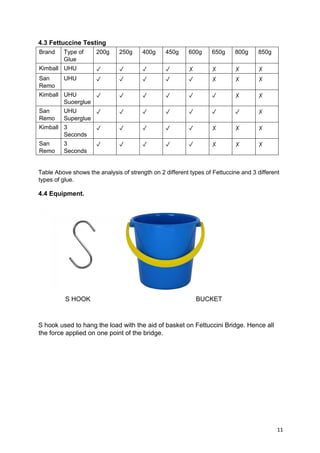

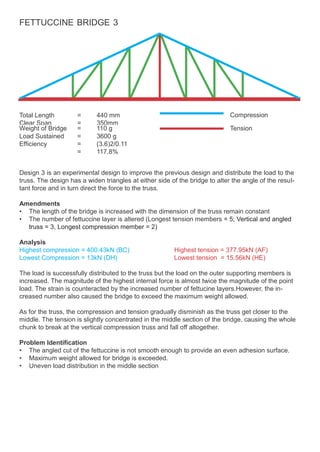

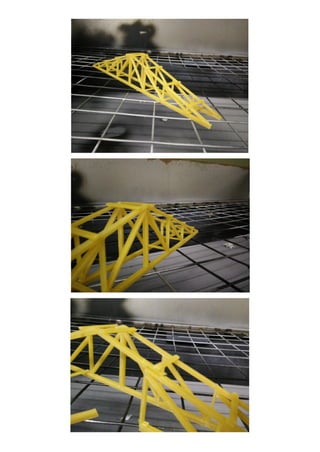

The document discusses the design and construction of a fettuccine truss bridge with a clear span of 350mm and weight limit of 180g by a group of 7 students. It includes sections on precedent studies of truss bridges, material testing and selection, structural analysis, model making methodology, and efficiency calculations. The goal is to design a truss bridge with high aesthetic value, minimal materials, and understanding of load distribution and tension/compression members in a truss.