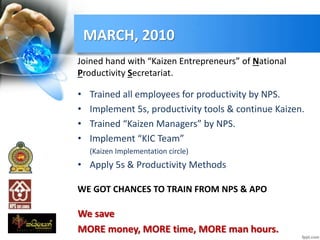

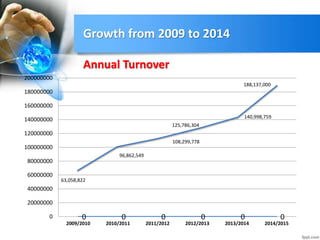

The document outlines the growth and transformation of the Mount Group of Companies, highlighting their strategies to enhance production quality and efficiency through the implementation of productivity methods and new technology. The company shifted from producing low-quality 'B' grade cartons to 'A' grade, significantly improving customer satisfaction and achieving higher annual turnover from 2009 to 2014. Future plans include achieving ISO certifications and becoming the leading packaging company by 2020.