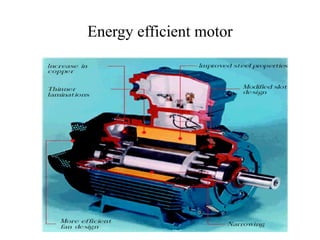

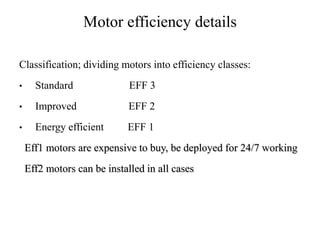

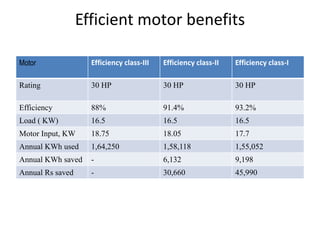

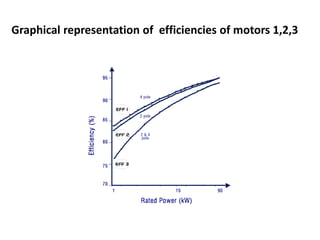

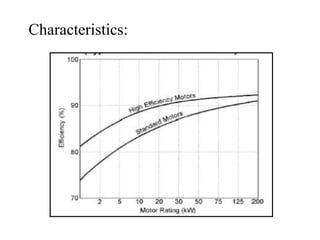

Energy efficient motors (EEMs) use less input power than standard efficiency motors to produce the same output, saving energy. EEMs are manufactured with improvements like higher quality steel and copper that reduce losses. While EEMs have higher initial costs, their energy savings lead to payback periods of less than five years. Wide adoption of EEMs in industry could significantly reduce electricity usage and costs while lowering environmental impacts from reduced greenhouse gas emissions during electricity production.