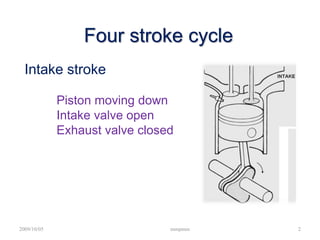

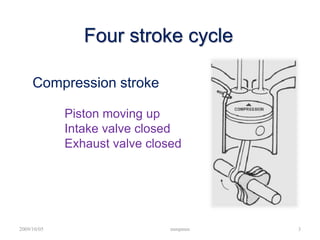

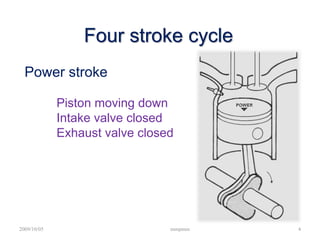

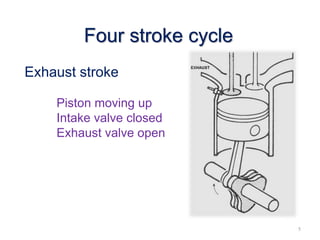

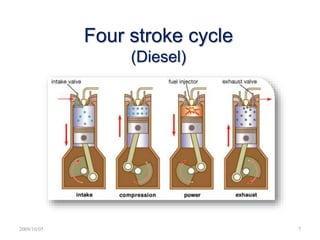

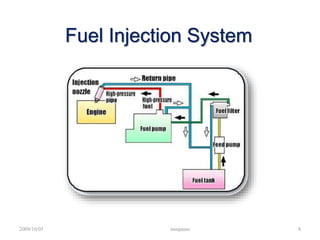

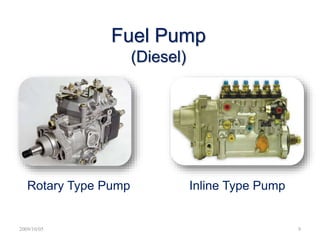

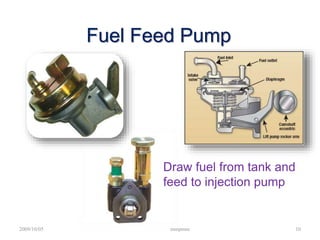

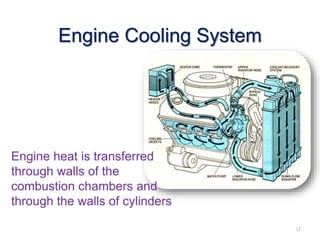

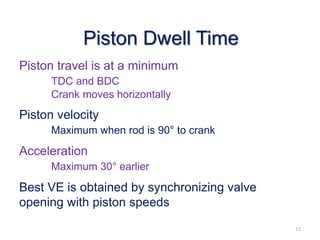

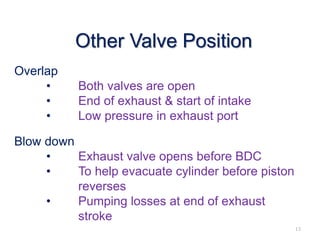

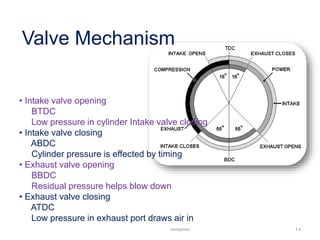

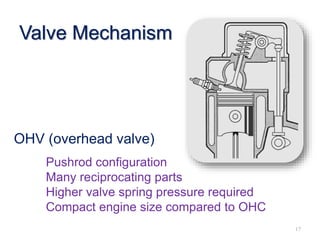

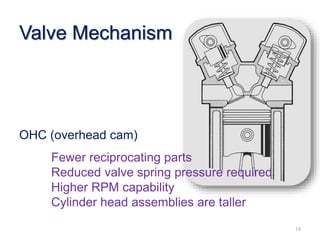

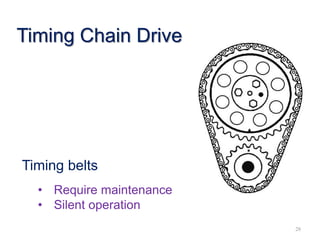

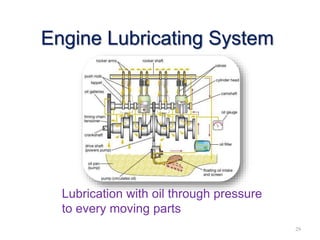

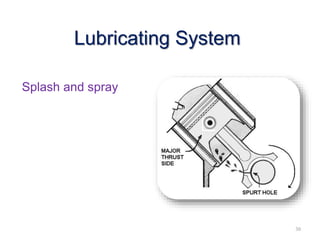

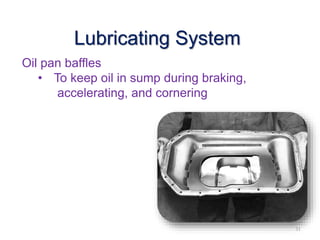

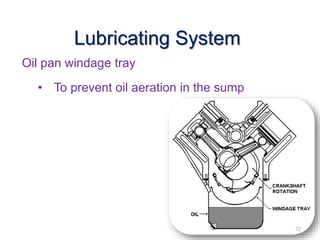

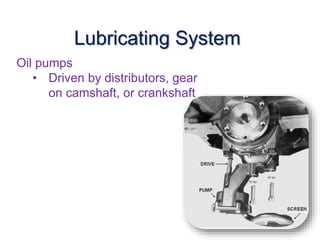

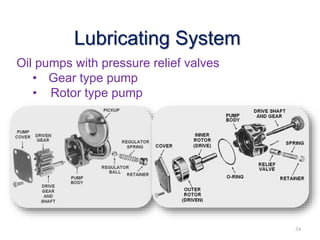

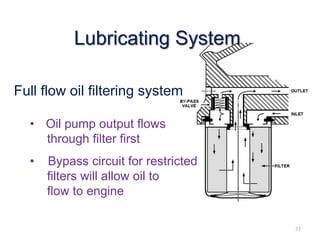

The document describes the operation of a four-stroke engine, including the intake, compression, power, and exhaust strokes in one revolution of the crankshaft. It also discusses the valve timing and fuel injection systems. The cooling, lubrication, and timing systems are described as well as differences between gasoline and diesel engines.