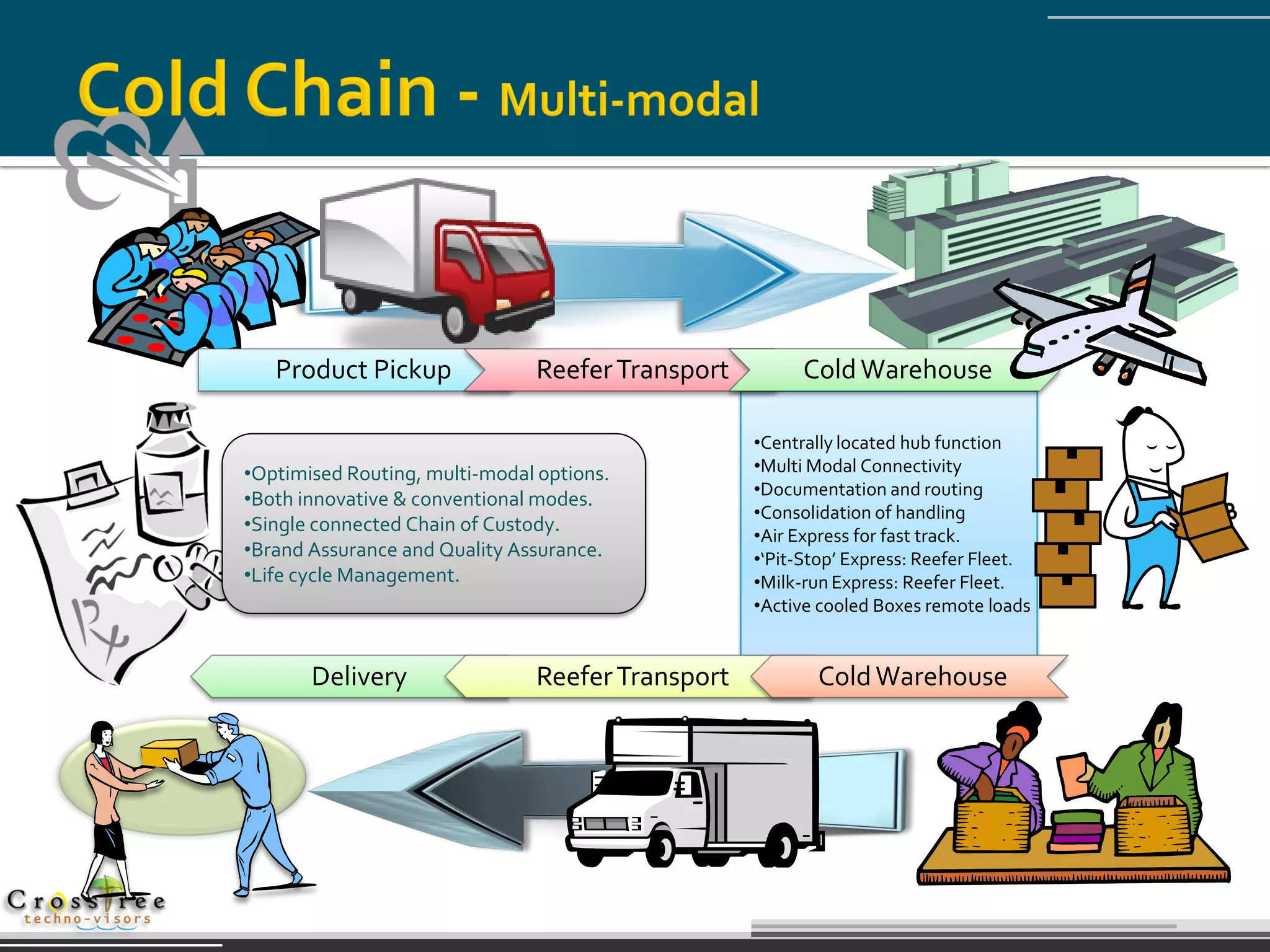

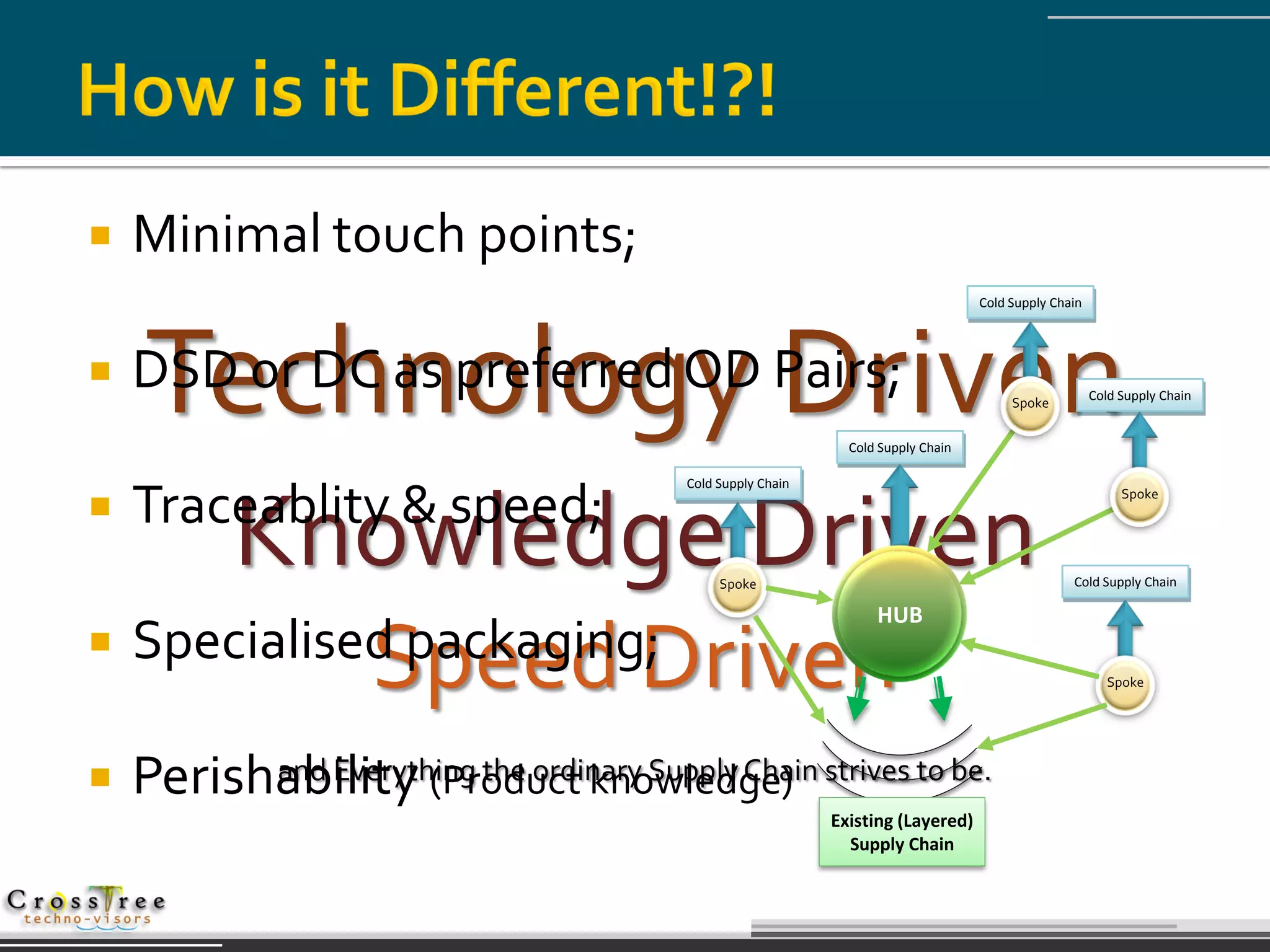

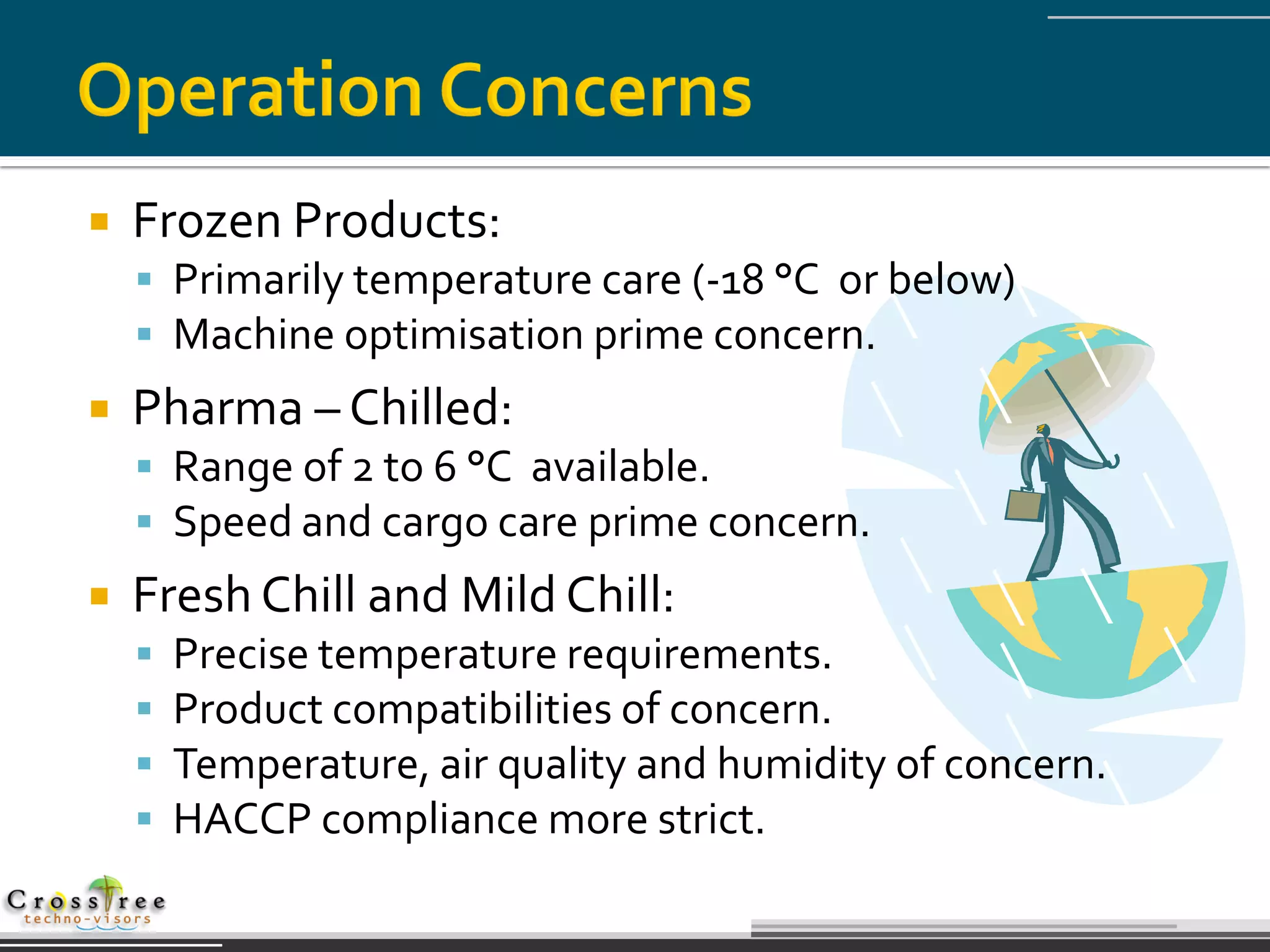

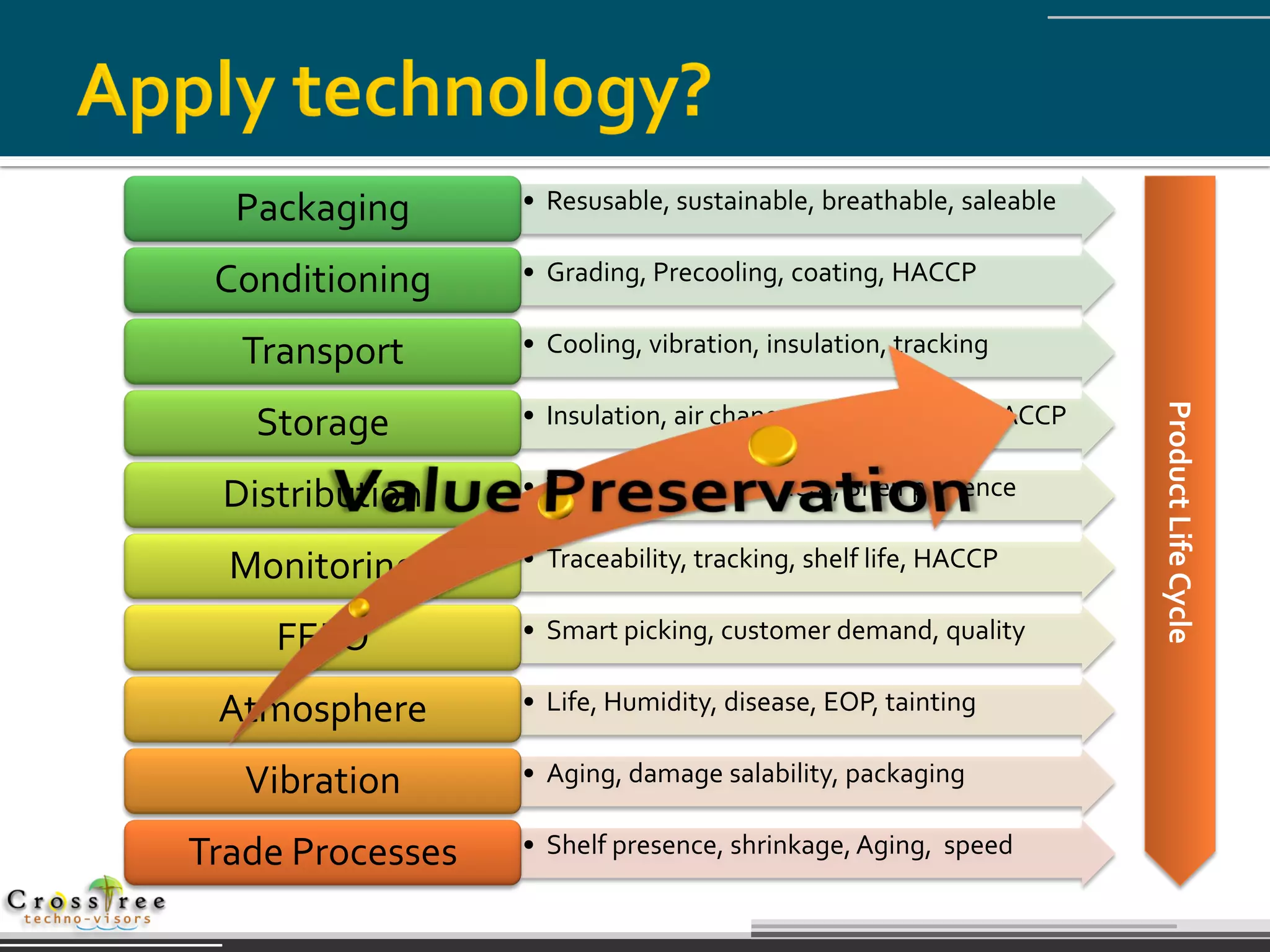

