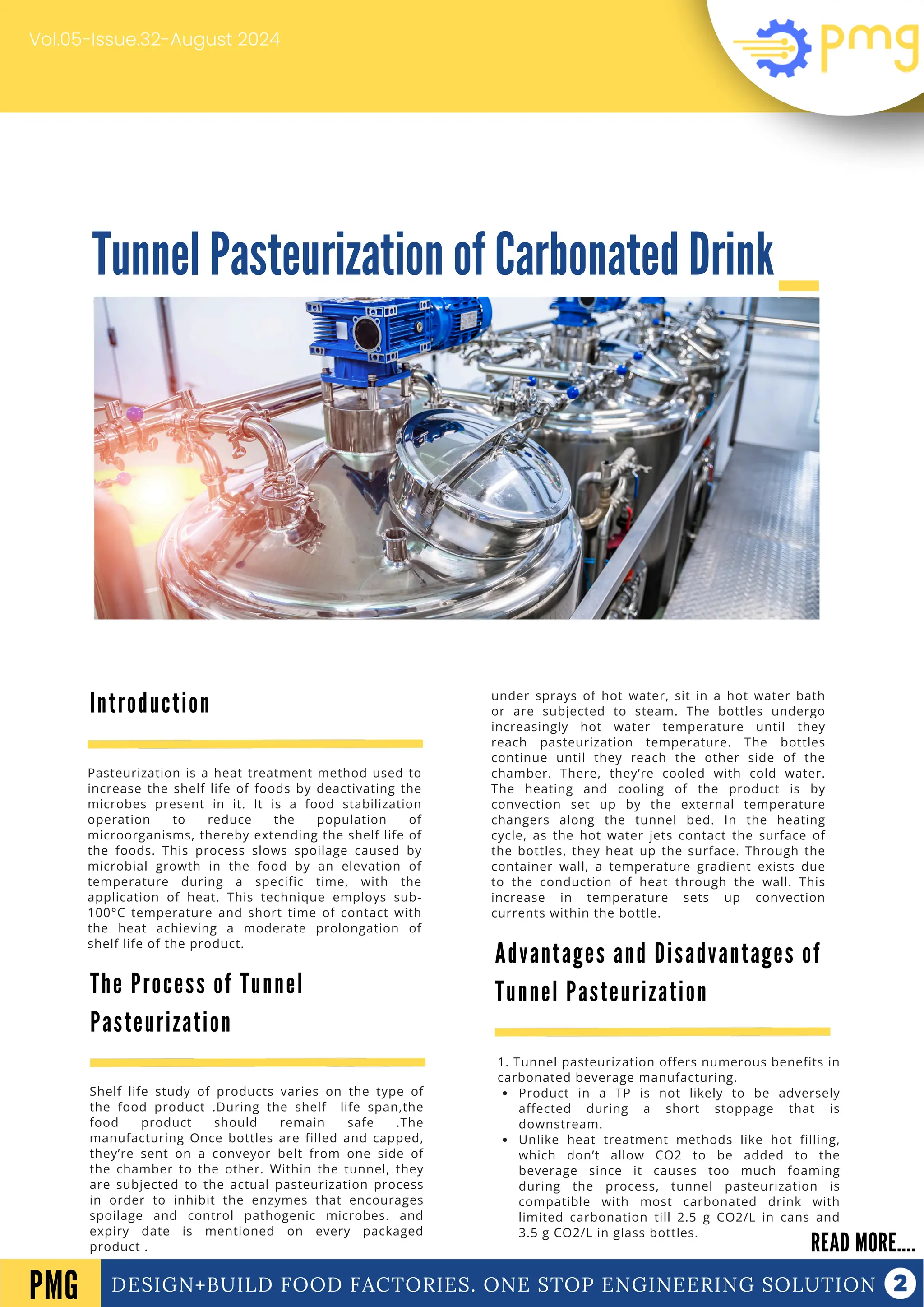

The document discusses various topics related to food processing and industry updates, including the process and advantages of tunnel pasteurization for carbonated beverages and the stages of team development based on Tuckman's model. It highlights a collaboration between Coca-Cola and Oreo to create new products and covers initiatives like FSSAI's project on microplastic contamination and the launch of India's first 24/7 grain dispensing ATM. Additionally, it emphasizes the importance of teamwork and innovation in the food industry.