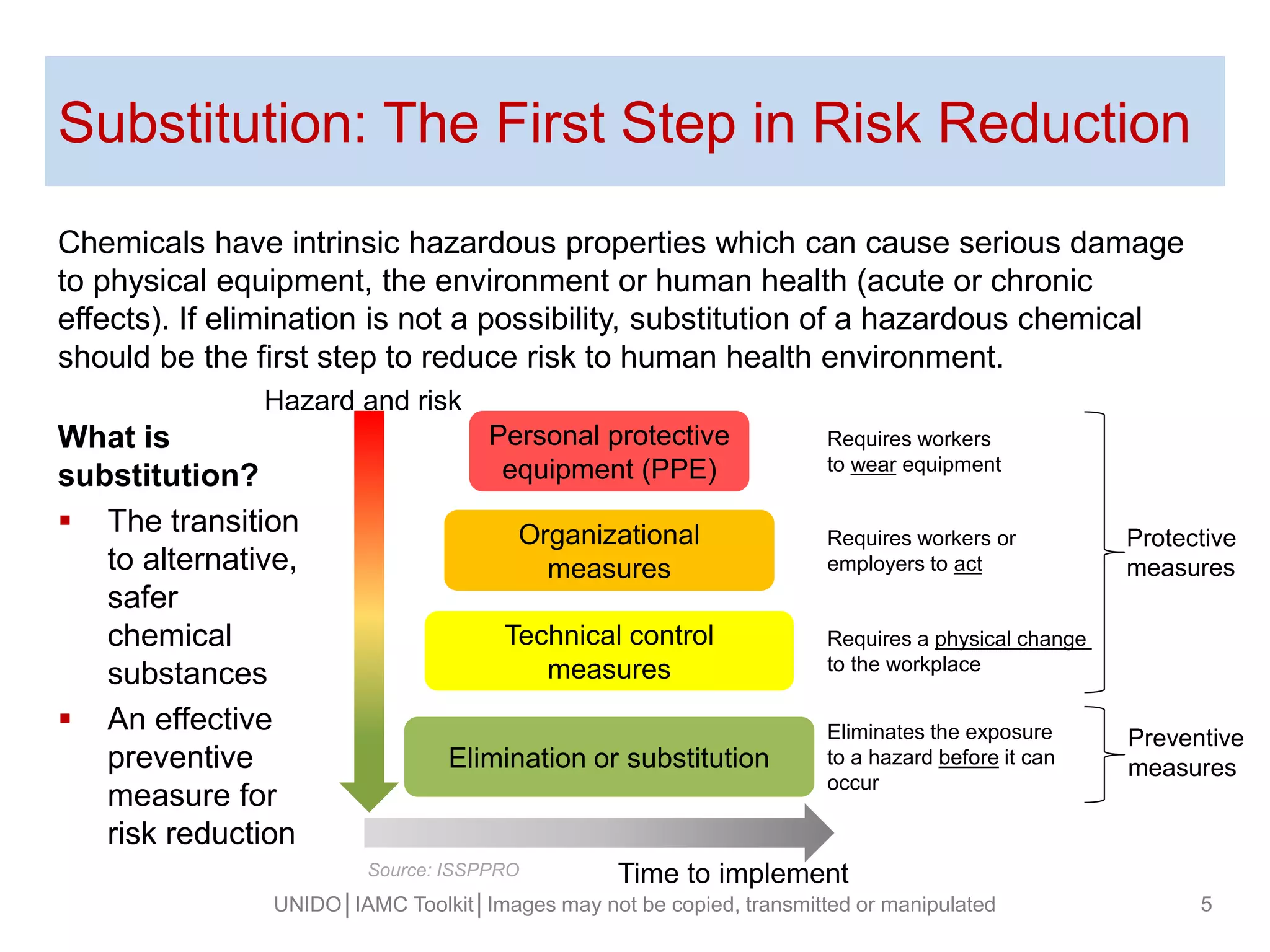

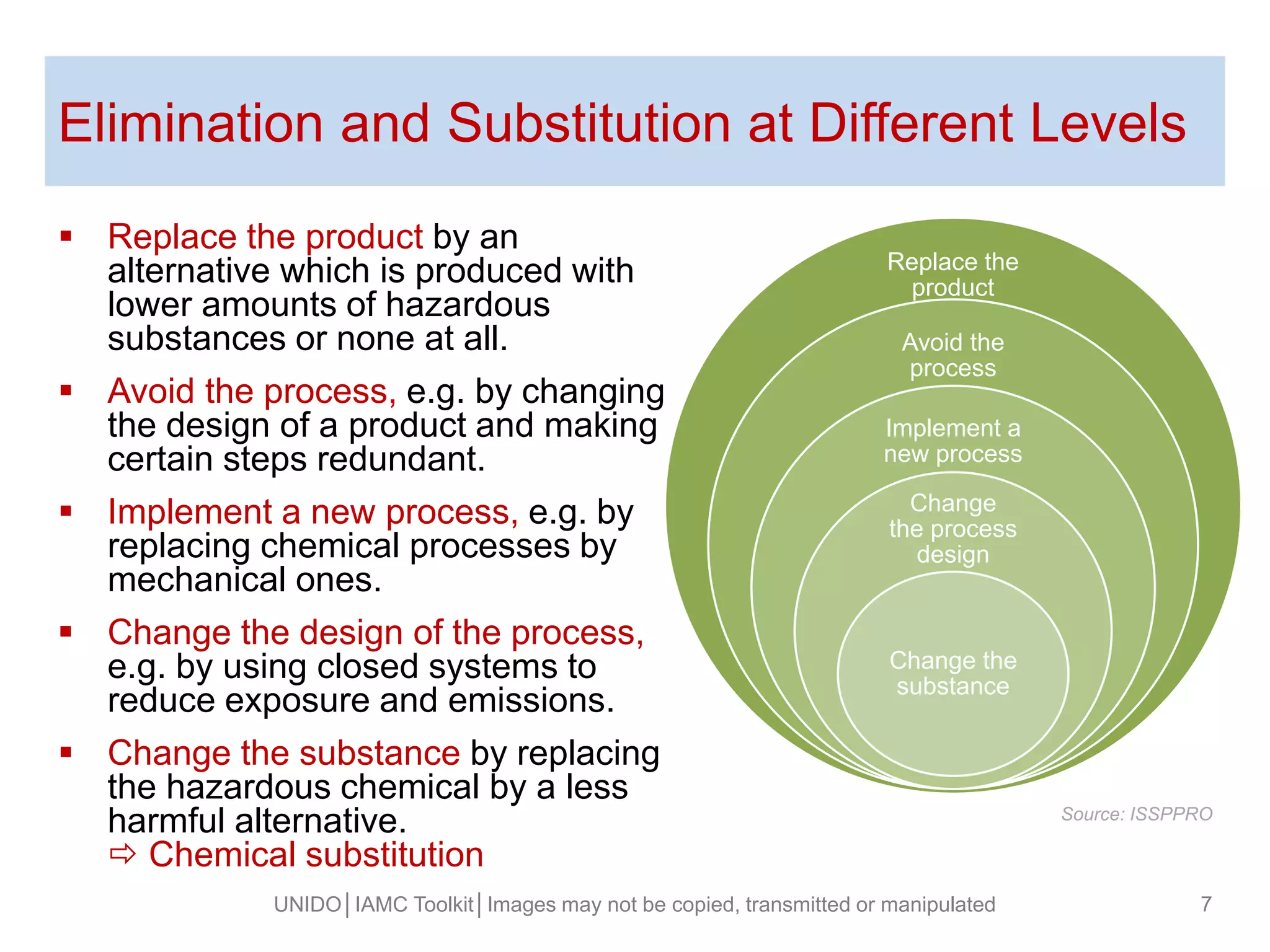

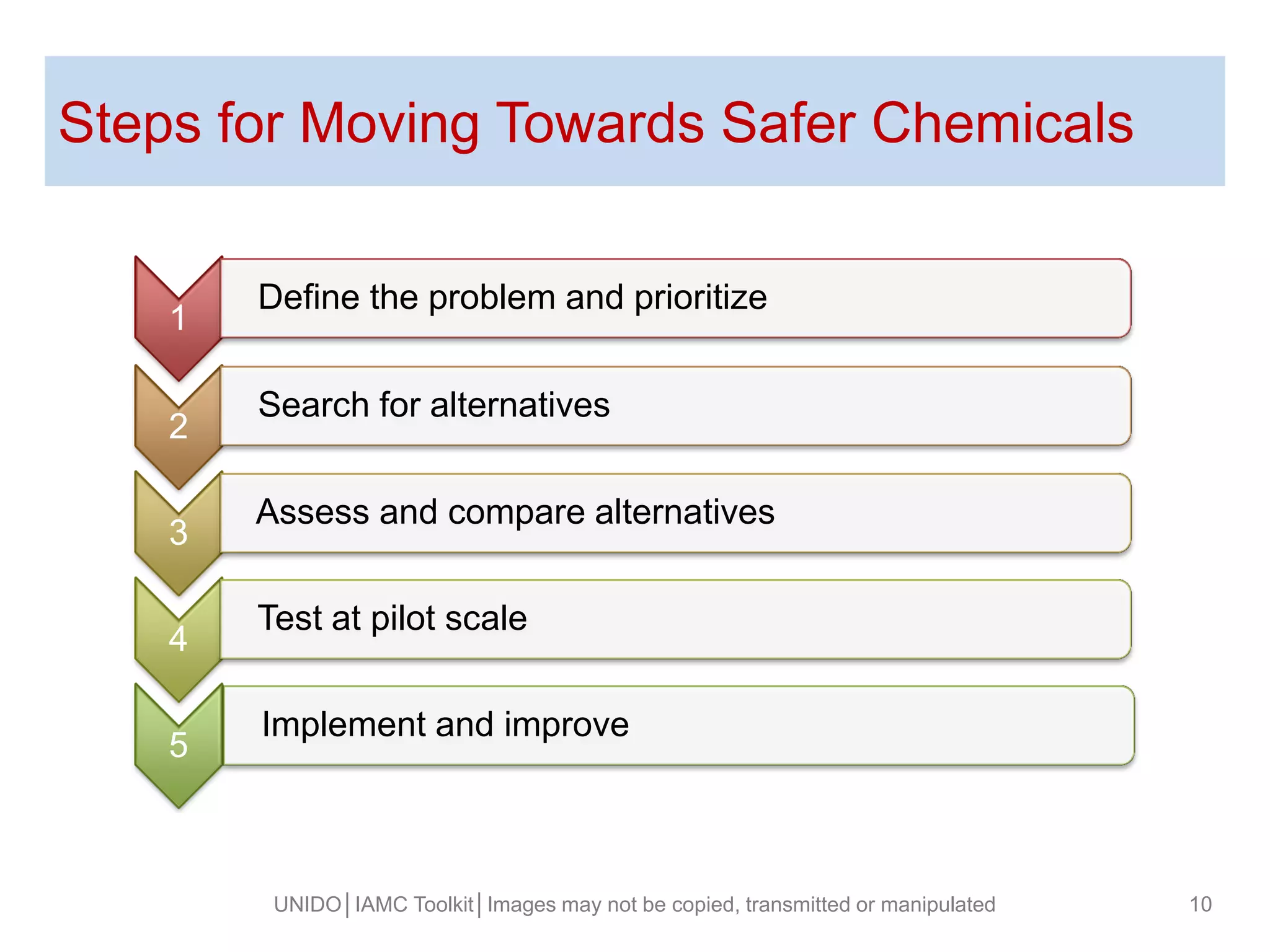

