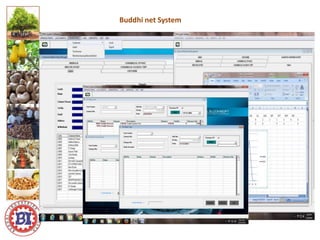

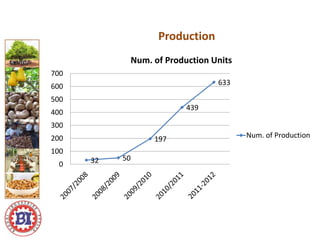

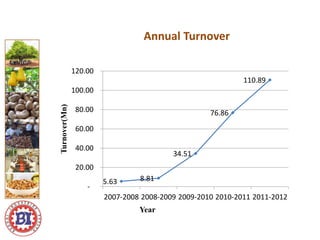

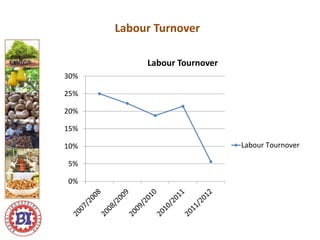

This document summarizes Buddhi Industries' implementation of best practices to improve their cashew processing operations from 2010-2012. It describes how they standardized processes, increased production capacity and turnover, reduced labor turnover, and achieved ISO 9001:2008 certification through initiatives like kaizen, 5S, line balancing, and developing computerized procedures. The results were measurable improvements in key metrics as well as unmeasurable benefits like an improved work environment and employee satisfaction. The National Productivity Secretariat provided support through training programs, consultancy, and site visits that helped enable Buddhi Industries' process improvements across their organization.