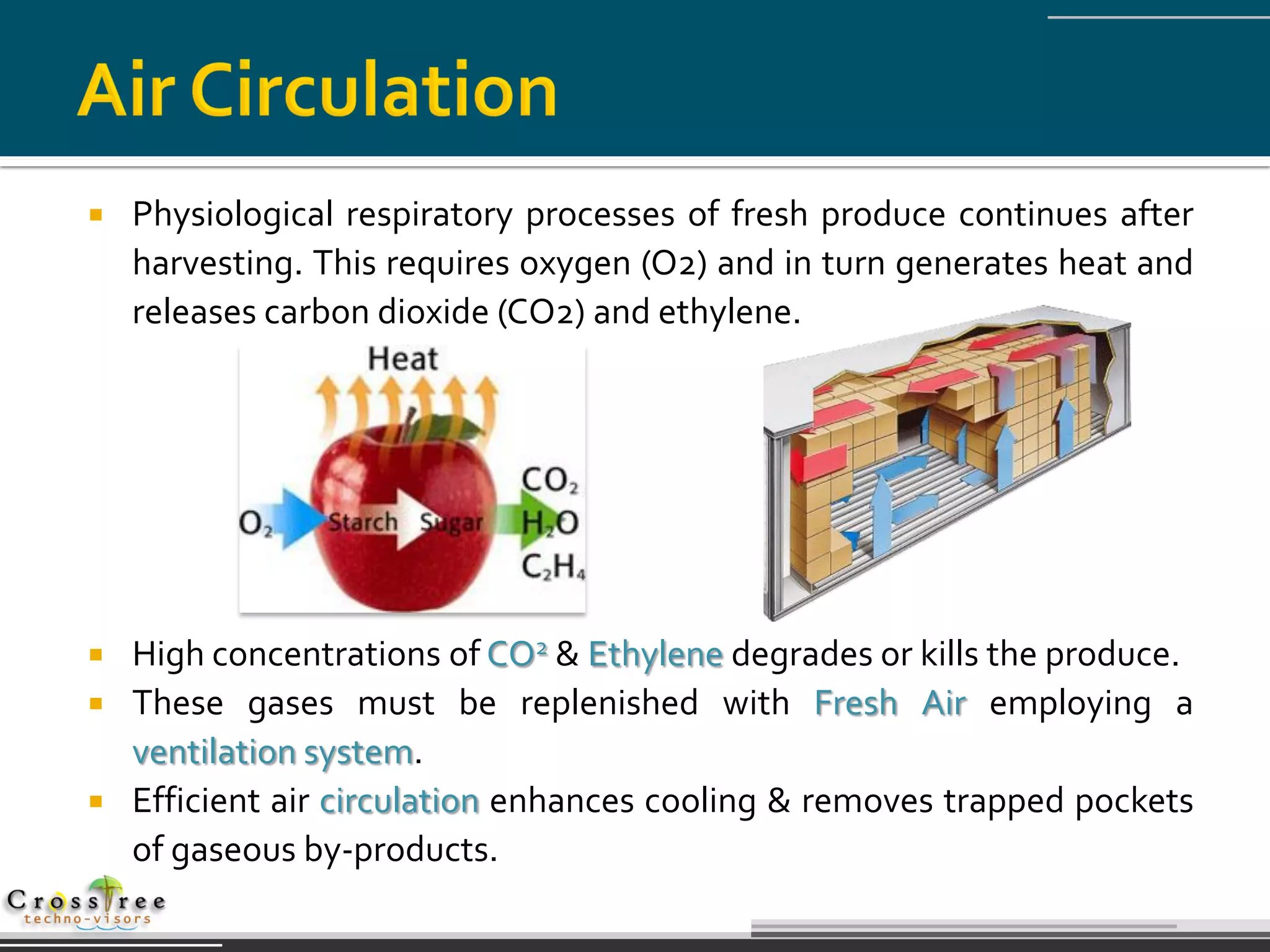

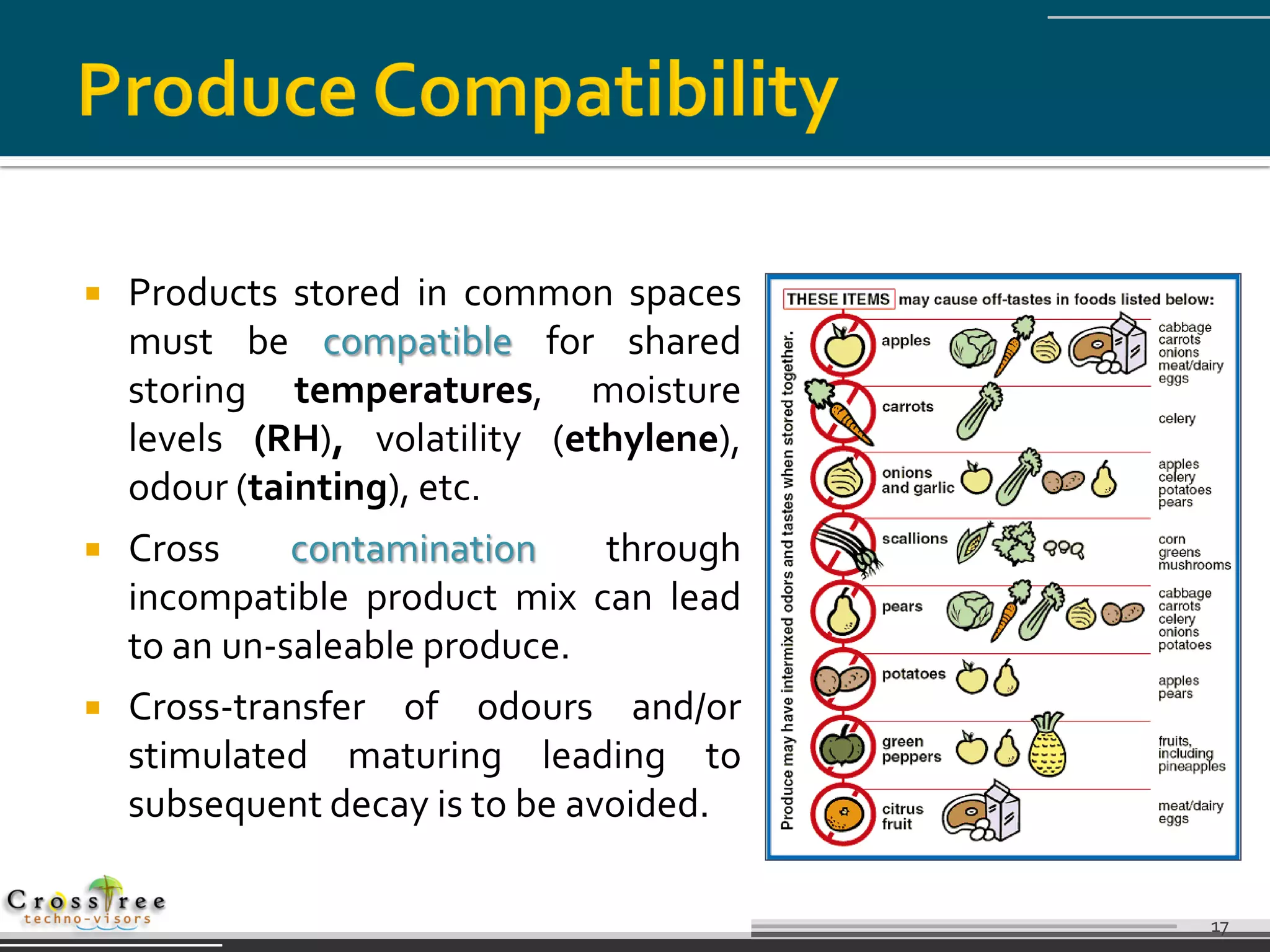

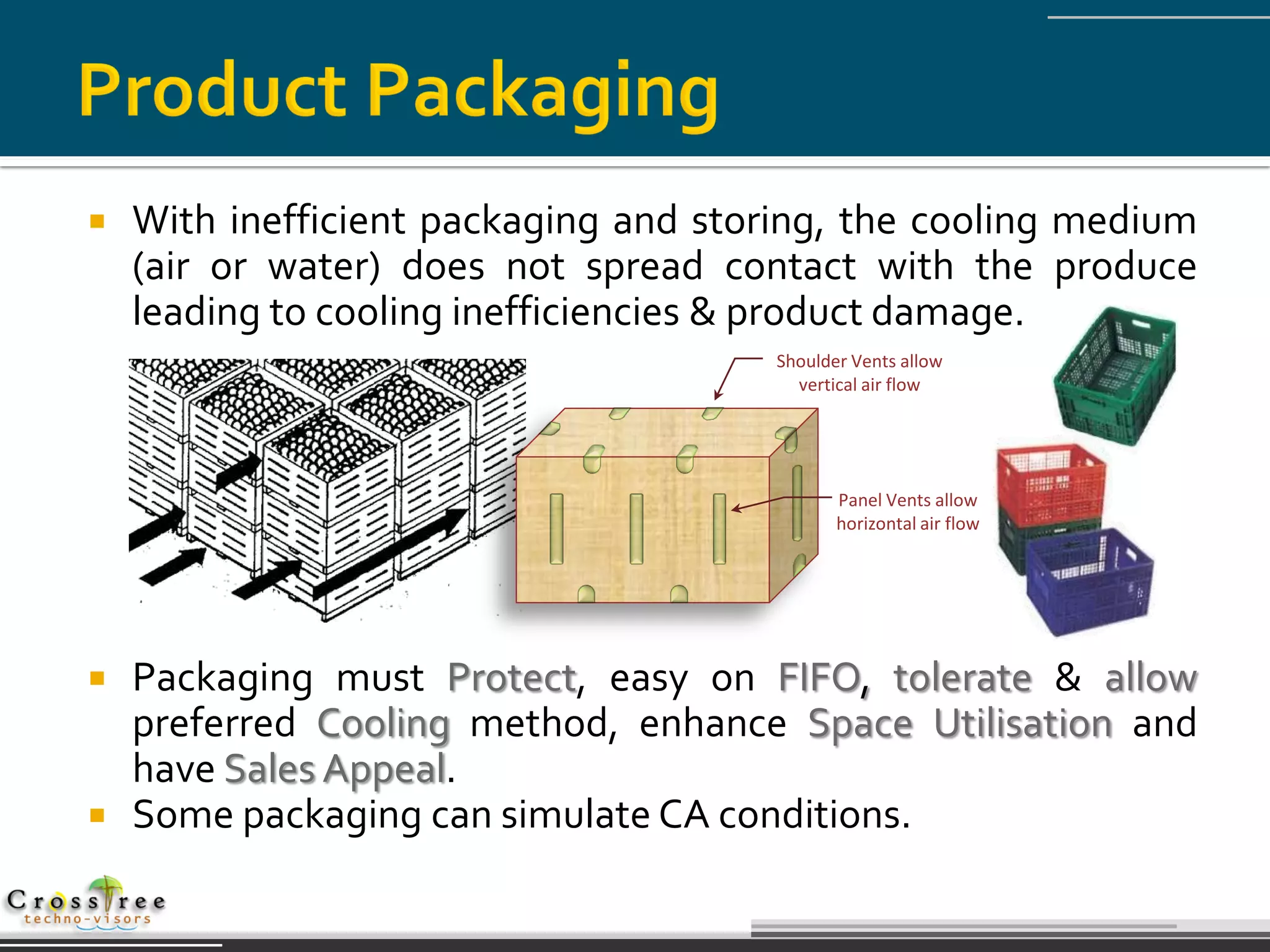

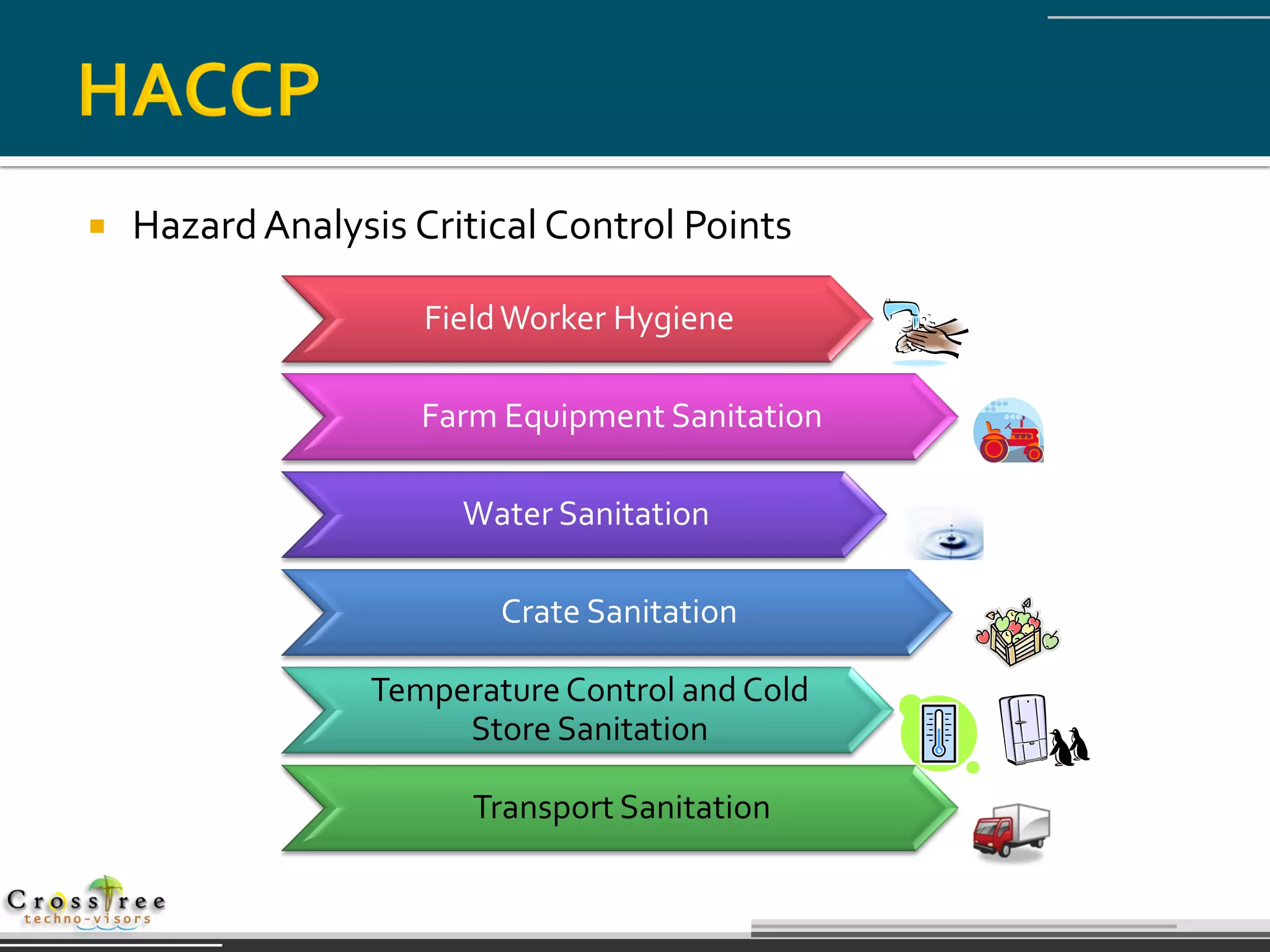

