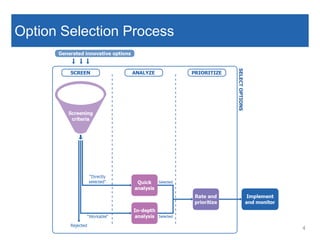

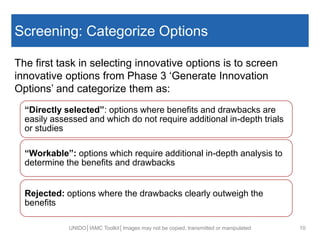

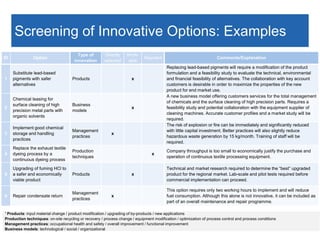

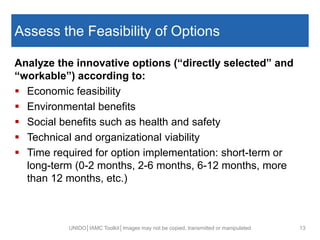

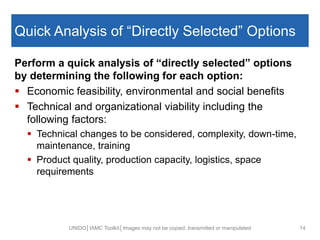

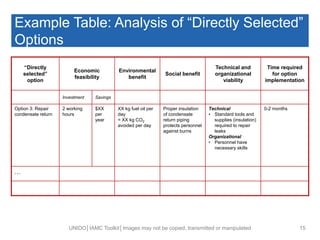

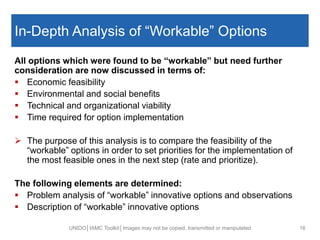

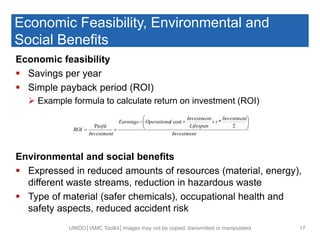

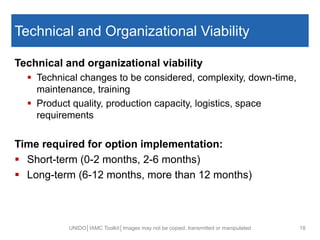

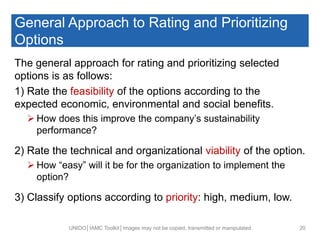

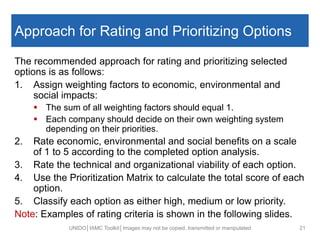

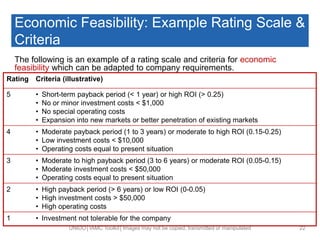

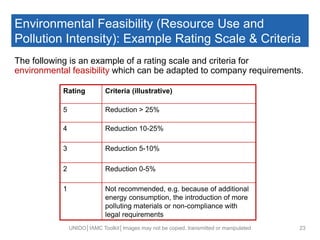

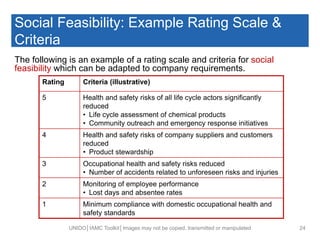

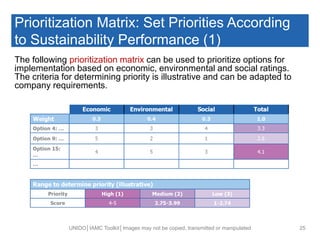

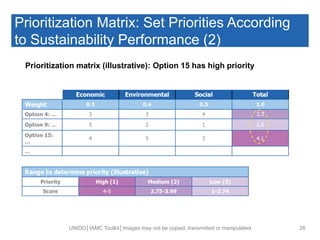

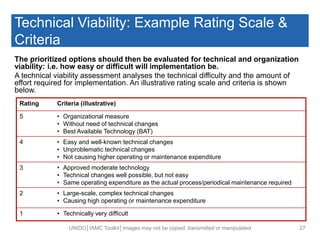

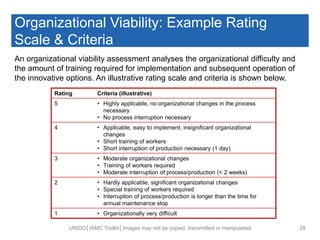

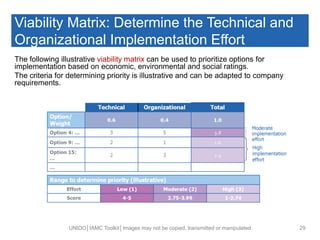

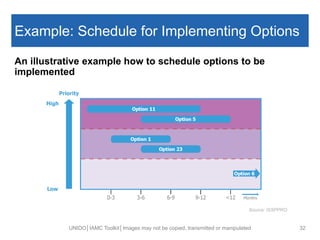

The document outlines the process for selecting innovative options generated in an earlier phase. It involves screening options to determine suitability for further analysis, analyzing economic, environmental and social impacts of suitable options, prioritizing options according to benefits, and scheduling high priority options for implementation. Key steps include using matrices to rate and rank options, considering factors like costs, savings, feasibility and priority to select the options with the highest potential for the company to implement.