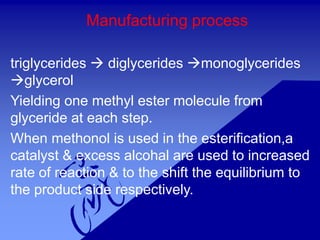

This document discusses biodiesel as an alternative fuel. It provides information on the manufacturing process, advantages, applications and future scope of biodiesel. The manufacturing process involves transesterification of triglycerides into biodiesel using methanol and a catalyst. Biodiesel has advantages like being usable in standard diesel engines without modifications, being non-polluting and producing fewer emissions than conventional diesel. It can be used for applications like fueling vehicles, generating electricity and removing paint or grease. The future scope of biodiesel is promising as a replacement for petroleum diesel given its renewable nature and cleaner burning characteristics.