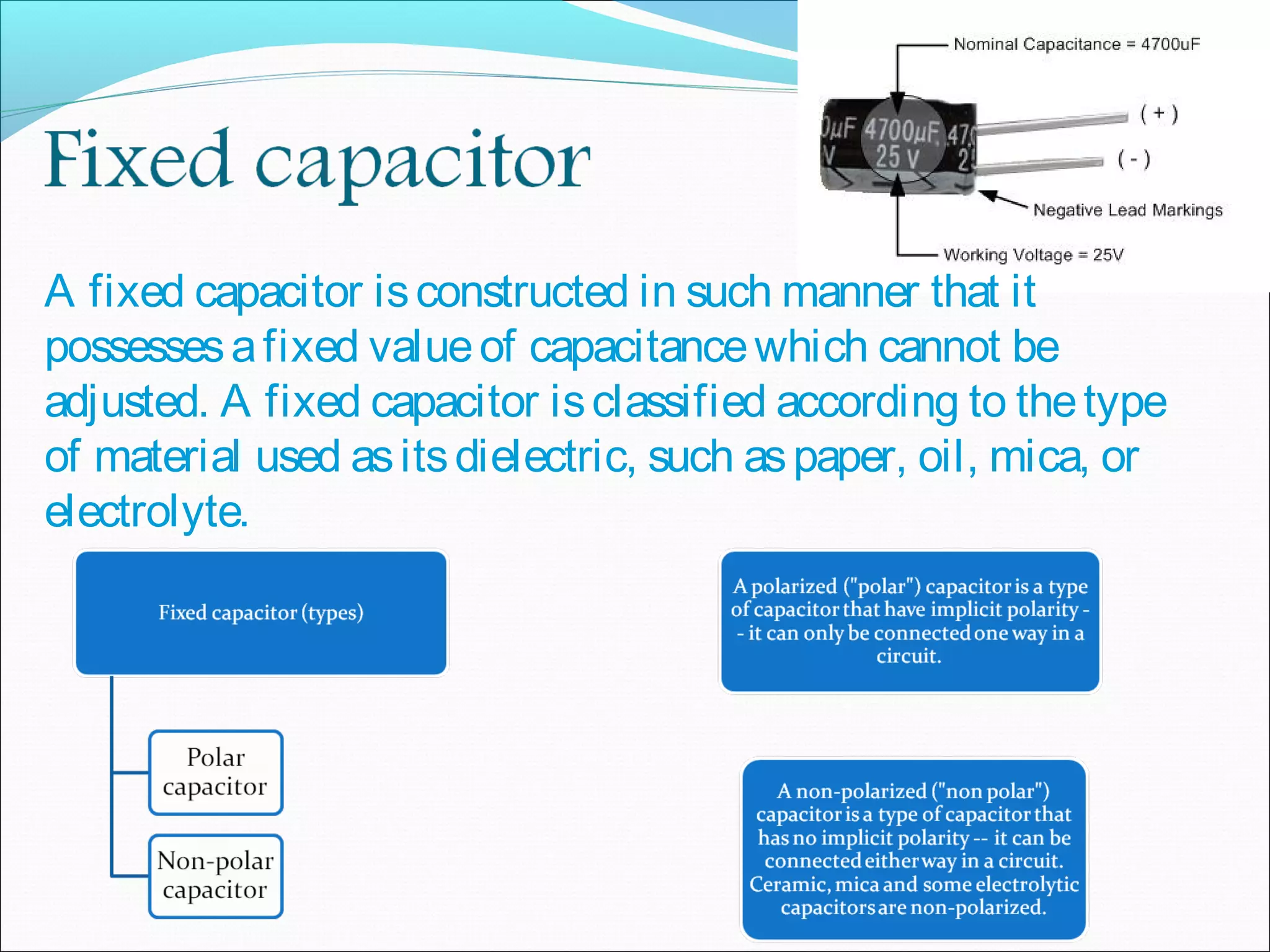

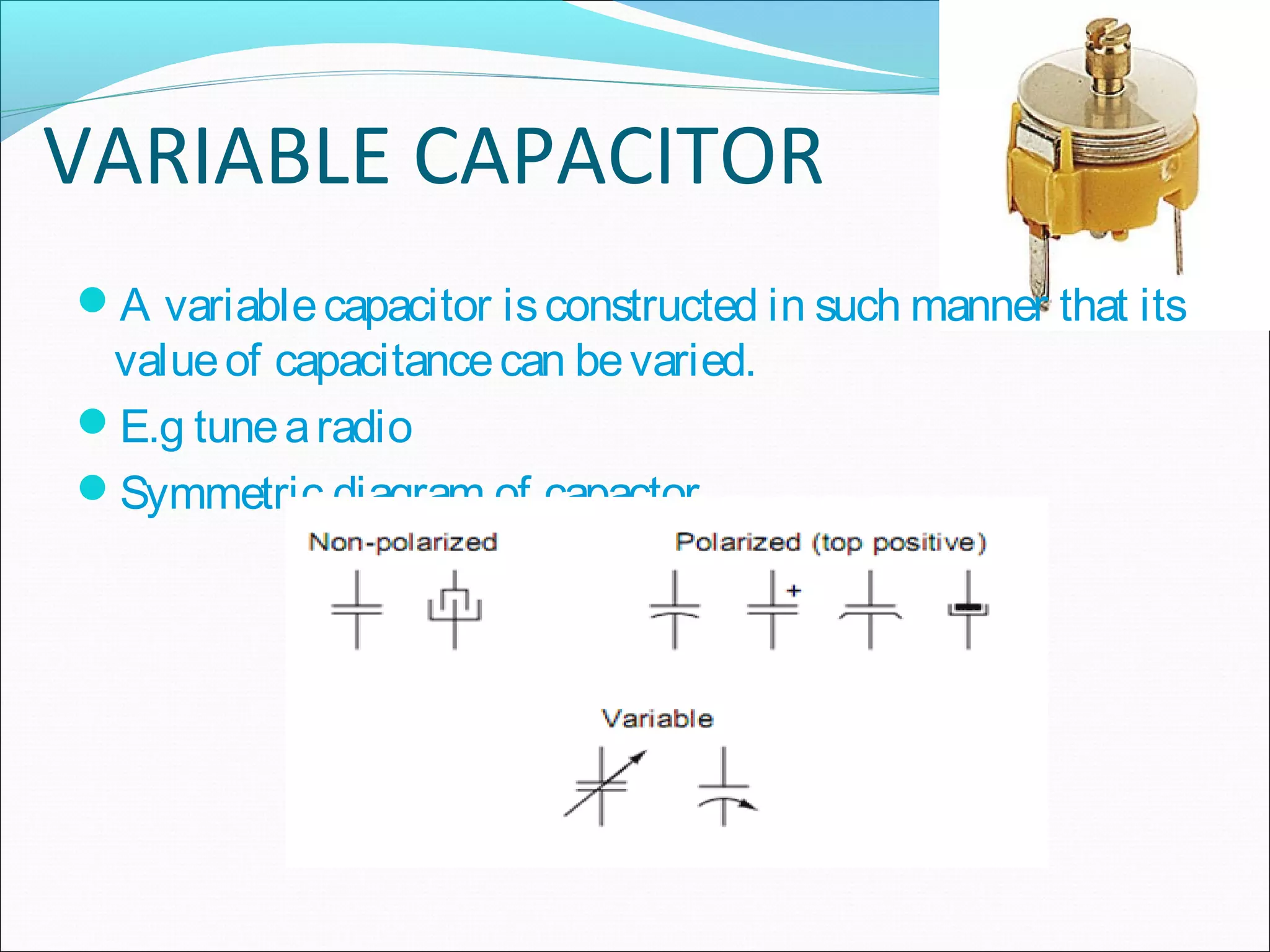

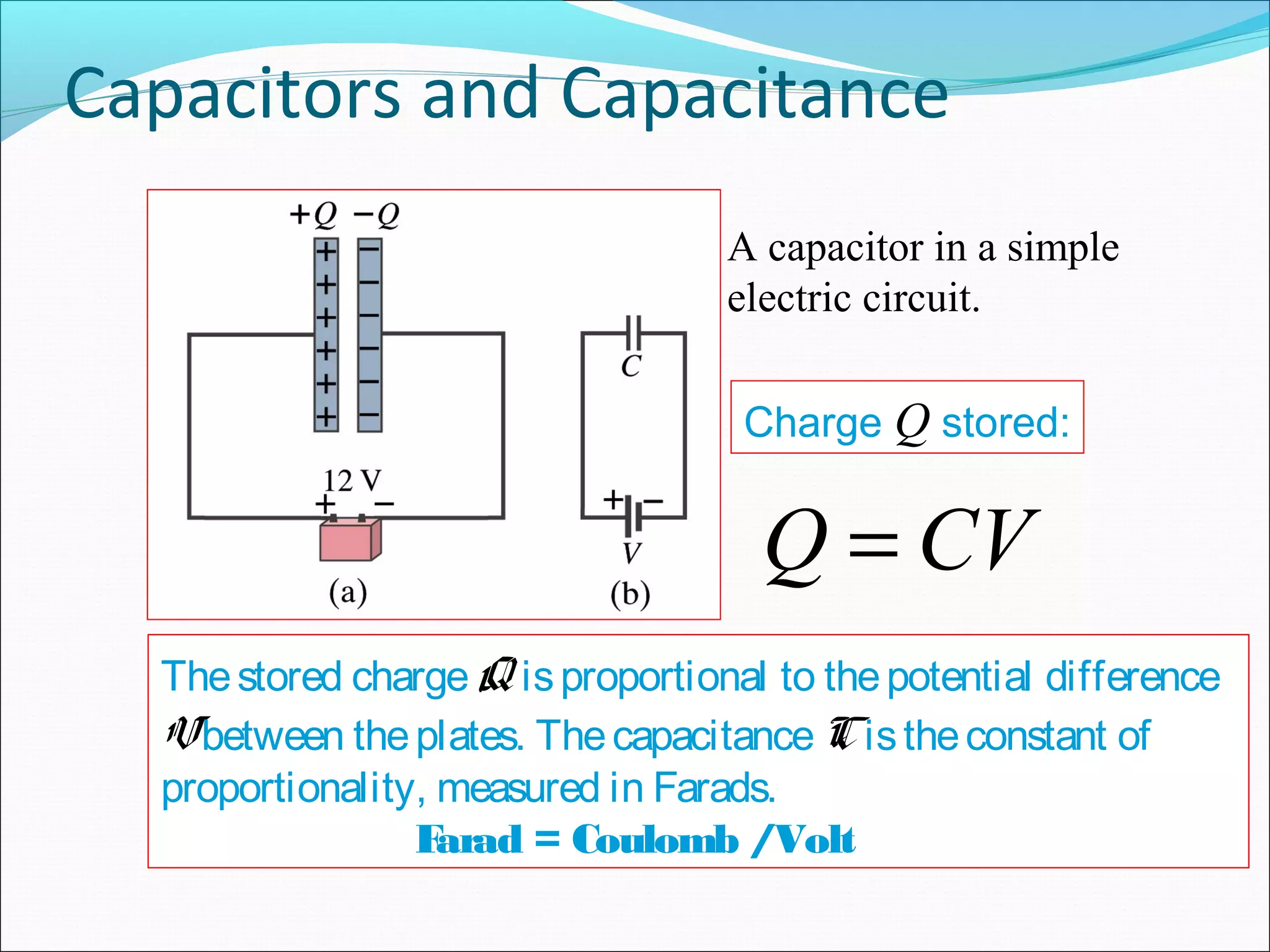

Capacitors store electric charge and consist of two conductors separated by an insulator. They have many applications in radios, electronic circuits, fans, and motors. There are two types of capacitors - fixed capacitors with a fixed capacitance value, and variable capacitors with an adjustable capacitance value. The charge stored by a capacitor is proportional to the potential difference between its plates, and the capacitance is the constant of proportionality. Energy efficient motors improve efficiency by reducing losses through improved design and materials, allowing them to provide the same energy output while using less energy input.