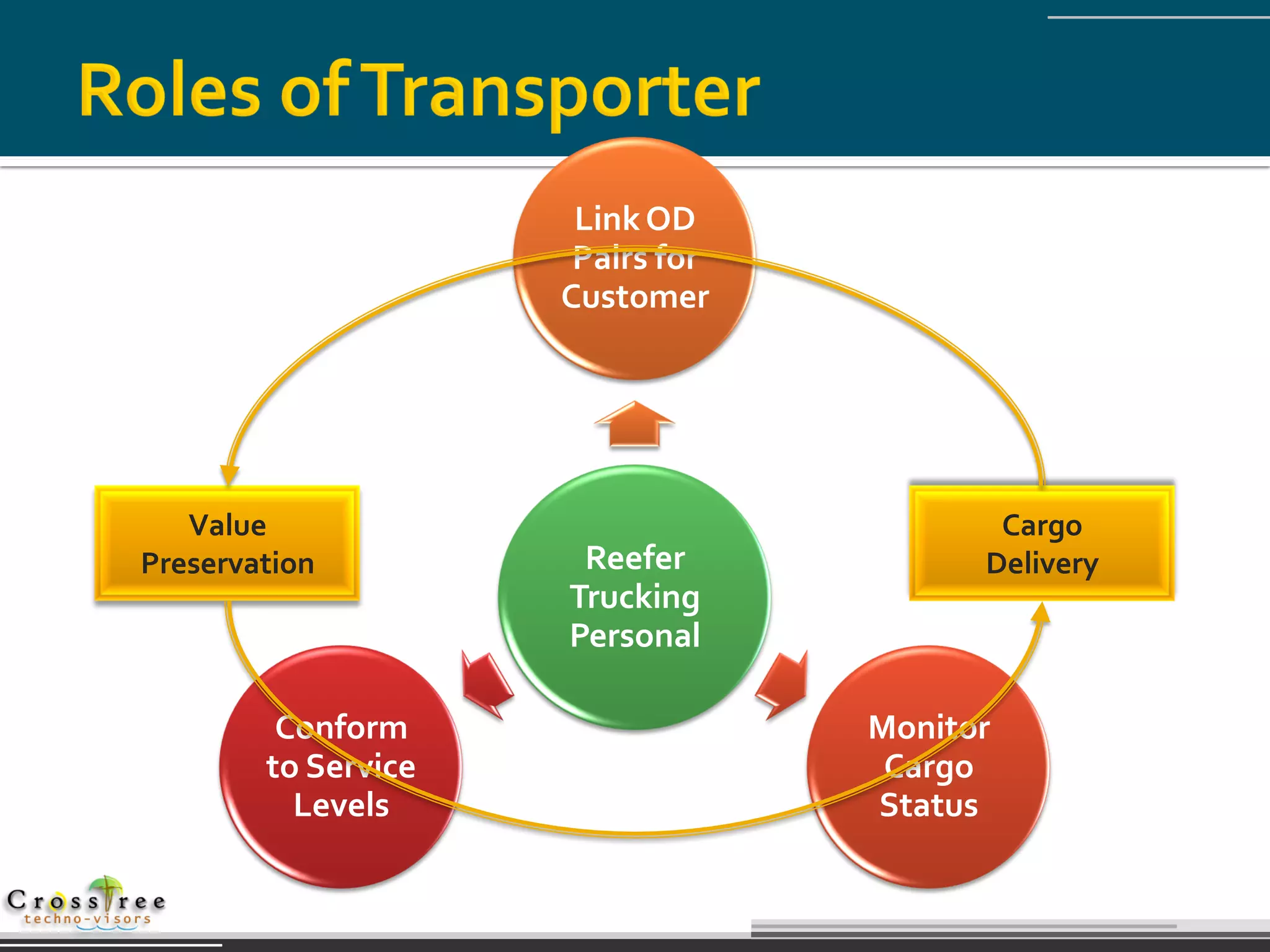

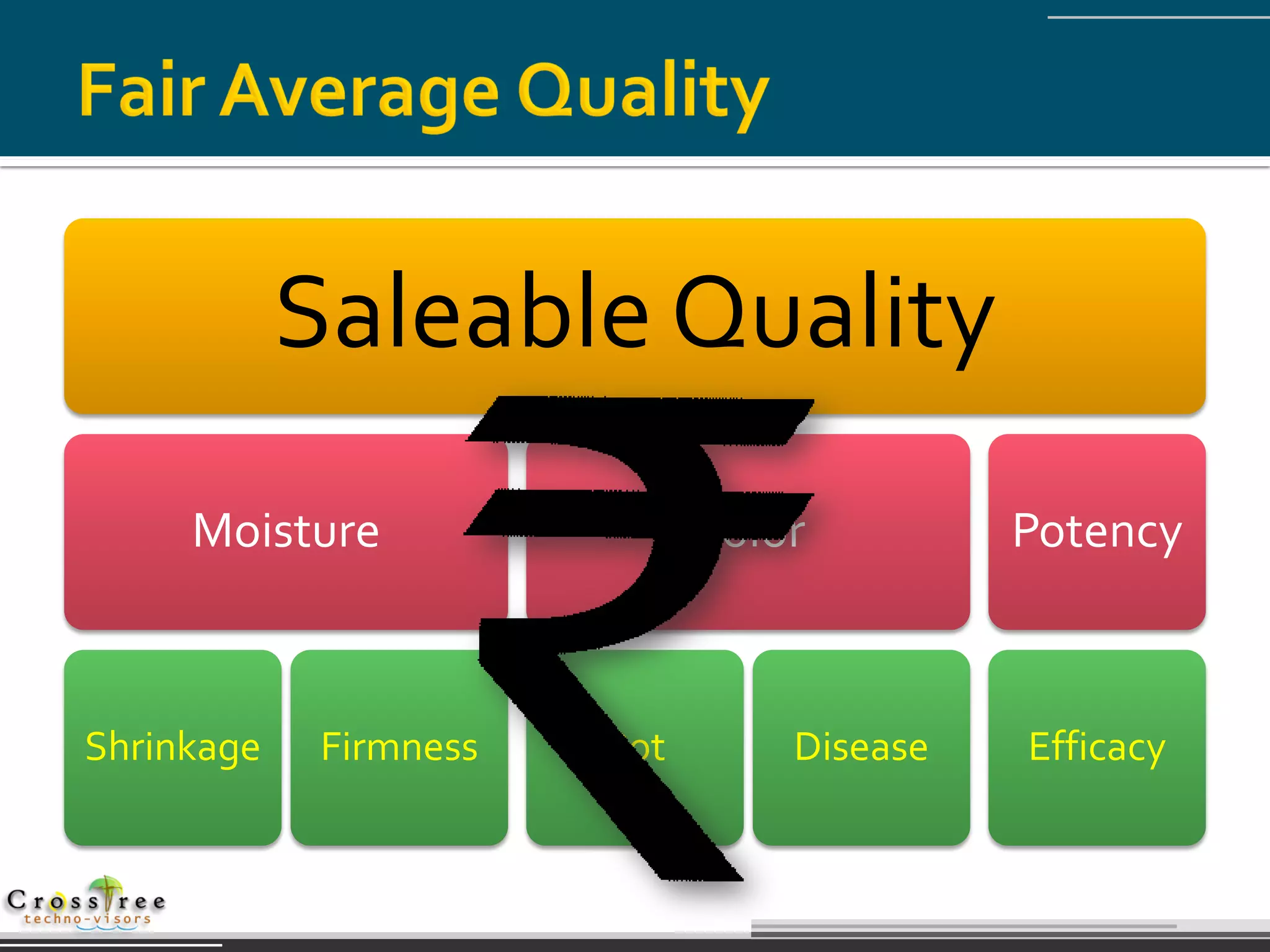

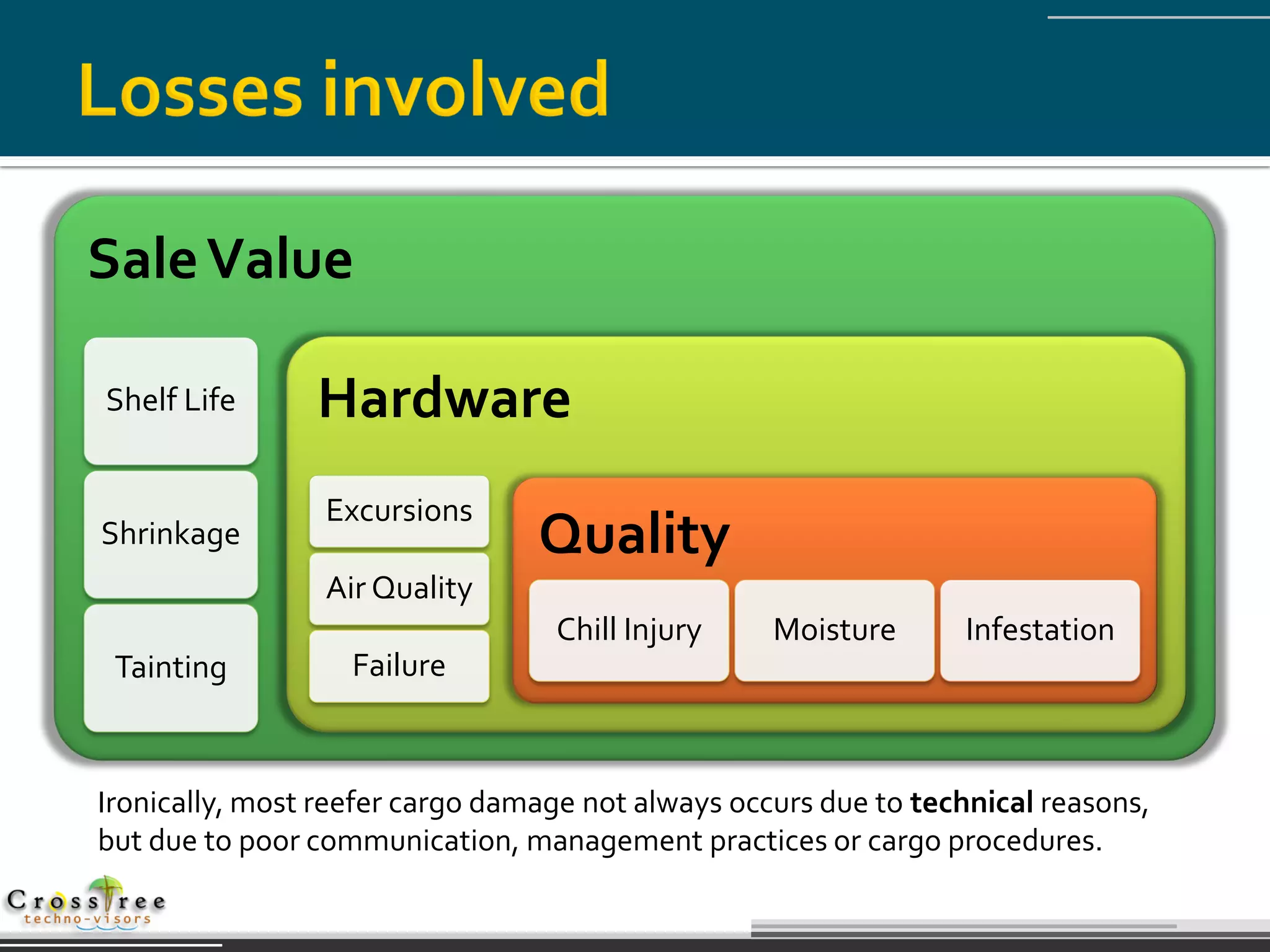

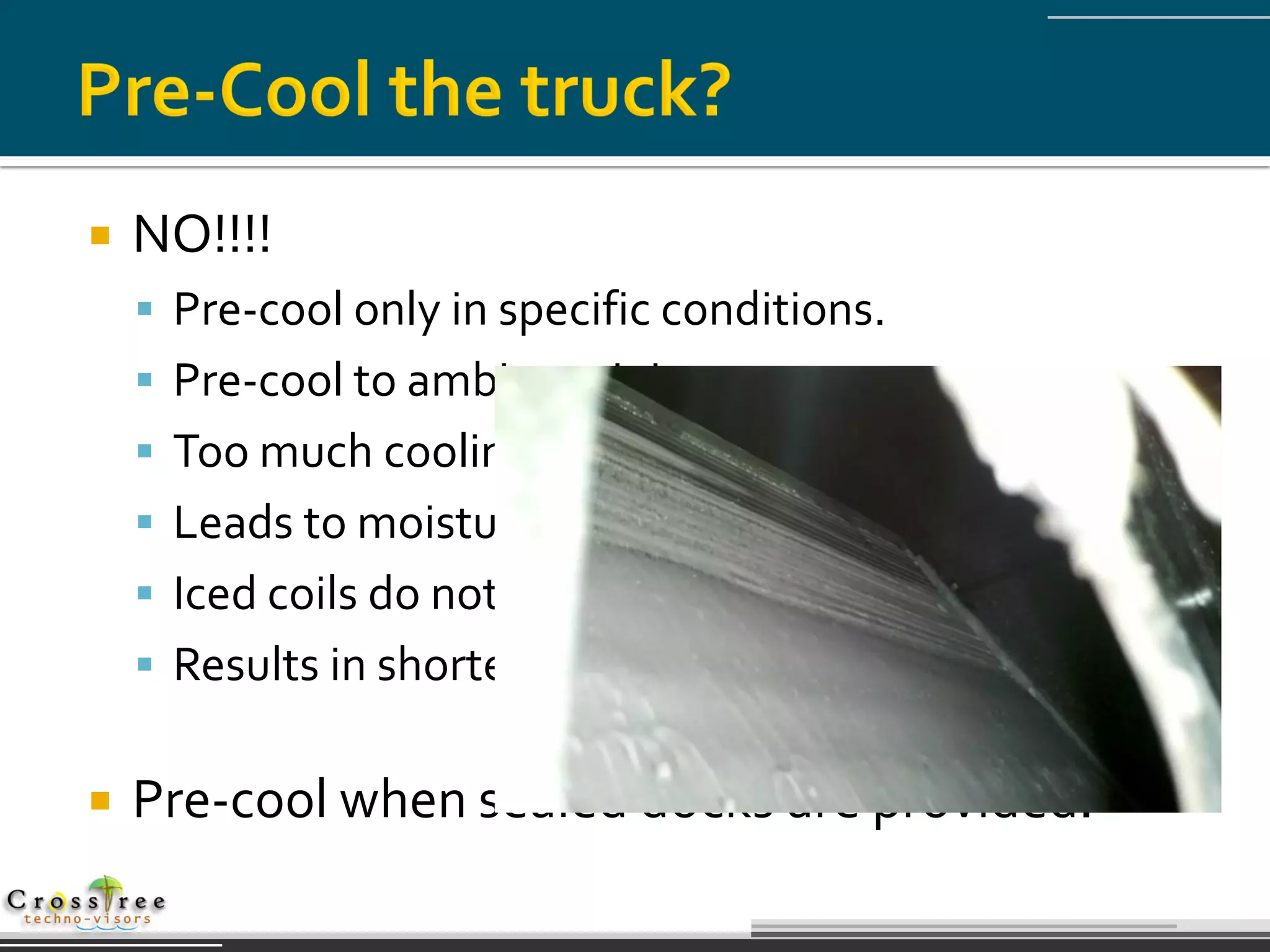

