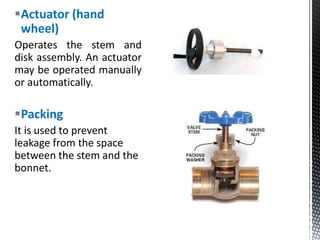

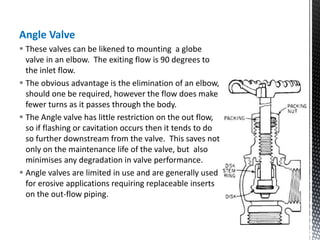

Valves are devices that regulate the flow of fluids by opening, closing, or partially obstructing passageways. They perform functions like starting and stopping flow, varying the flow amount, and controlling flow direction. Valves are classified based on their mechanical motion as either linear motion valves where the closure member moves in a straight line, or rotary motion valves where the closure member moves in an angular or circular path. Basic valve parts include the body, bonnet, trim (internal elements), actuator, and packing. Common valve types include gate valves, globe valves, ball valves, butterfly valves, plug valves, diaphragm valves, and angle valves. Each type has distinct characteristics regarding flow control, maintenance requirements, and applications.