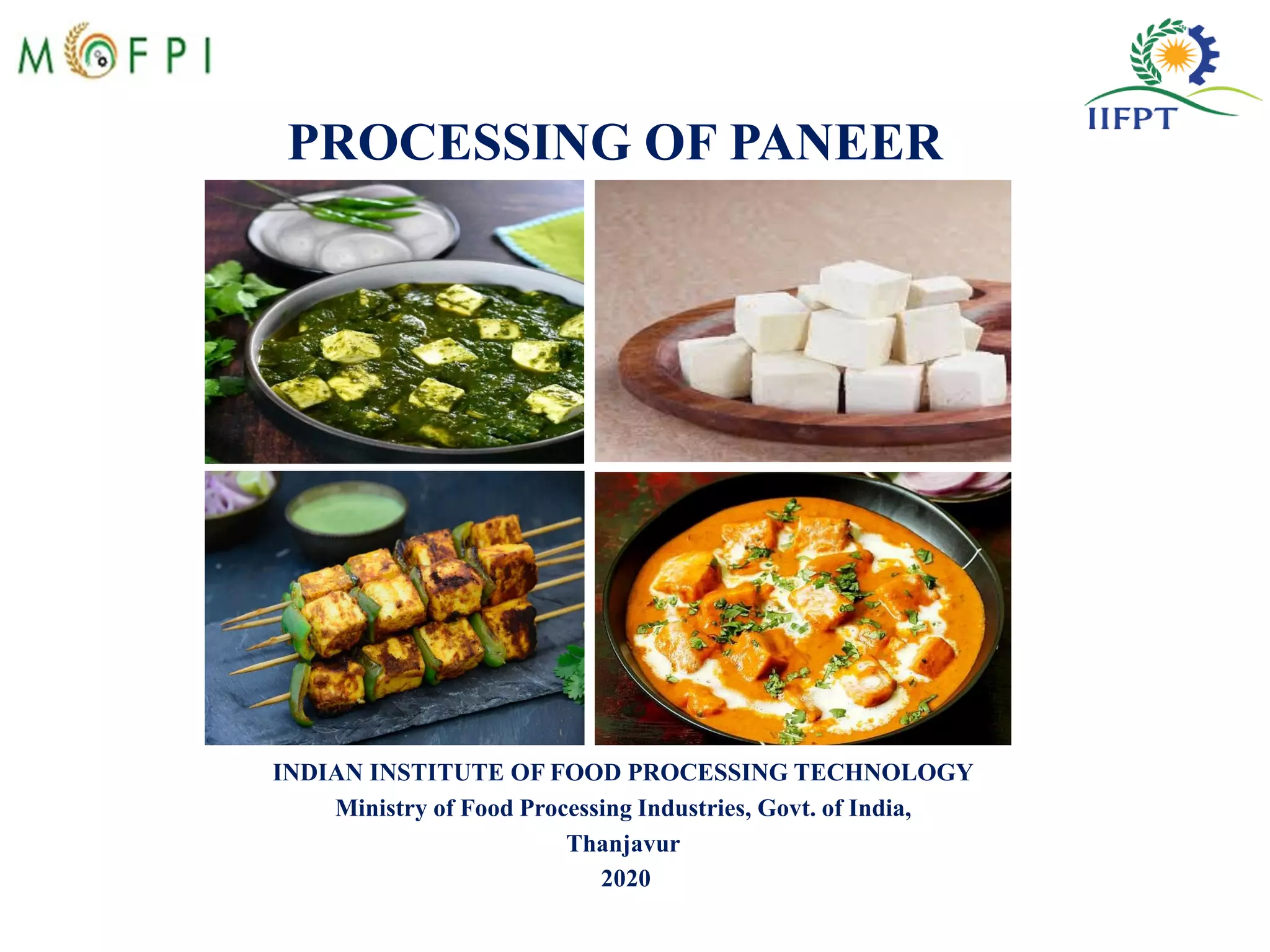

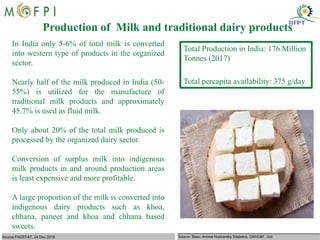

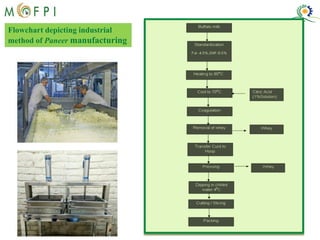

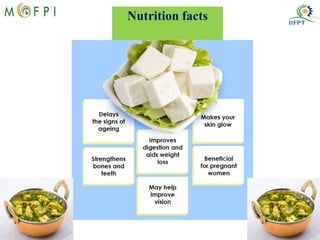

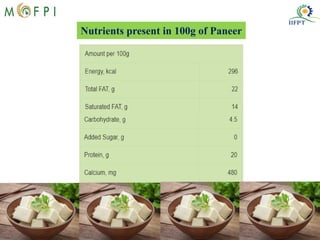

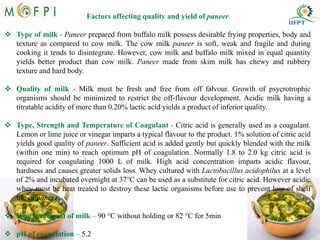

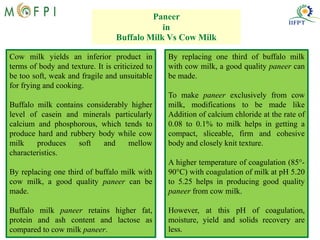

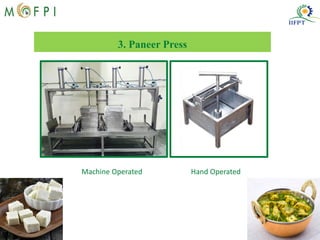

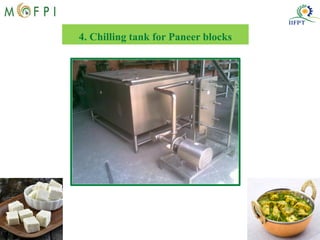

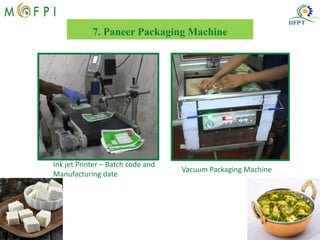

This document provides information on the processing of paneer, an Indian cheese made by coagulating milk using acids. It discusses the traditional production of paneer in India, noting that about 5% of India's annual milk production is converted to paneer. The document outlines the industrial process for making paneer, including heating the milk, adding an acid like citric acid to coagulate it, filtering and pressing the curds. It compares paneer made from buffalo milk versus cow milk. Finally, it lists the key equipment used in industrial paneer production like vats, hoops, presses and packaging machines.