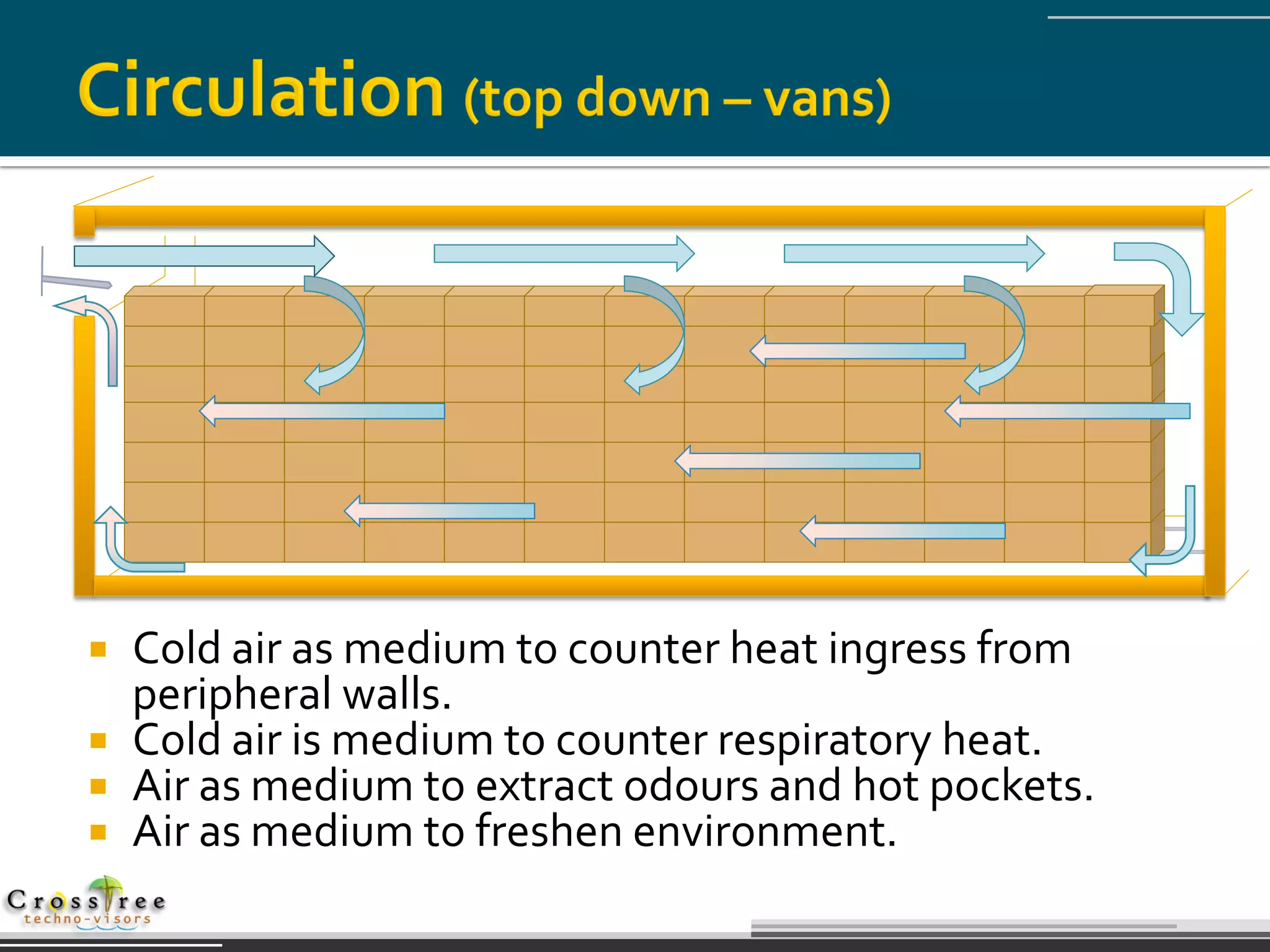

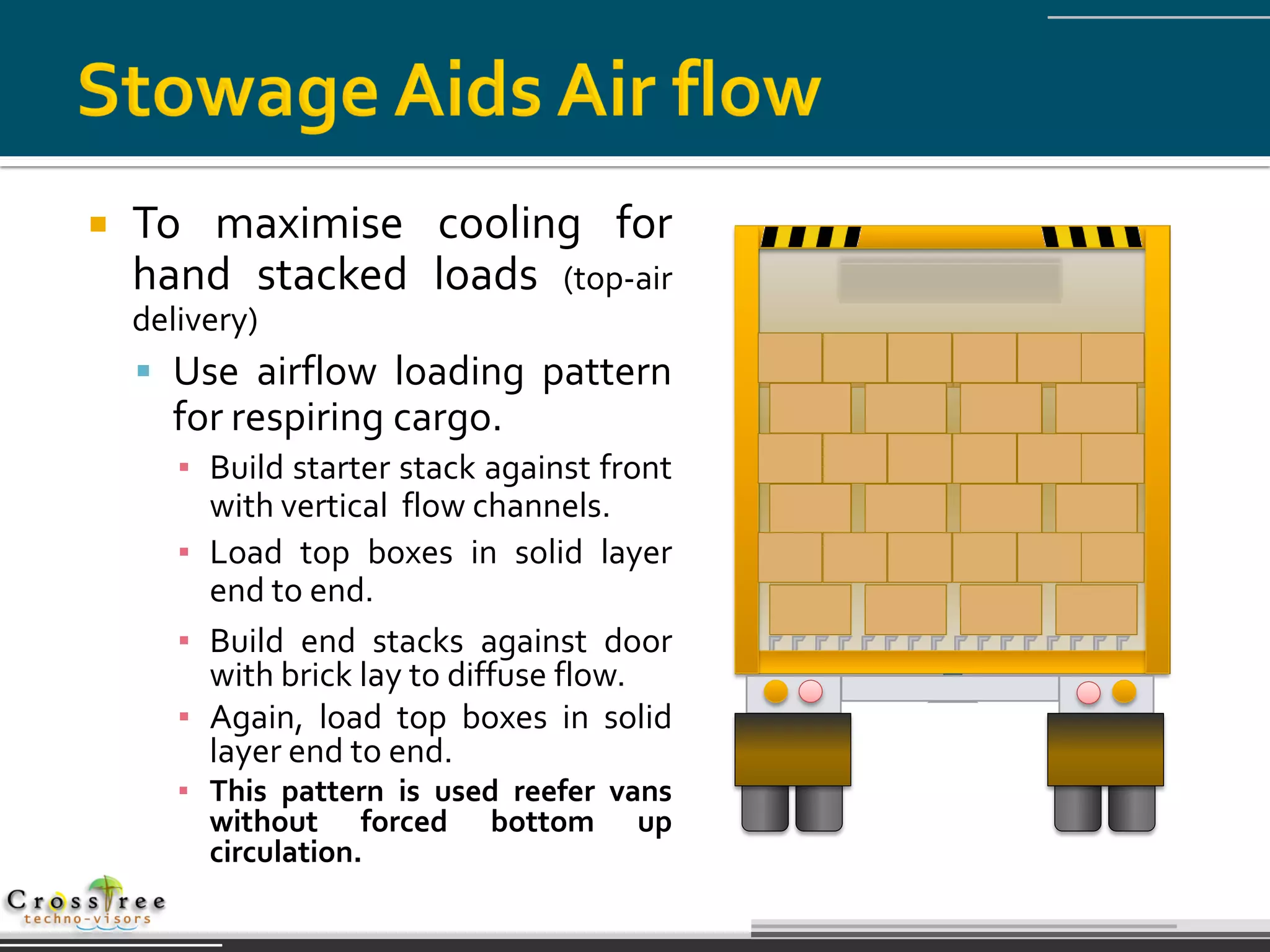

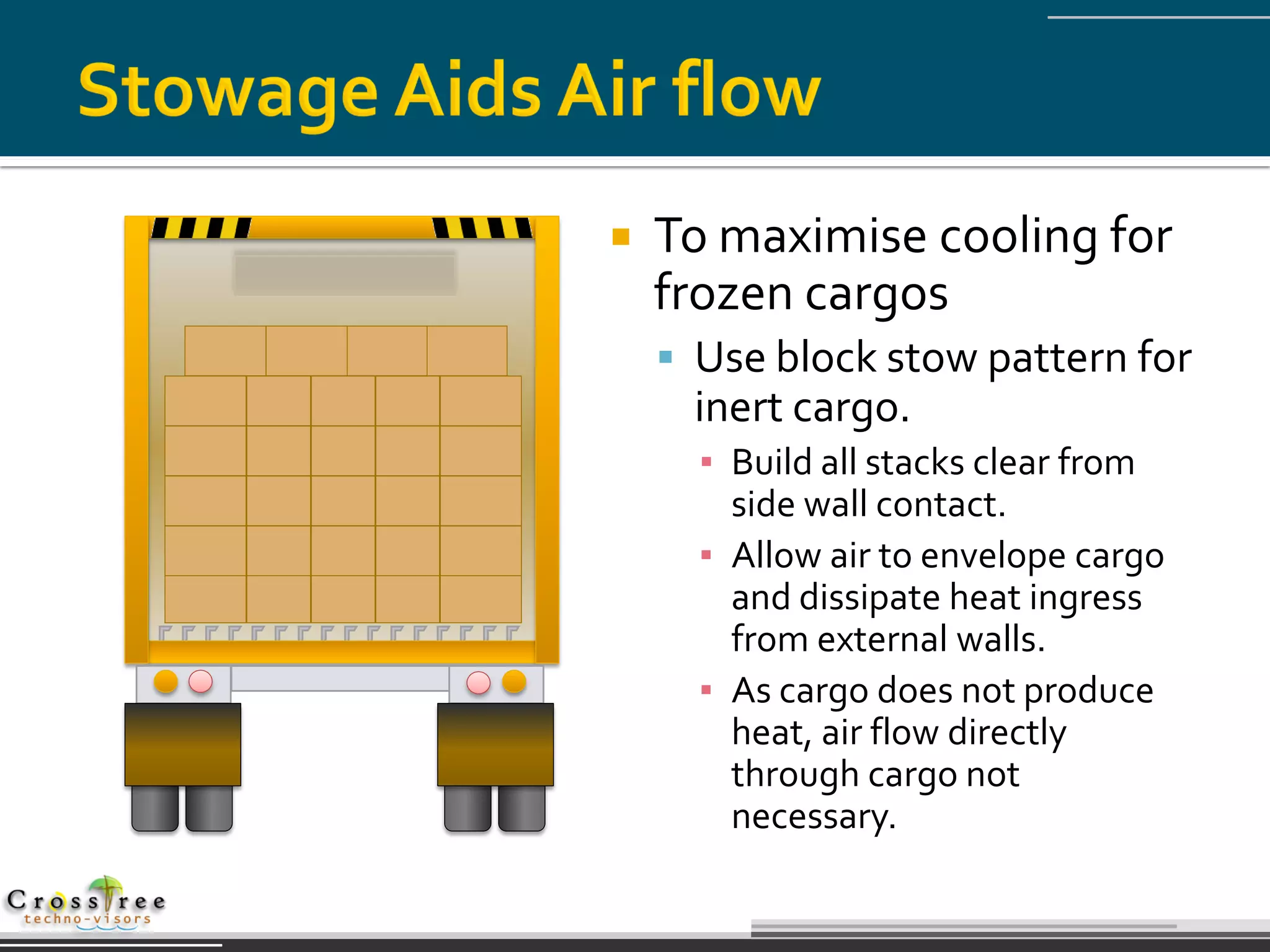

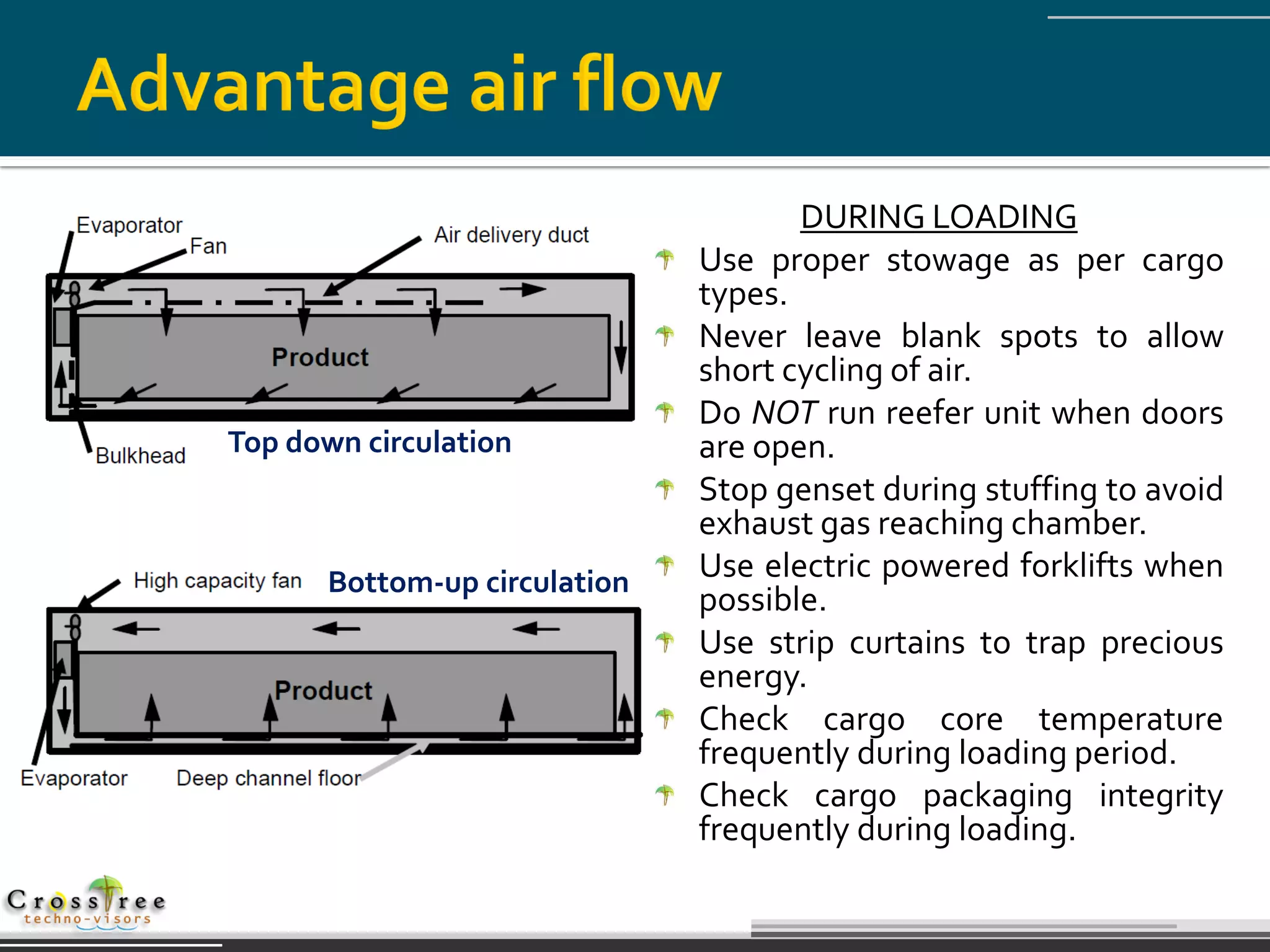

