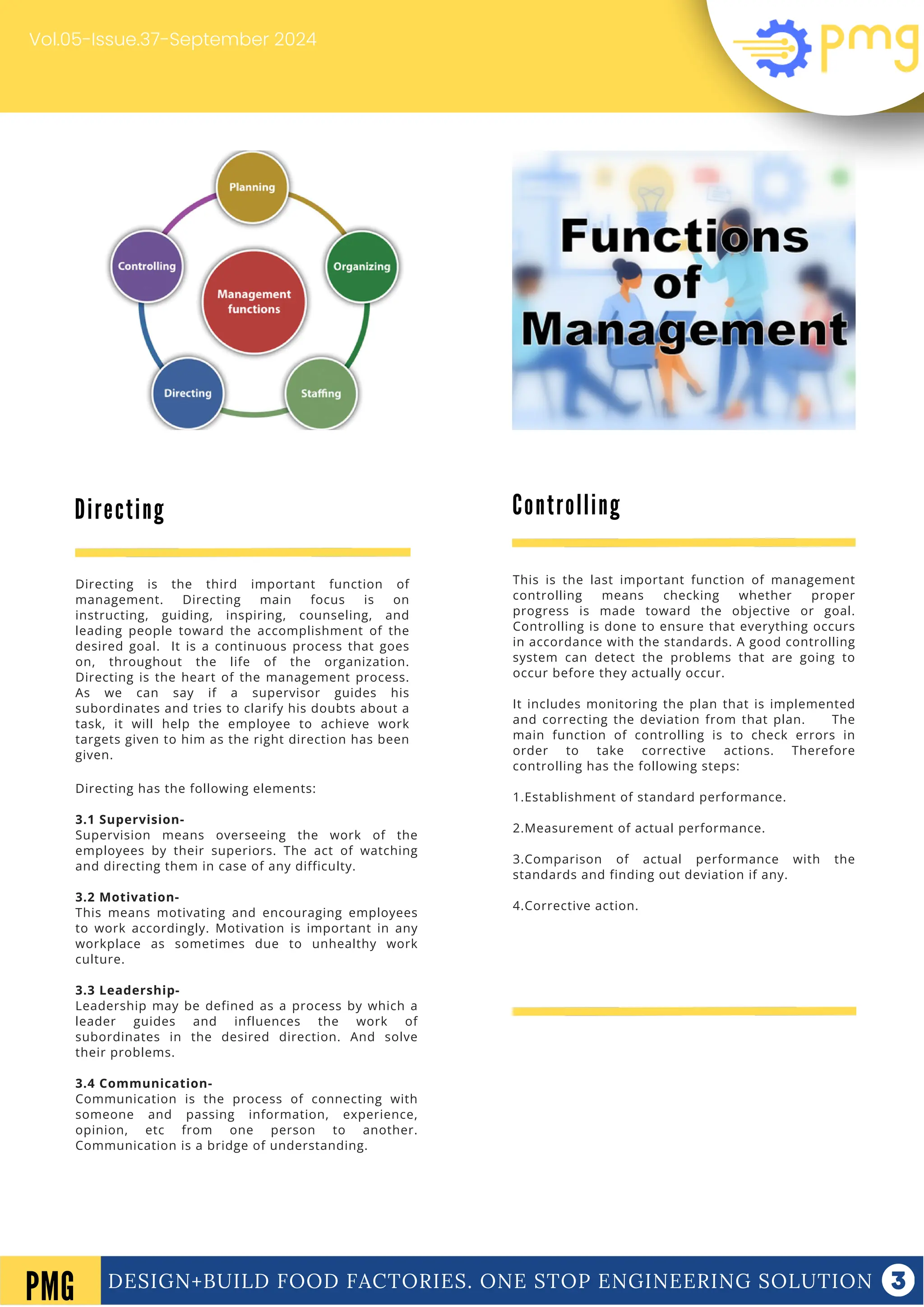

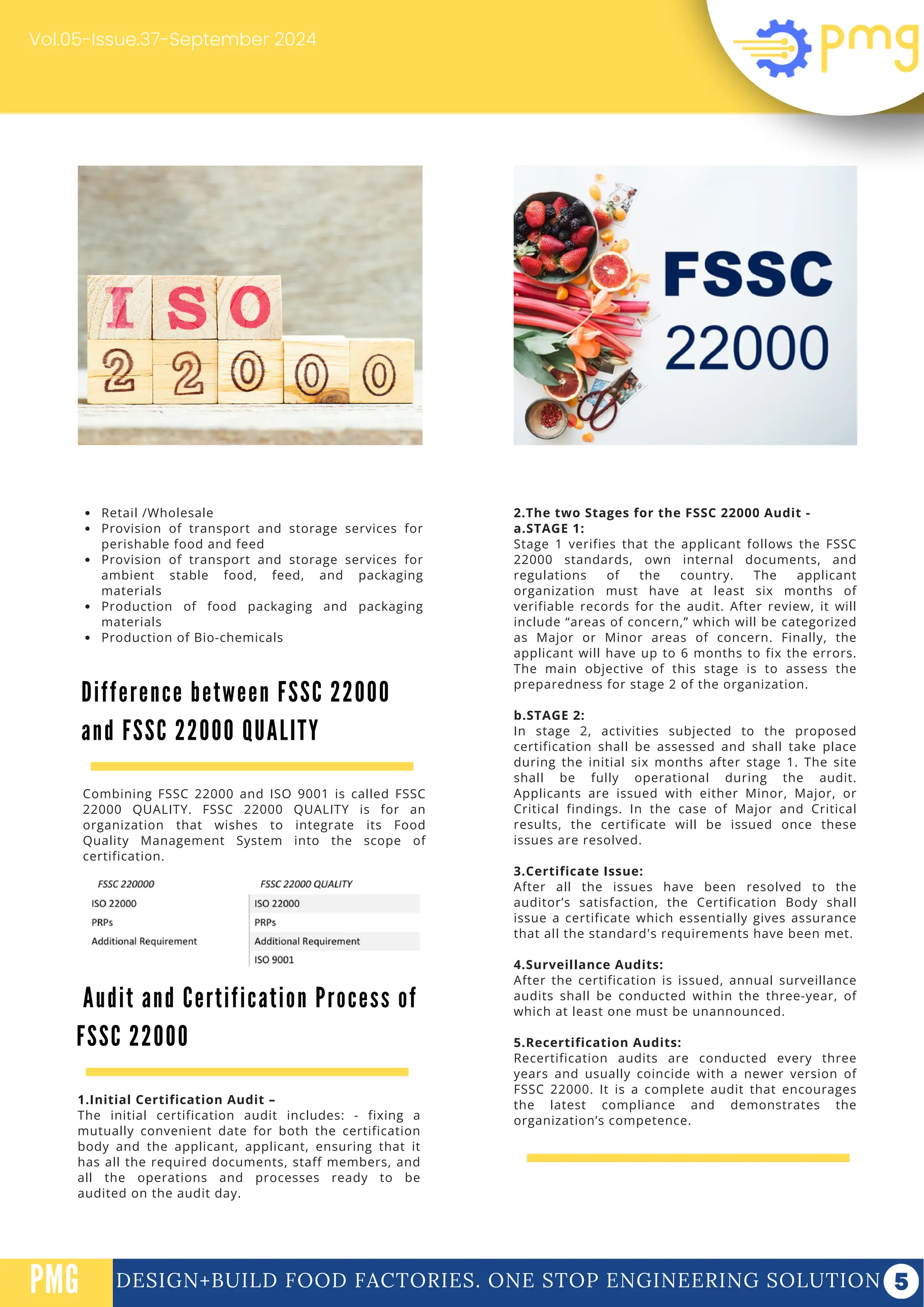

The document discusses the management principles and functions critical for efficiently running organizations, particularly in the food and beverage industry. It highlights planning, organizing, directing, and controlling as essential management functions, along with an overview of the FSSC 22000 certification for food safety management. Additionally, the document covers recent industry developments, including government inquiries into price increases for edible oils and a summary of the World Food India 2024 event.