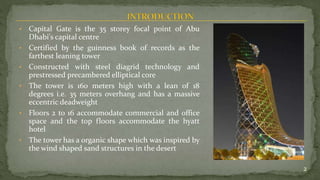

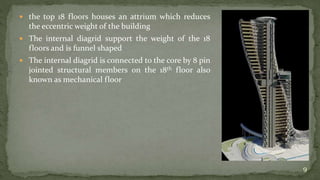

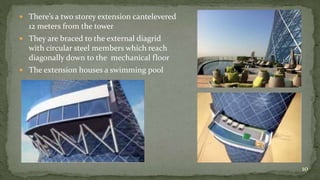

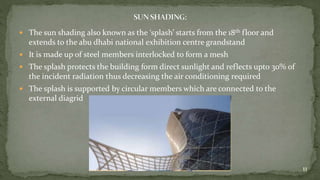

Capital Gate is a 35-storey tower in Abu Dhabi, notable for being the world's furthest leaning structure at an 18-degree angle. Completed in 2011, it houses the Hyatt Capital Gate hotel and 15,000 square meters of office space, all constructed using advanced steel diagrid technology and unique architectural design. The project has become a symbol of Abu Dhabi's progress and integrates with the Abu Dhabi National Exhibition Centre, enhancing its significance in the region.