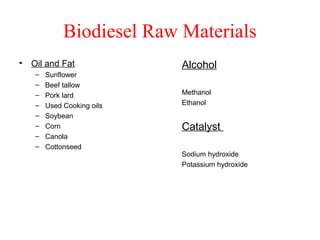

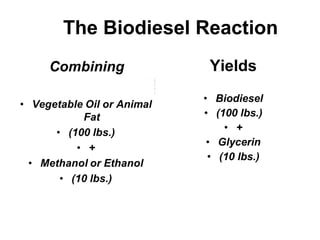

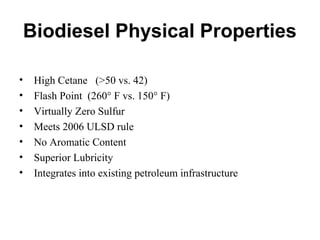

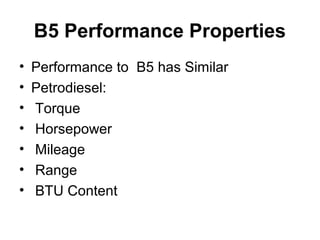

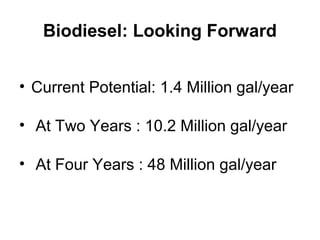

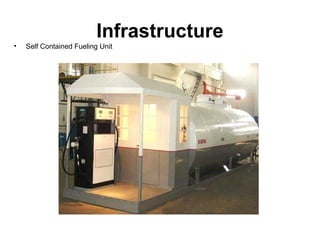

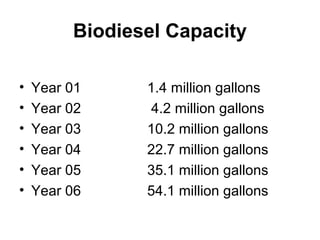

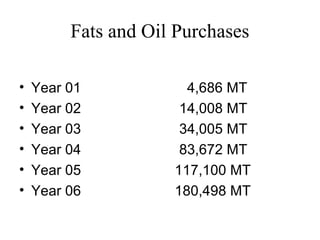

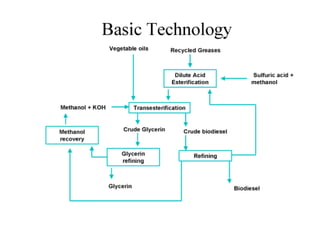

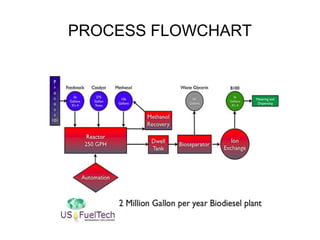

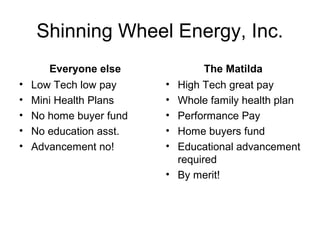

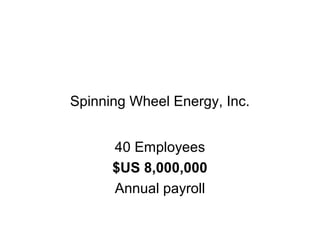

The document discusses plans to build a biodiesel plant called "The Matilda" in Puerto Rico. It will initially produce 1.4 million gallons per year and ramp up to over 50 million gallons per year within 6 years. It will create high-paying jobs and benefit the local economy. The plant will use local waste oils and fats as feedstock and will use a compact, self-contained production unit that is carbon neutral and engine friendly.