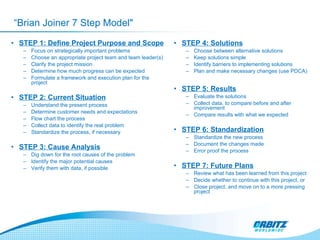

The document discusses the concept of Kaizen, or continuous improvement, and how it can be applied to operations teams to achieve higher quality and eliminate waste. It provides background on the origins and principles of Kaizen in Japanese manufacturing. Key aspects include focusing on process improvement over results alone, taking a systemic view, and avoiding blame. Methods like PDCA (Plan-Do-Check-Act) and focusing on small, incremental changes are emphasized. The document argues that cross-training, reducing redundancies, and viewing problems as opportunities for improvement have helped the operations team discussed provide better service through Kaizen.