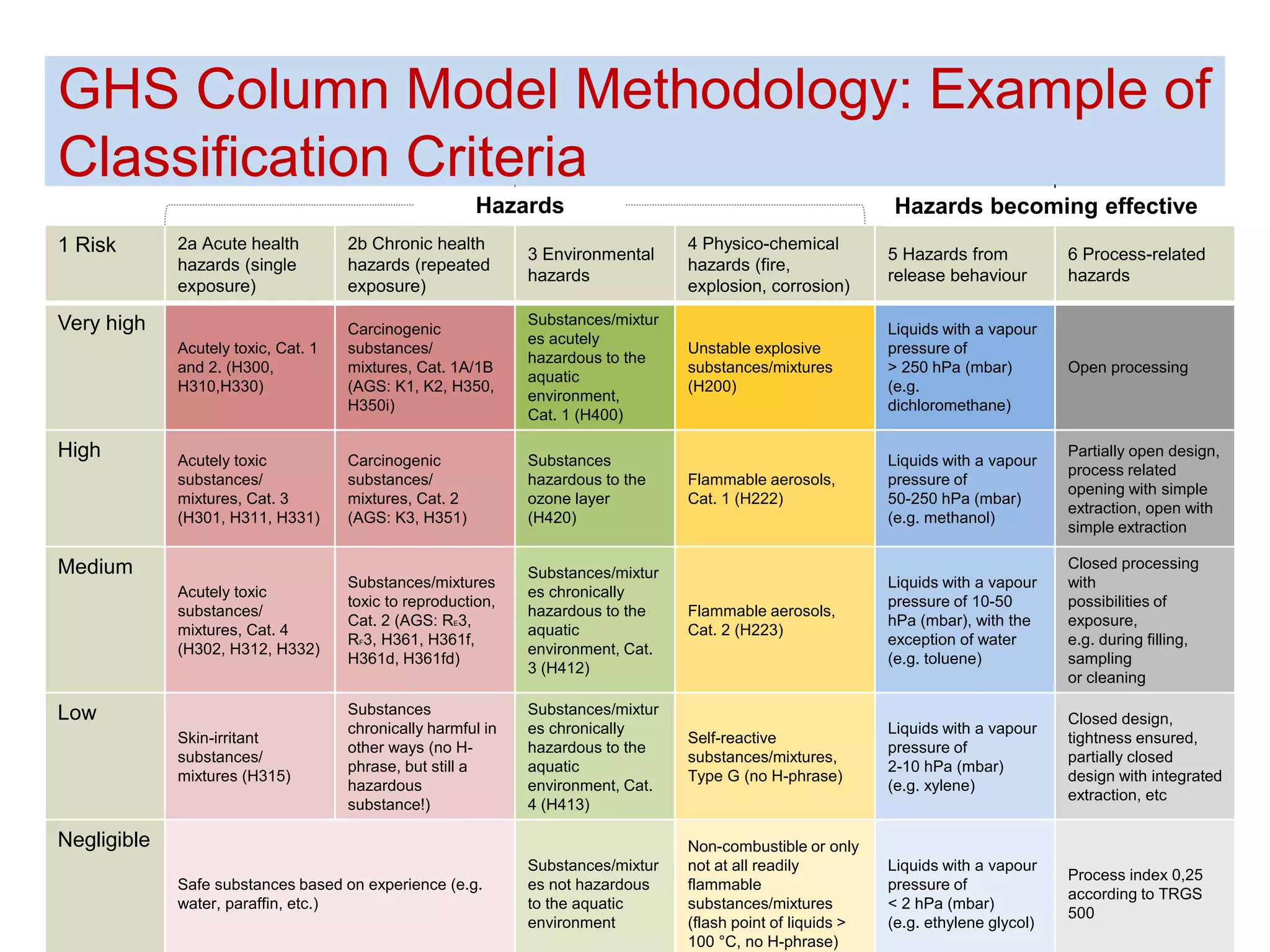

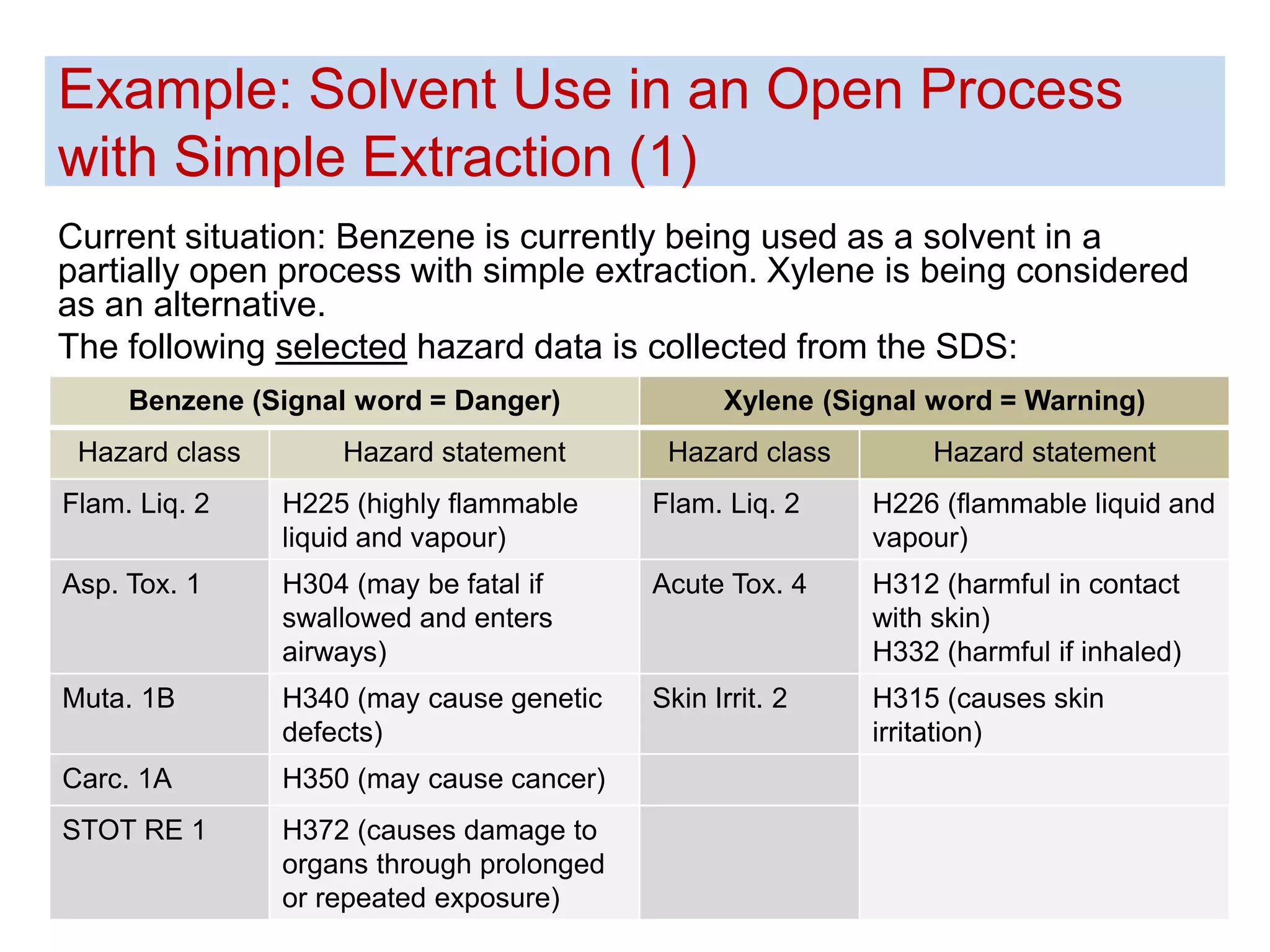

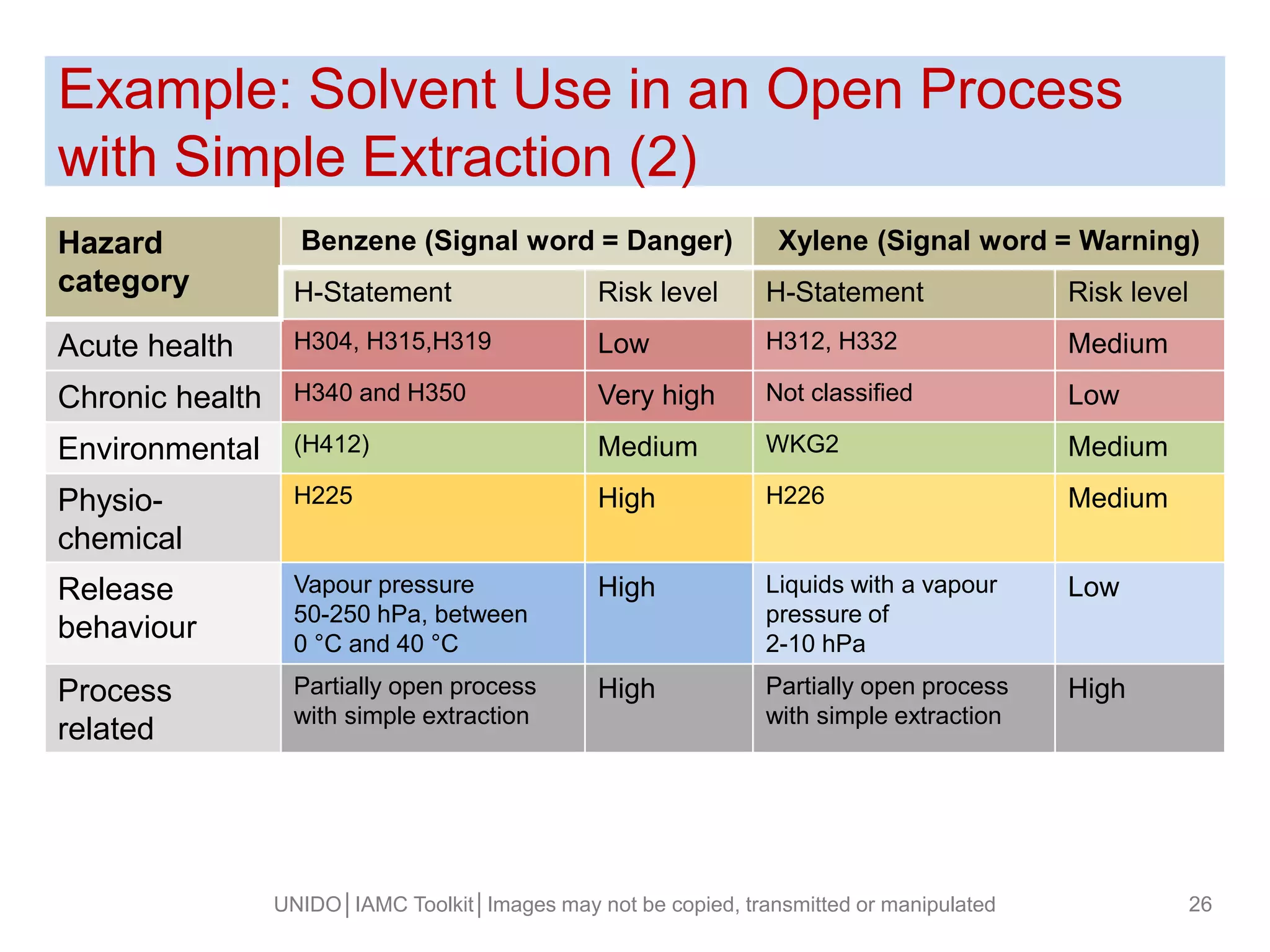