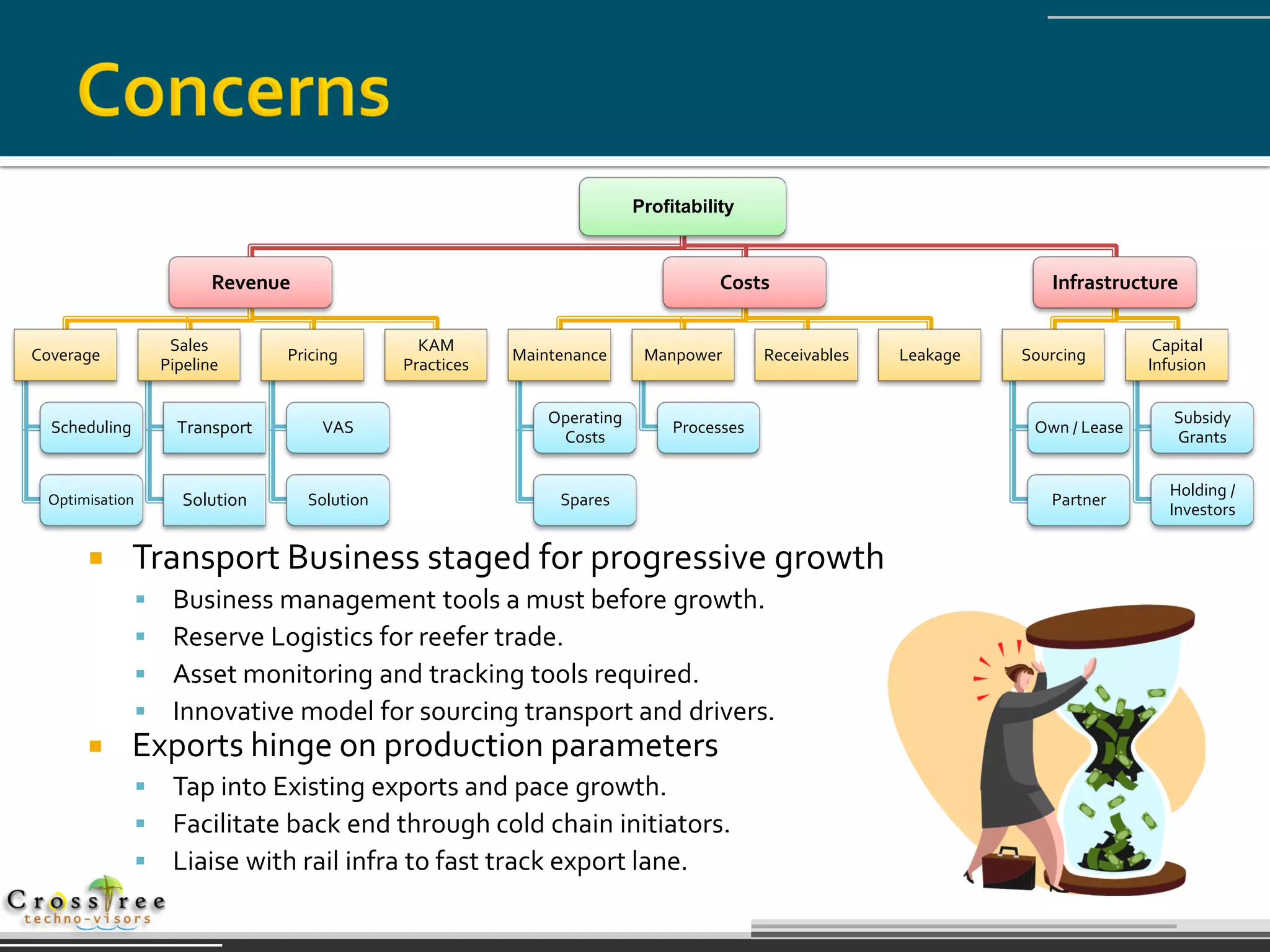

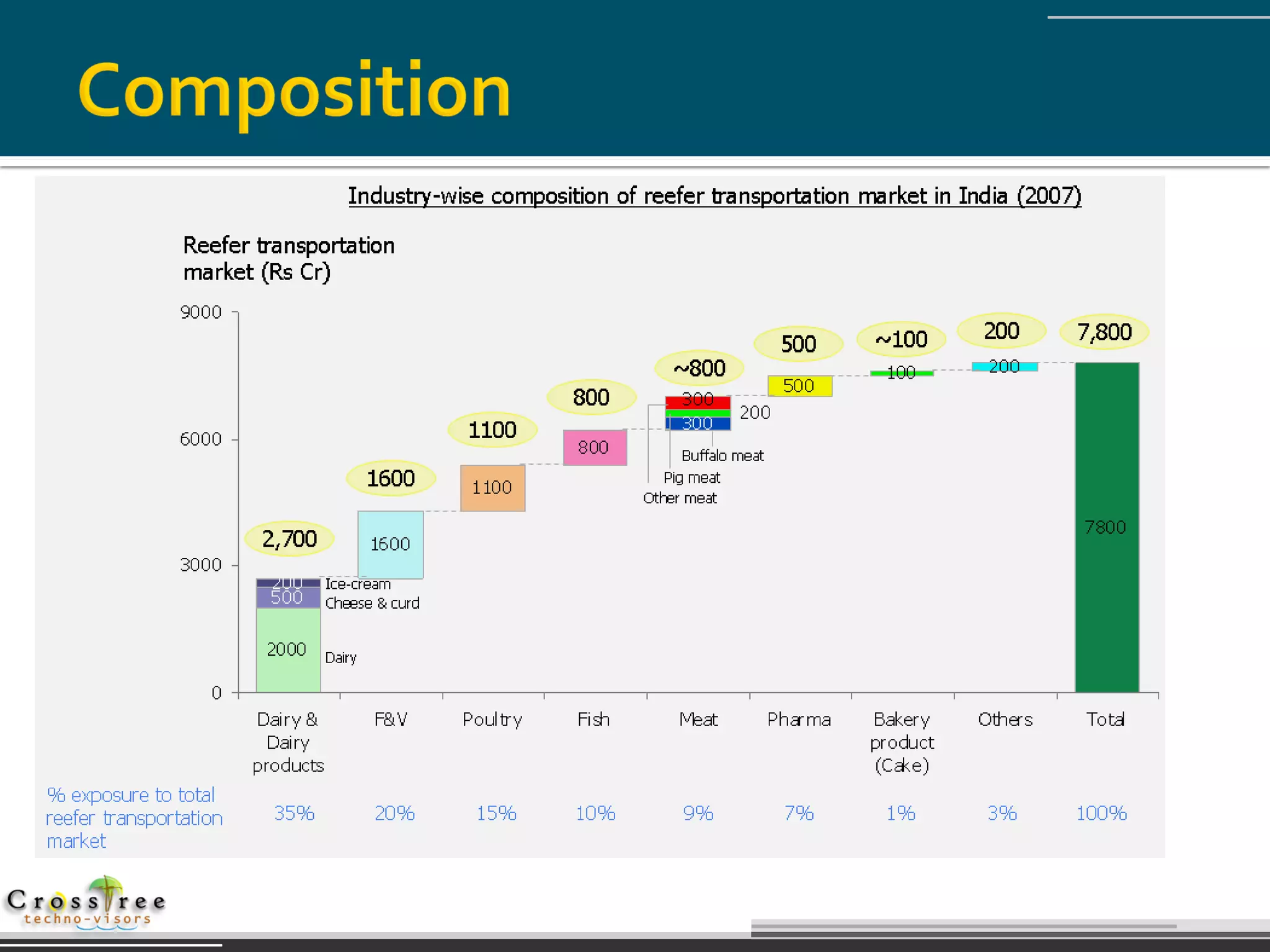

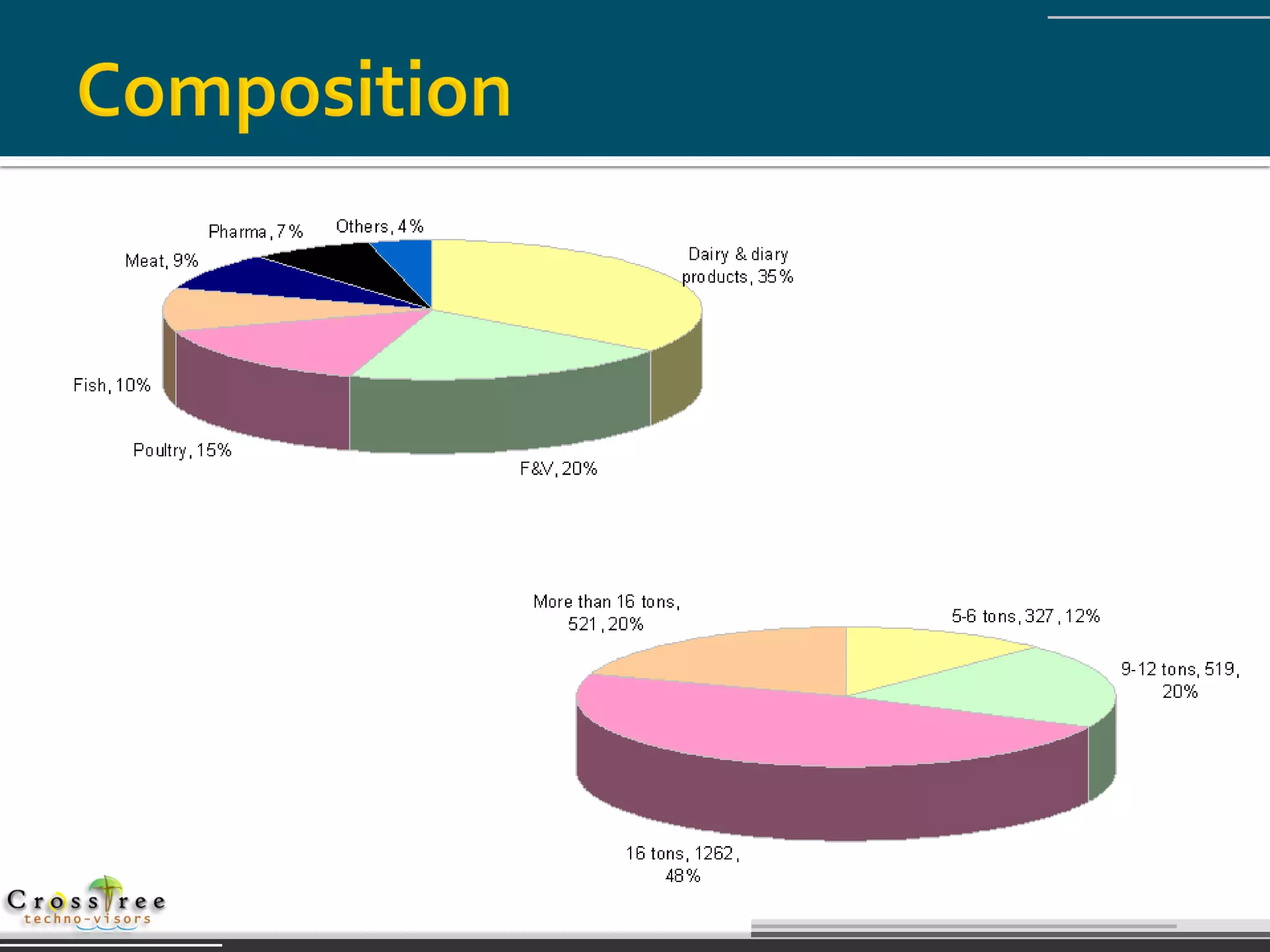

Captain Pawanexh Kohli, founder of Crosstree Techno-Visors, provides temperature-sensitive logistics services for the pharma, food, and agricultural sectors, focusing on cold chain efficiency and integrated service delivery. The document outlines the importance of temperature control, proper packaging, and logistics management in maintaining product quality and reducing spoilage during transport. It also highlights the challenges of managing cold chain assets, such as fragmented ownership and the need for improved communication and management practices.