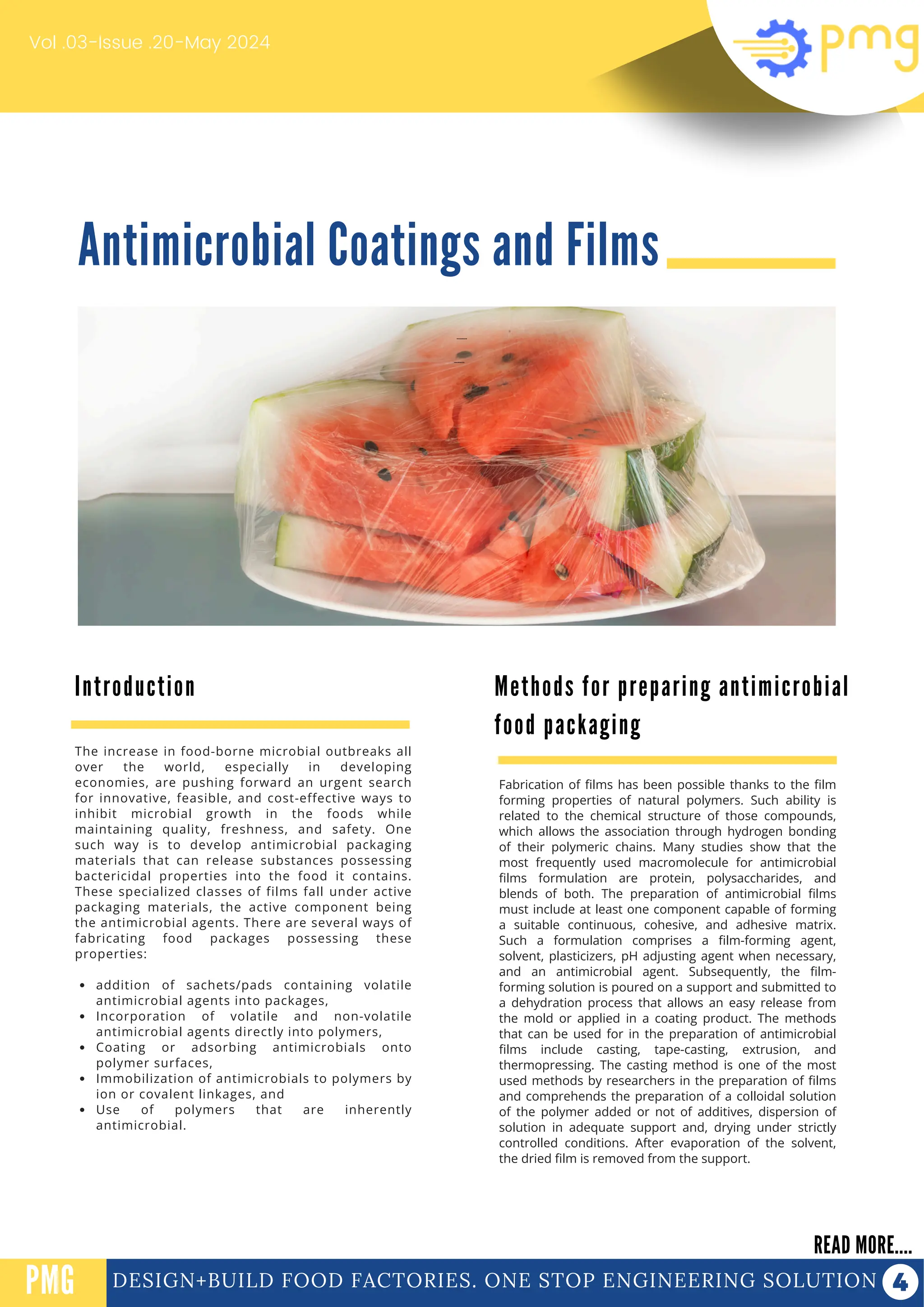

The document is a newsletter discussing engineering solutions for designing and building food factories, emphasizing the importance of project management in achieving project goals through planning, execution, and monitoring. It highlights advancements in antimicrobial packaging, which aims to enhance food safety by preventing microbial growth, and discusses recent regulatory issues in the food industry, including the use of unsafe chemicals in food production. Additionally, it features updates on the dairy industry's impact on financial inclusion and the need for better nutritional practices worldwide.