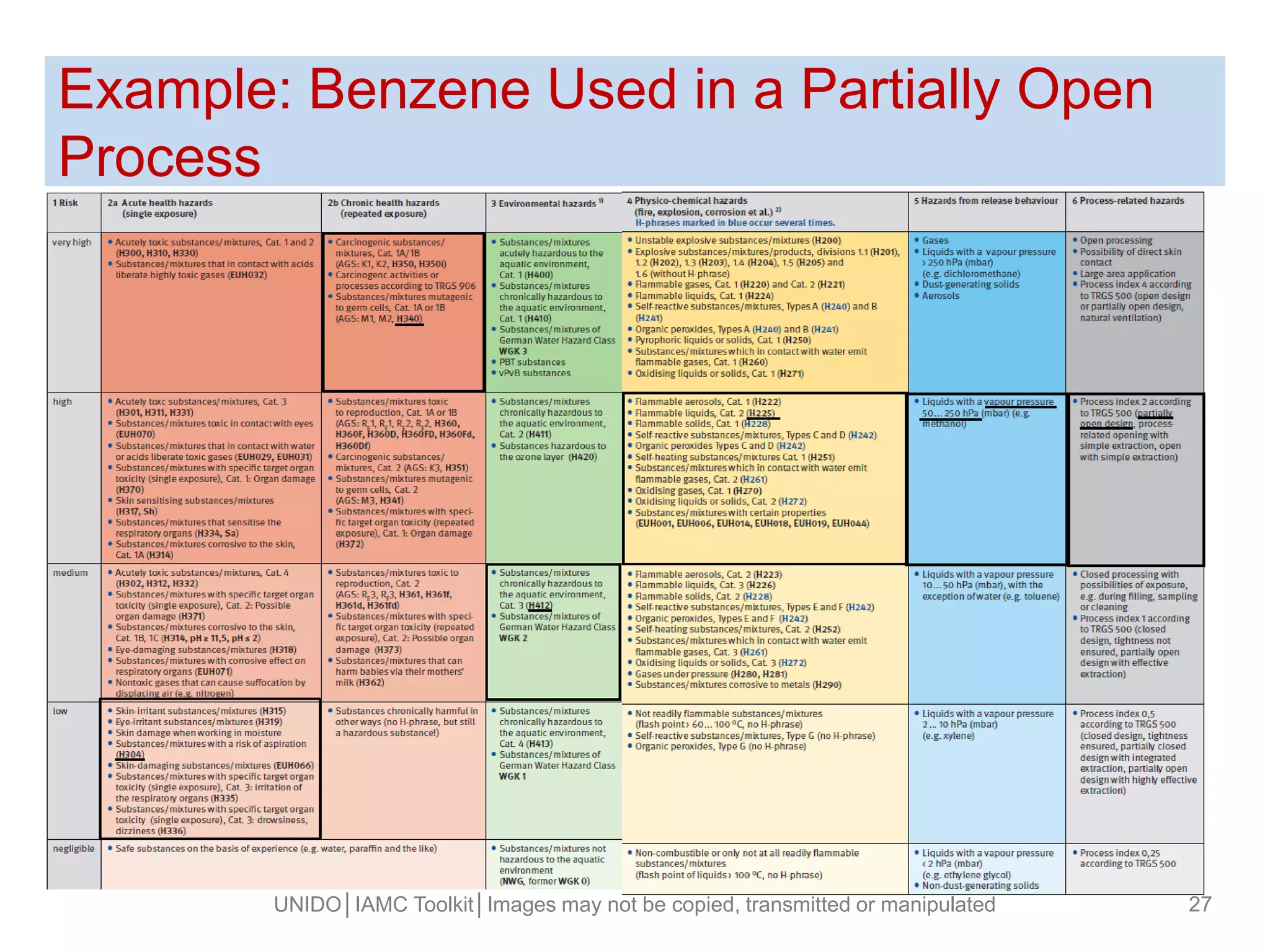

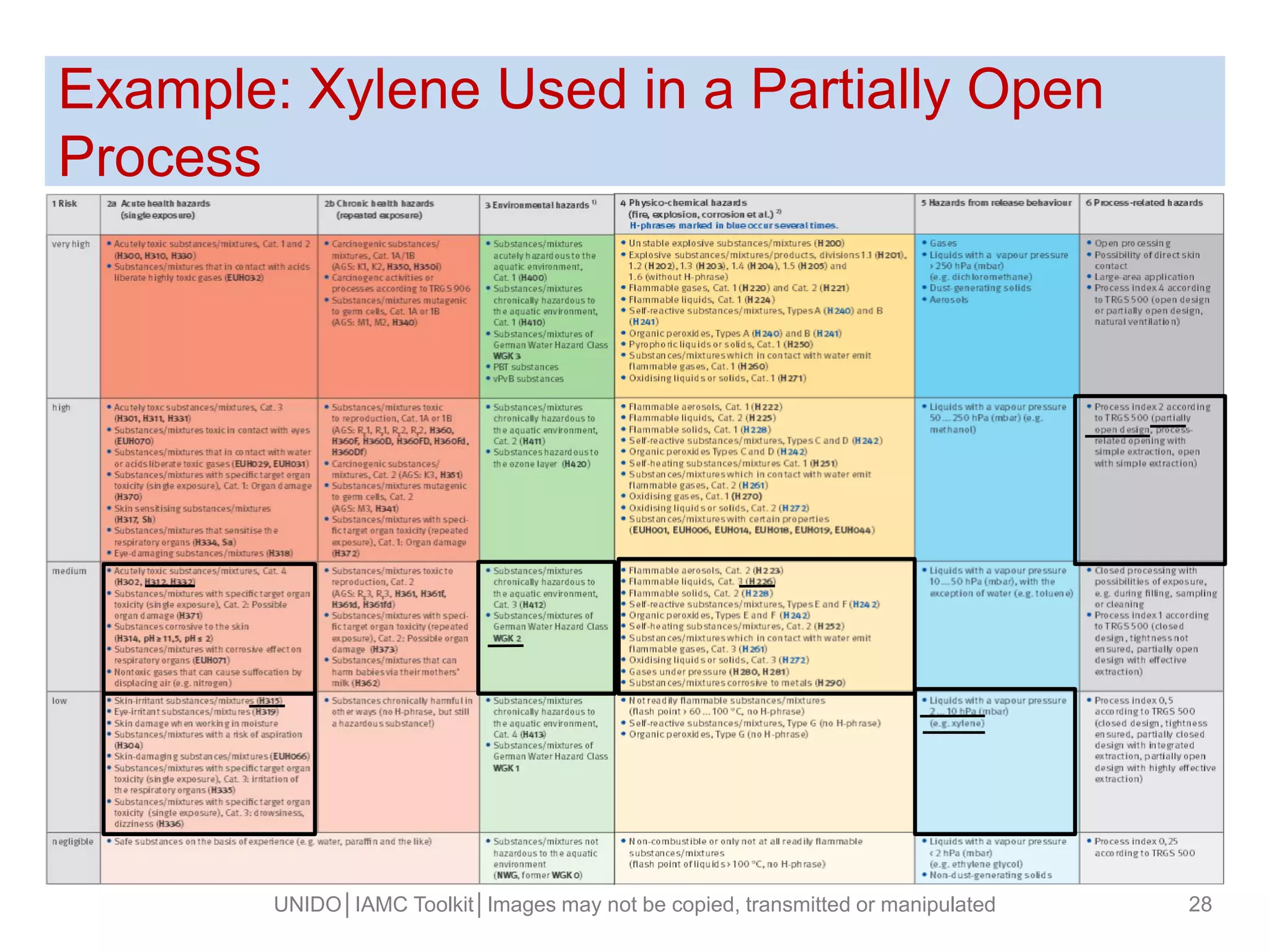

This document provides guidance on assessing and substituting chemicals with safer alternatives. It outlines a 5-step process for moving towards safer chemicals: 1) define the problem and prioritize chemicals, 2) search for alternatives, 3) assess and compare alternatives, 4) test alternatives at a pilot scale, and 5) implement and improve the alternative. It also introduces several tools for comparing chemical hazards, such as the GHS Column Model, which allows comparing the hazards of chemicals based on their GHS classifications and process conditions. The document emphasizes that the goal of substitution is to reduce risks to human health and the environment by transitioning to less hazardous chemical substances and processes.