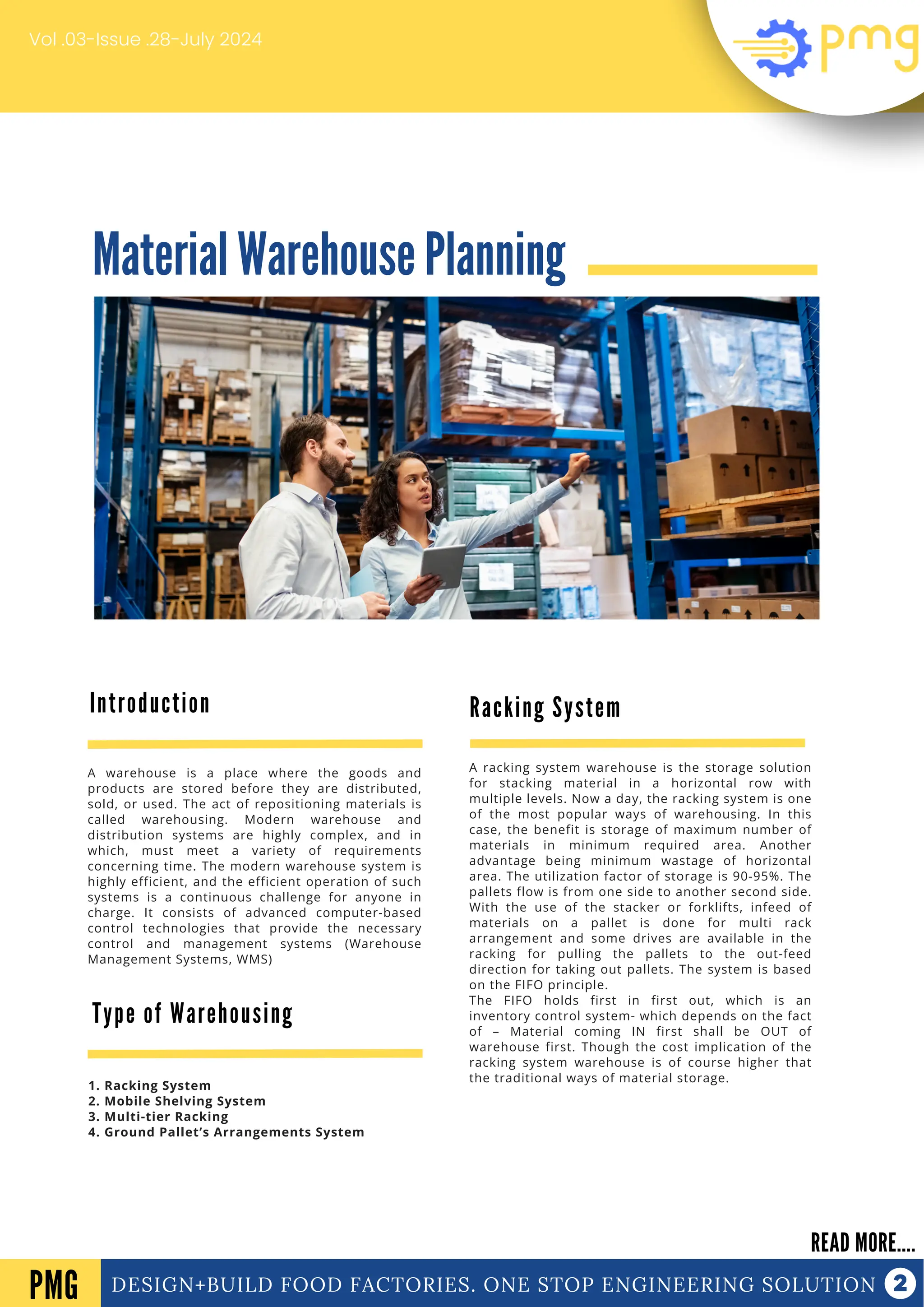

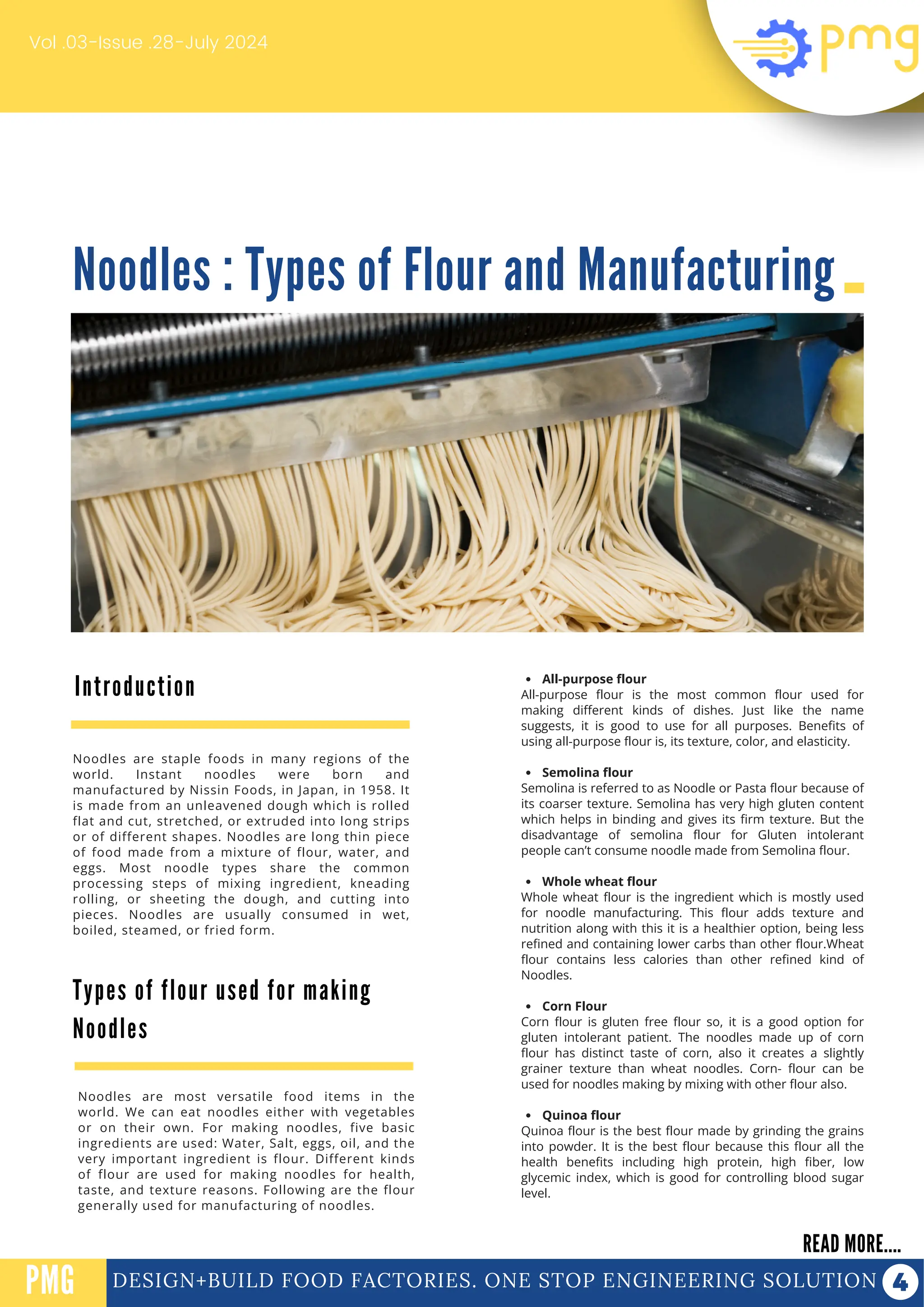

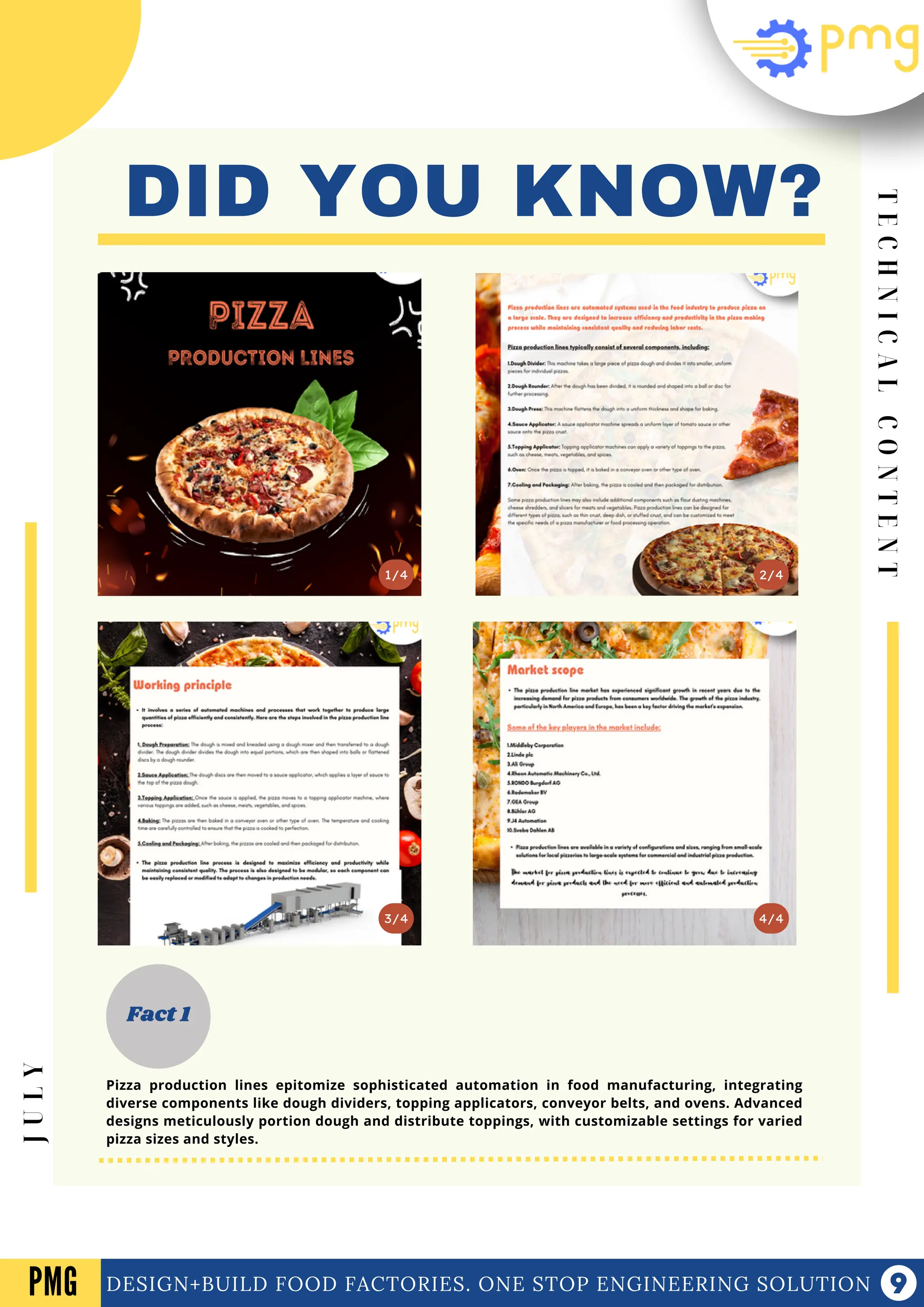

