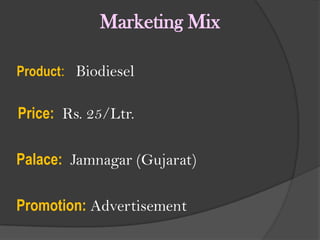

This business plan proposes producing and selling biodiesel in India. There is a need for eco-friendly and domestic fuels to reduce dependence on foreign oil and emissions. Biodiesel can be produced from crops like jatropha and has similar properties to conventional diesel. The plan involves researching production technologies, testing biodiesel in engines, and quality control procedures to produce biodiesel that meets standards. Initially the biodiesel would be sold to fleet operators and eventually to larger car manufacturers and distributors with a goal of growing export sales by 30% annually over 3 years.