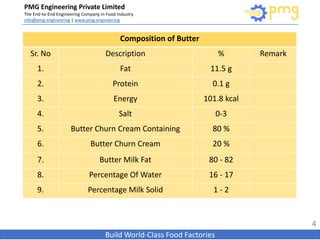

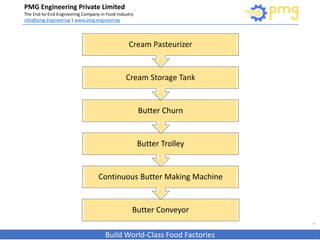

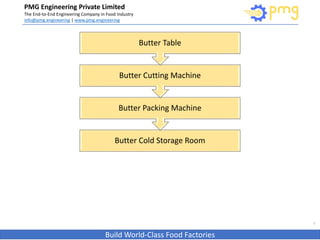

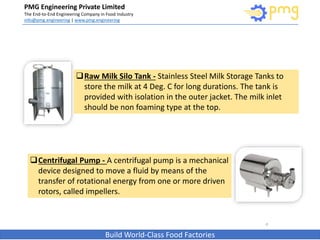

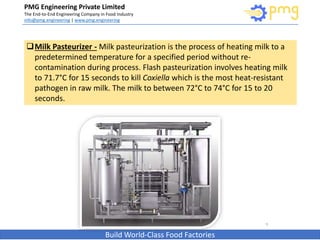

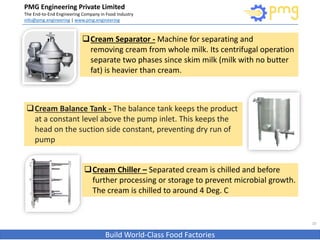

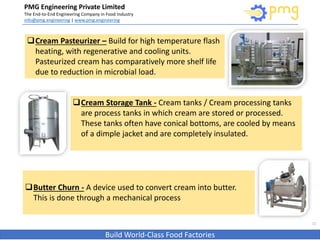

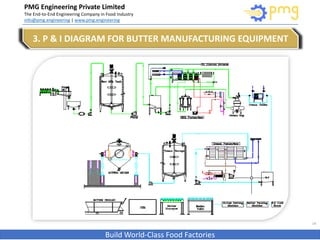

PMG Engineering Private Limited specializes in end-to-end engineering solutions for the food industry, particularly in butter manufacturing. The document details the composition of butter, the equipment involved in the manufacturing process, and provides insights into the engineering design and project management aspects. Reference links for further information on production technology and equipment are also included.