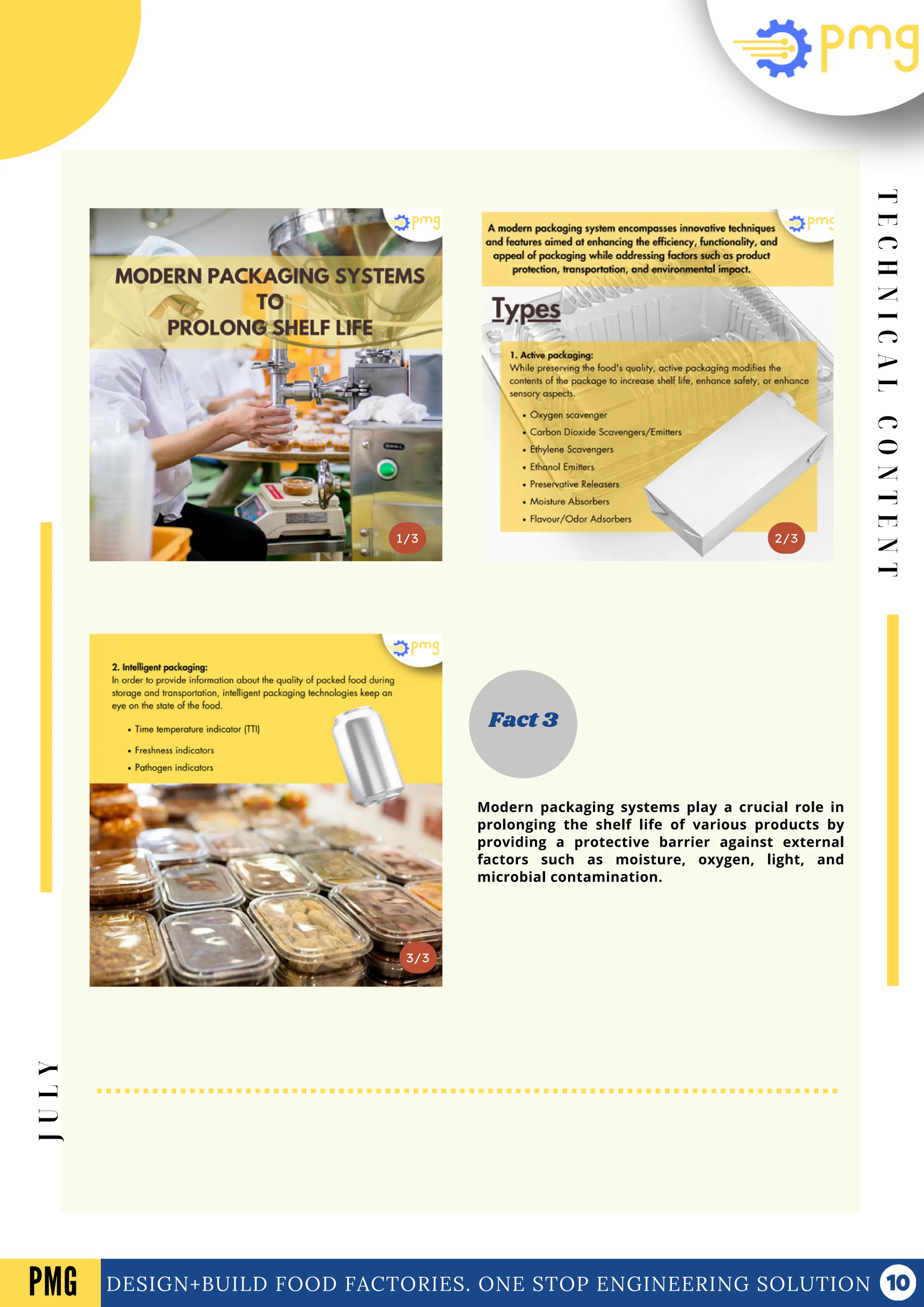

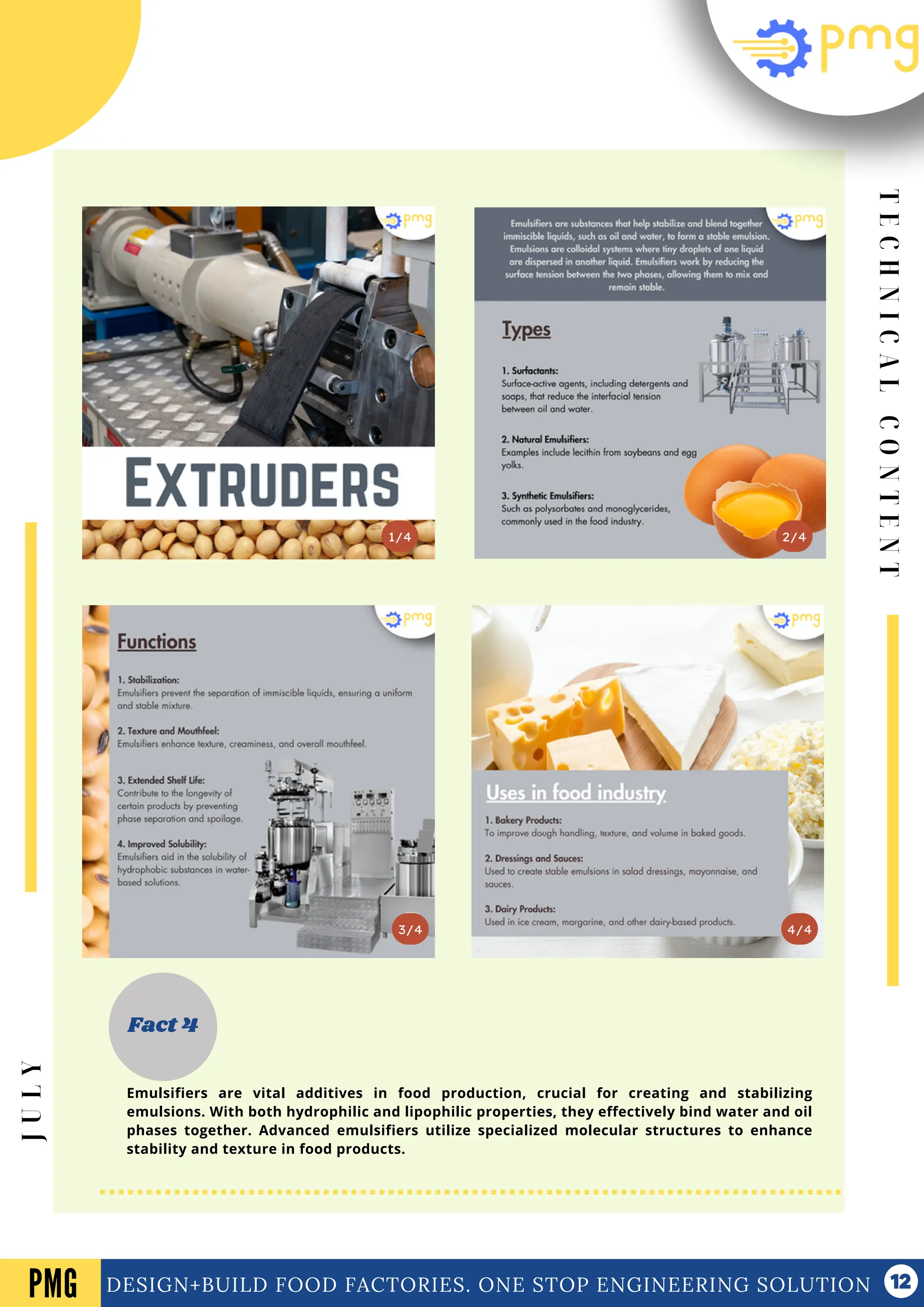

The document discusses various aspects of the food production and warehousing industry, focusing on design and engineering solutions for food factories. It covers topics such as types of warehousing systems, the processing of noodles including different flours used, and innovative research in food safety. Additionally, it highlights current industry news, including sustainable food practices and consumer trends influenced by the pandemic.